July 30, 2024

In order to analyze sensor data more accurately and to follow up the health of the machine in more detail, some features of the machine must be known in addition to the equipment information. For this reason, a separate section has been added to the Machine Editor, and an area has been added where these machine properties can be easily entered into the system. This information received has been reflected to the necessary points of the system, and users have been provided with easy access to the information on the pages they need.

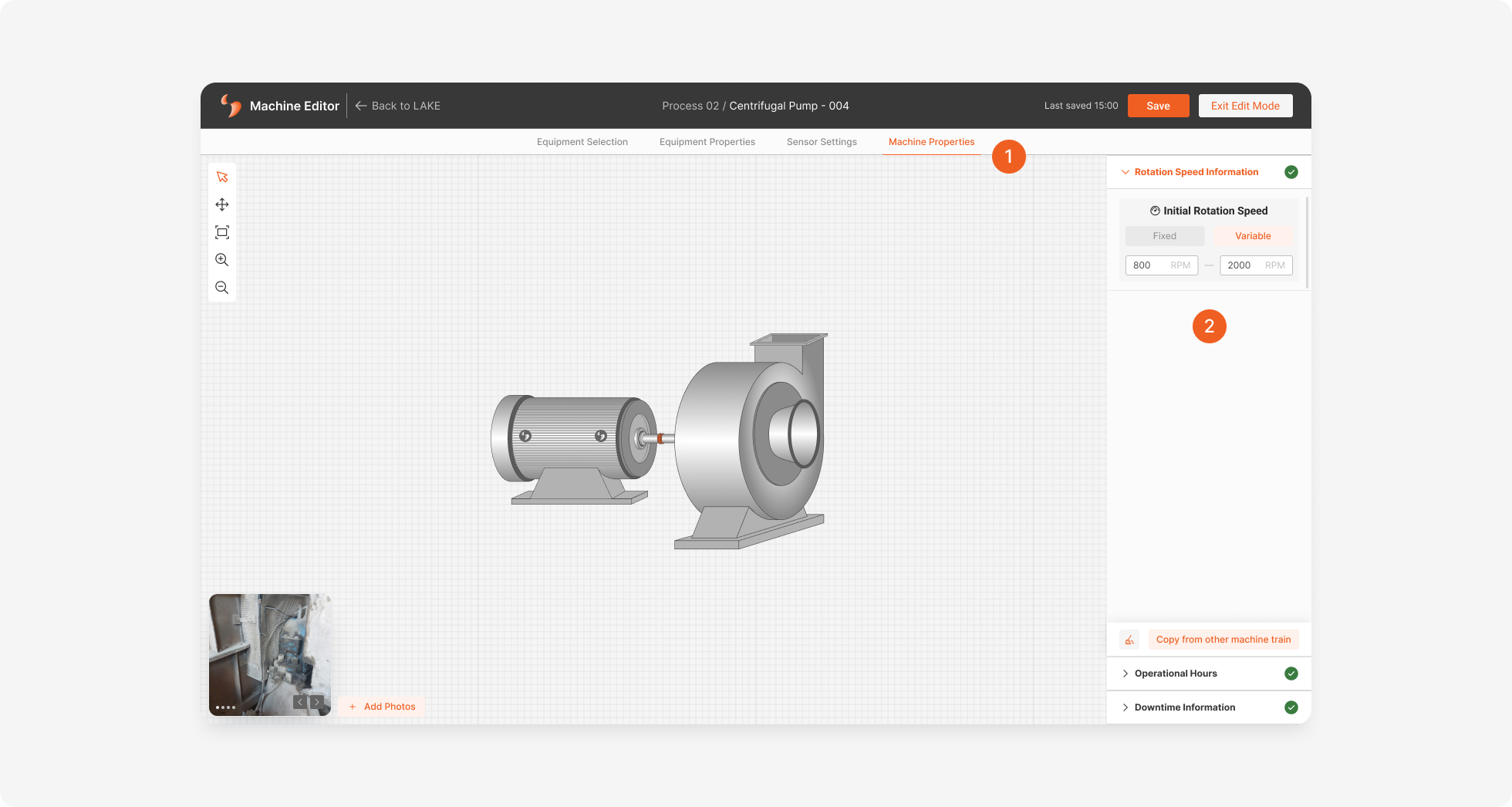

Machine Editor

Initial Rotation Speed

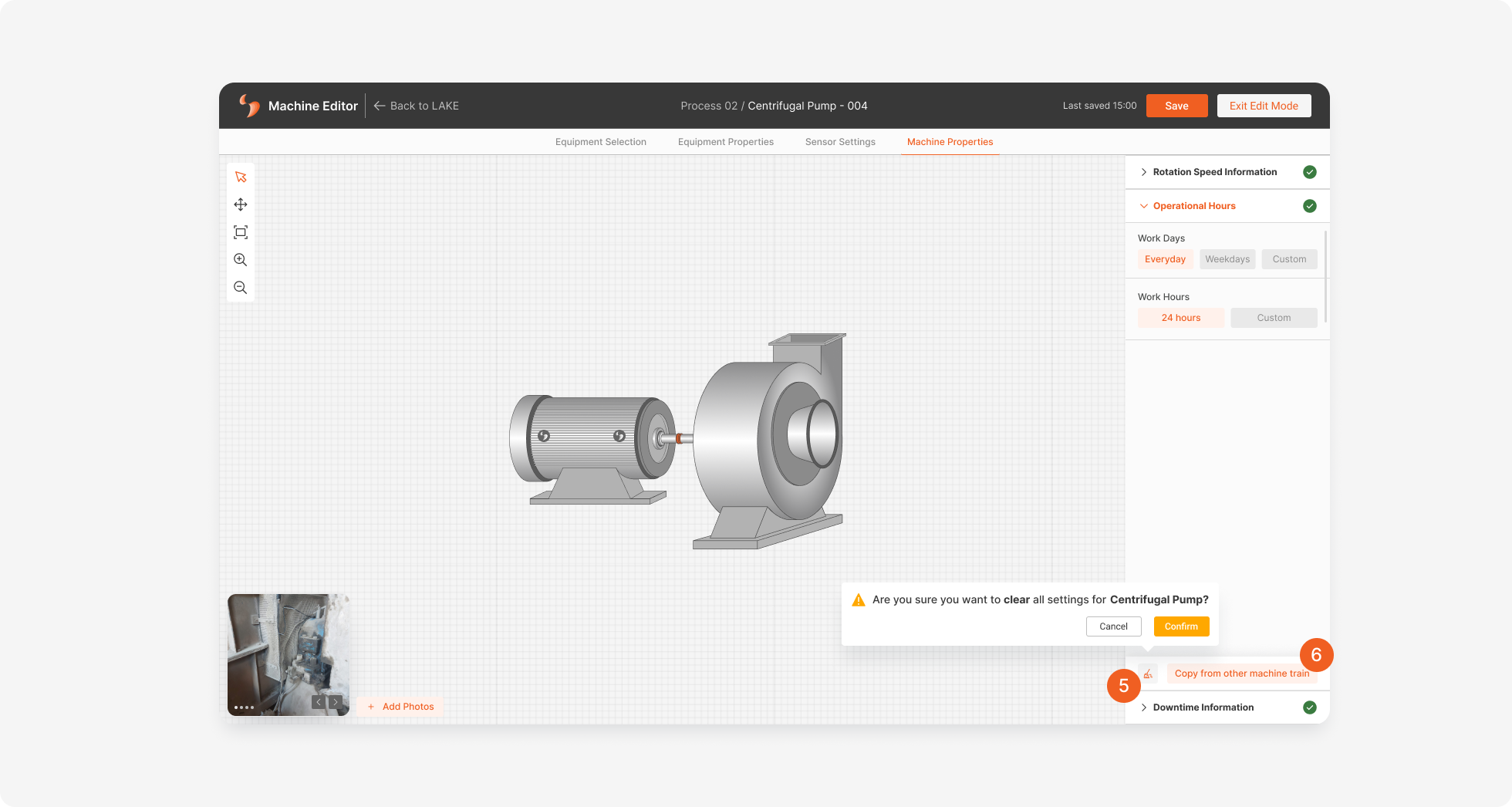

When you click on the Machine Properties tab added next to the Sensor Settings tab (shown with the number 1) in the Machine Editor, 3 separate fields appear on the right panel (shown with 2). The first property is the field where the rotation speed information of the machine is entered. If there is a driver equipment in the machine, it works synchronously with the RPM information received from the equipment side. In such cases where there is no driver representation in the machine, the way to receive RPM information has been opened. In addition, the input field has been revised according to the fixed or variable speed status of the machine.

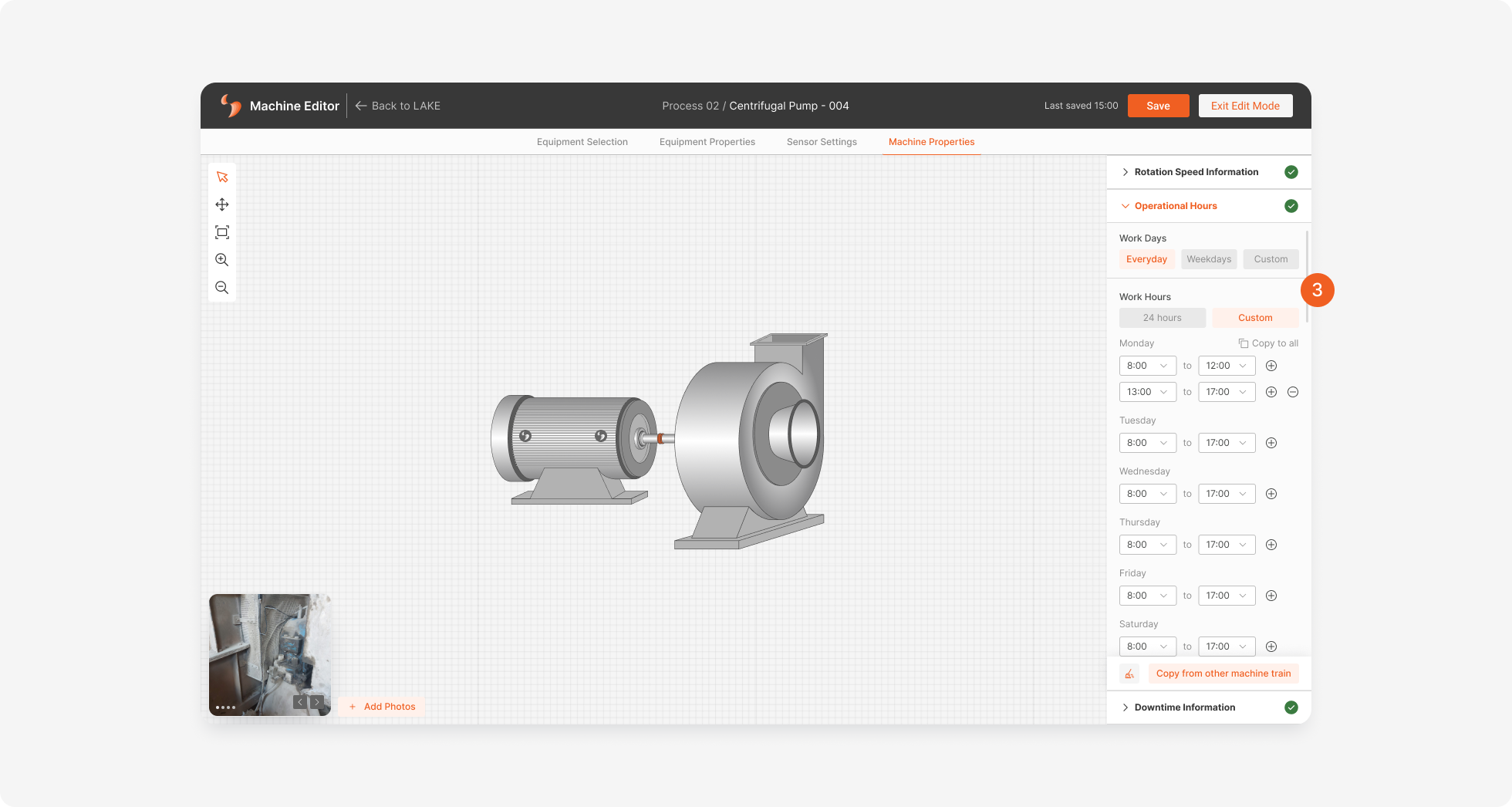

Operational Hours

The most critical situation in machine monitoring is the unplanned downtime of machines. To prevent this situation, we need the working hours of the machine. When the working hours are recorded in the system (shown with number 3) together with the speed (RPM) and stoppage time data obtained with the RPM Prediction Module in AI Studio, the system will send an occurance to the users when the machine stops unexpectedly. Thus, problems can be detected and intervened quickly without the need for continuous observation in the field.

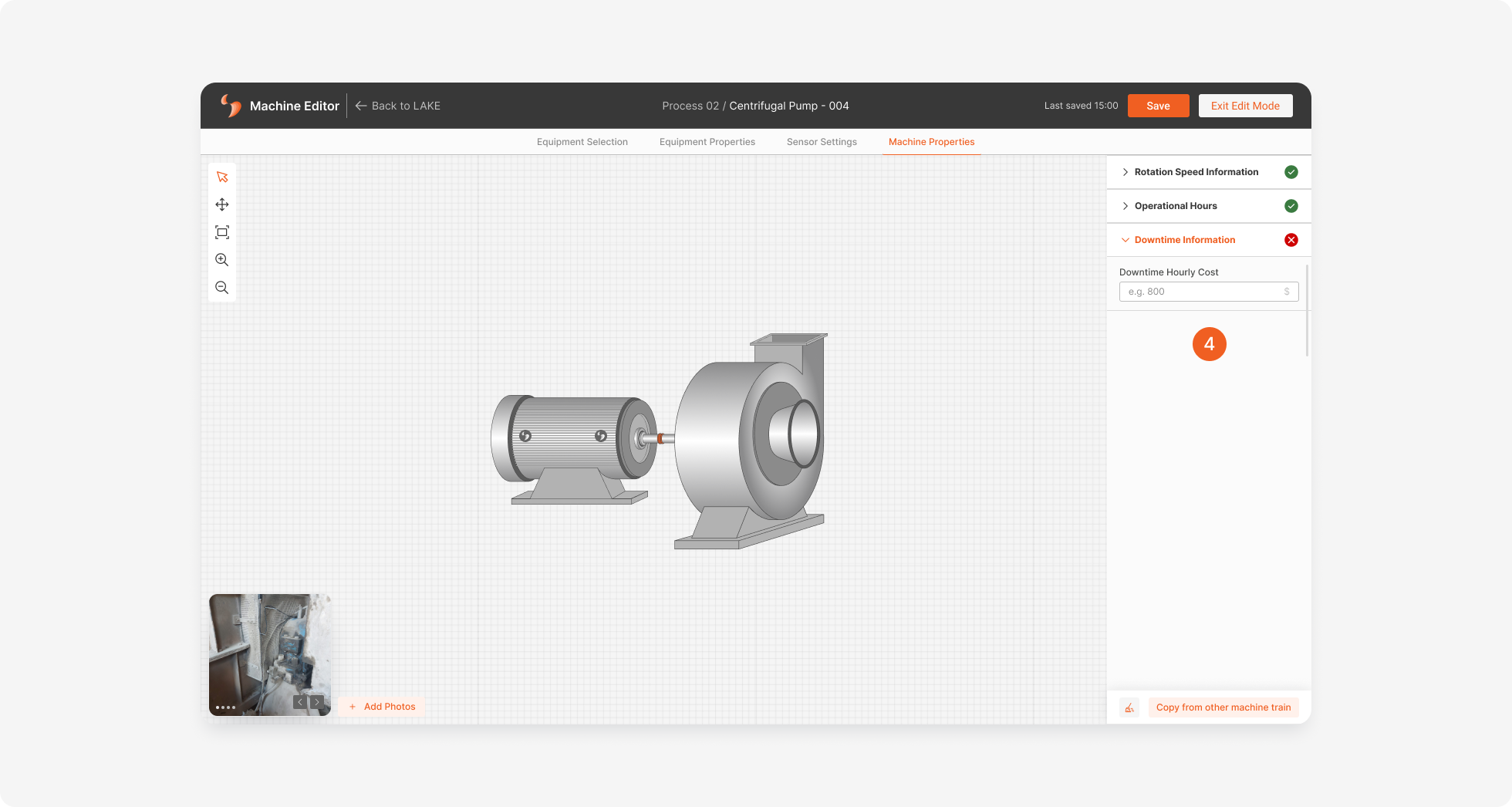

Downtime Information

As a result of unplanned downtime, facilities experience huge financial losses. By recording the cost of an hour of unplanned downtime in the system (shown with number 4), more accurate information about the annual costs of the machines can be obtained and more effective solutions can be produced to reduce costs.

Quick Actions

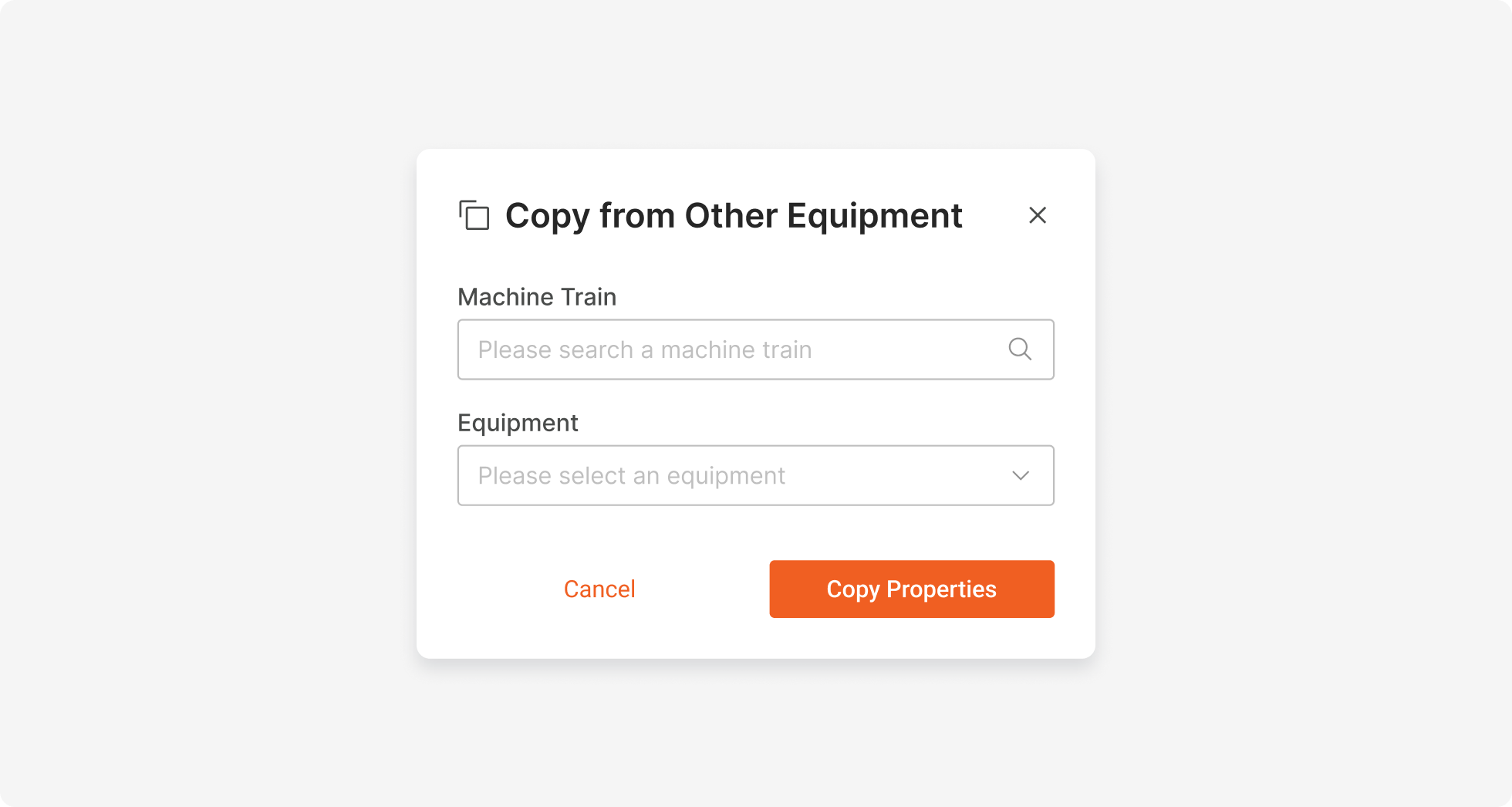

As in other sections of the editor, the information entered in each property panel can be easily reset (shown with number 5) or quickly copied from another machine train (shown with number 6).

Signal Toolbox

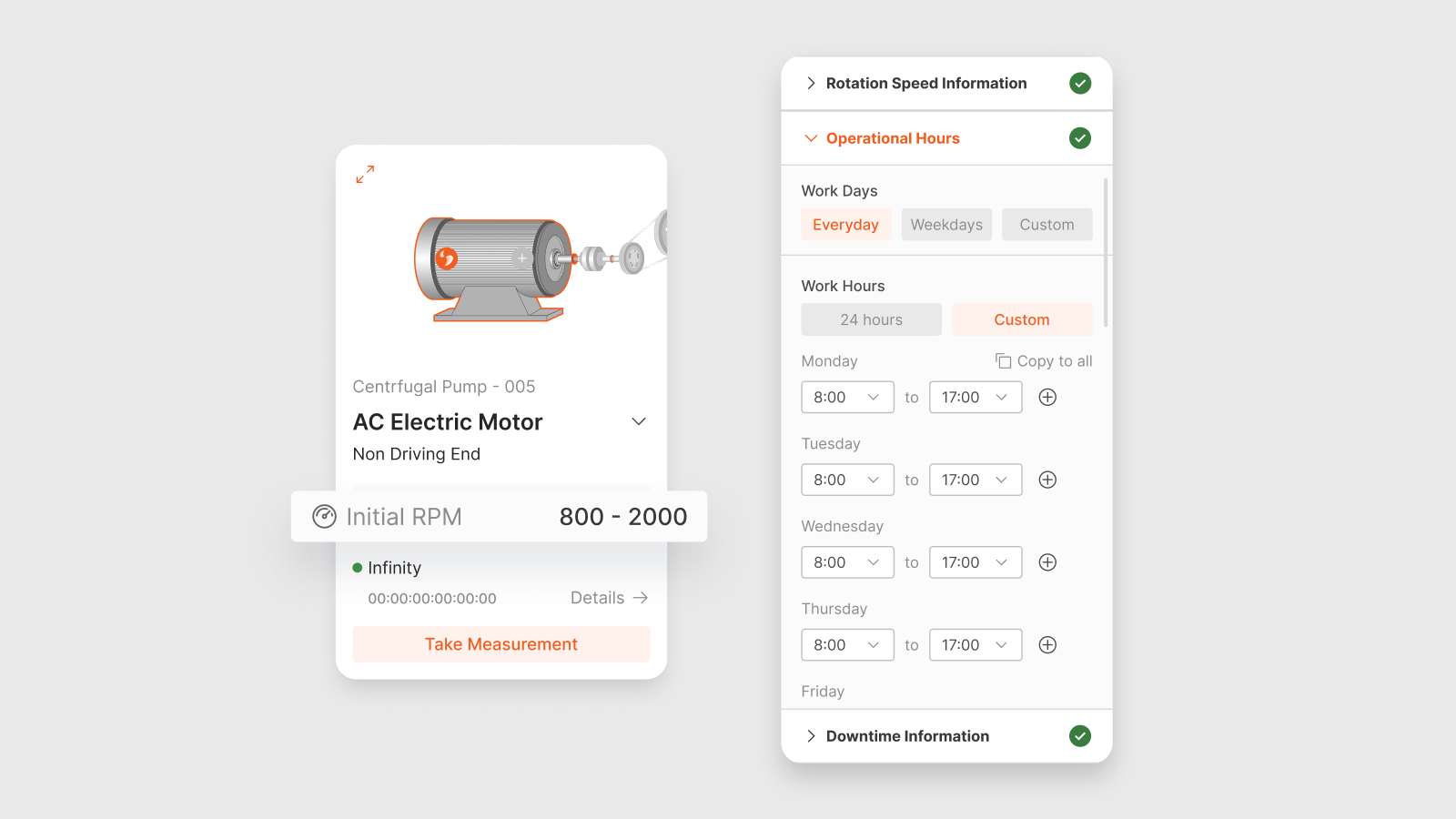

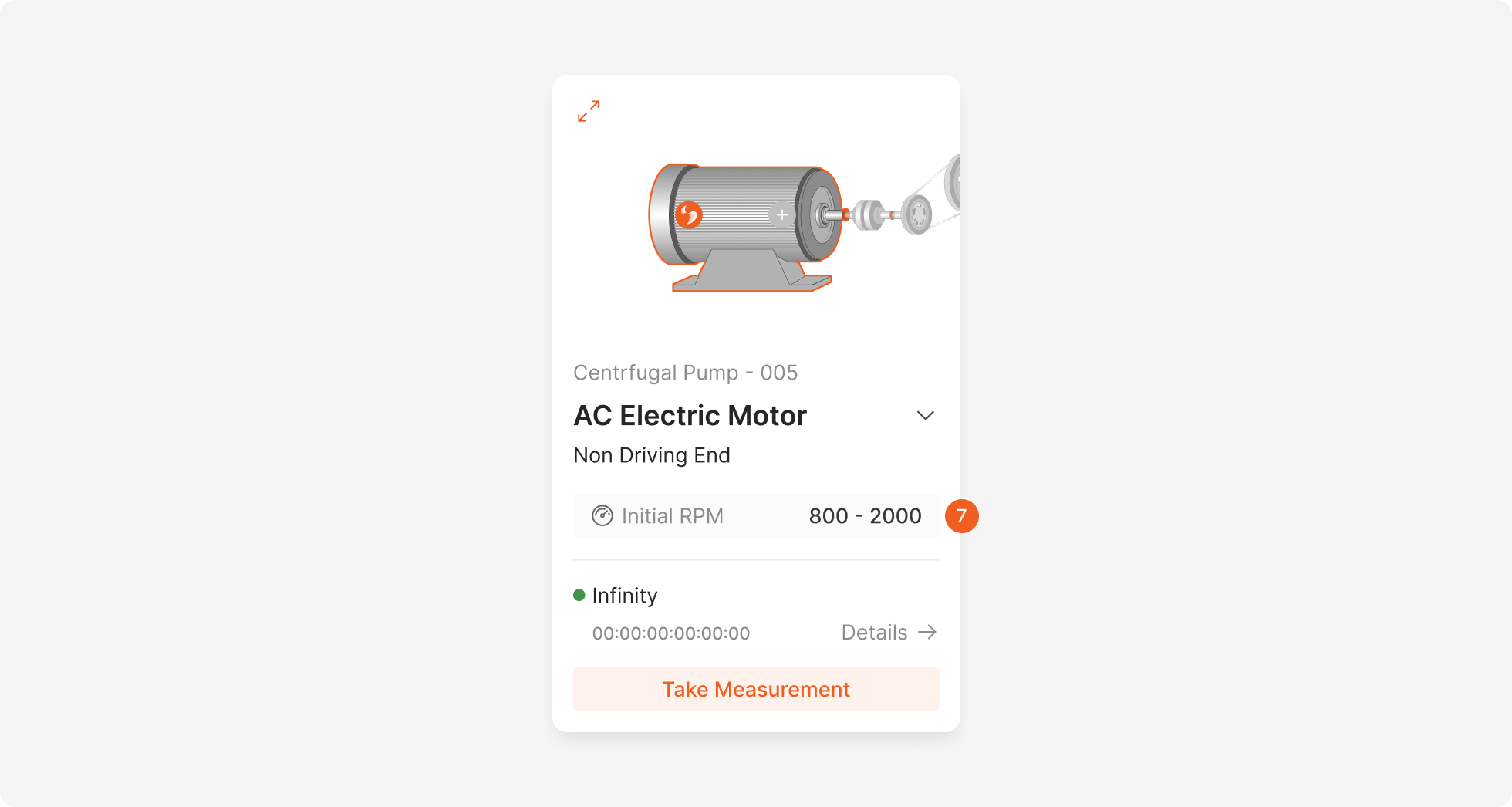

Initial Rotation Speed Information Section

The Initial RPM Information entered in the machine properties field has been added to the equipment selection wizard, making it easily accessible to users during data analysis, especially on the Signal Toolbox screen.

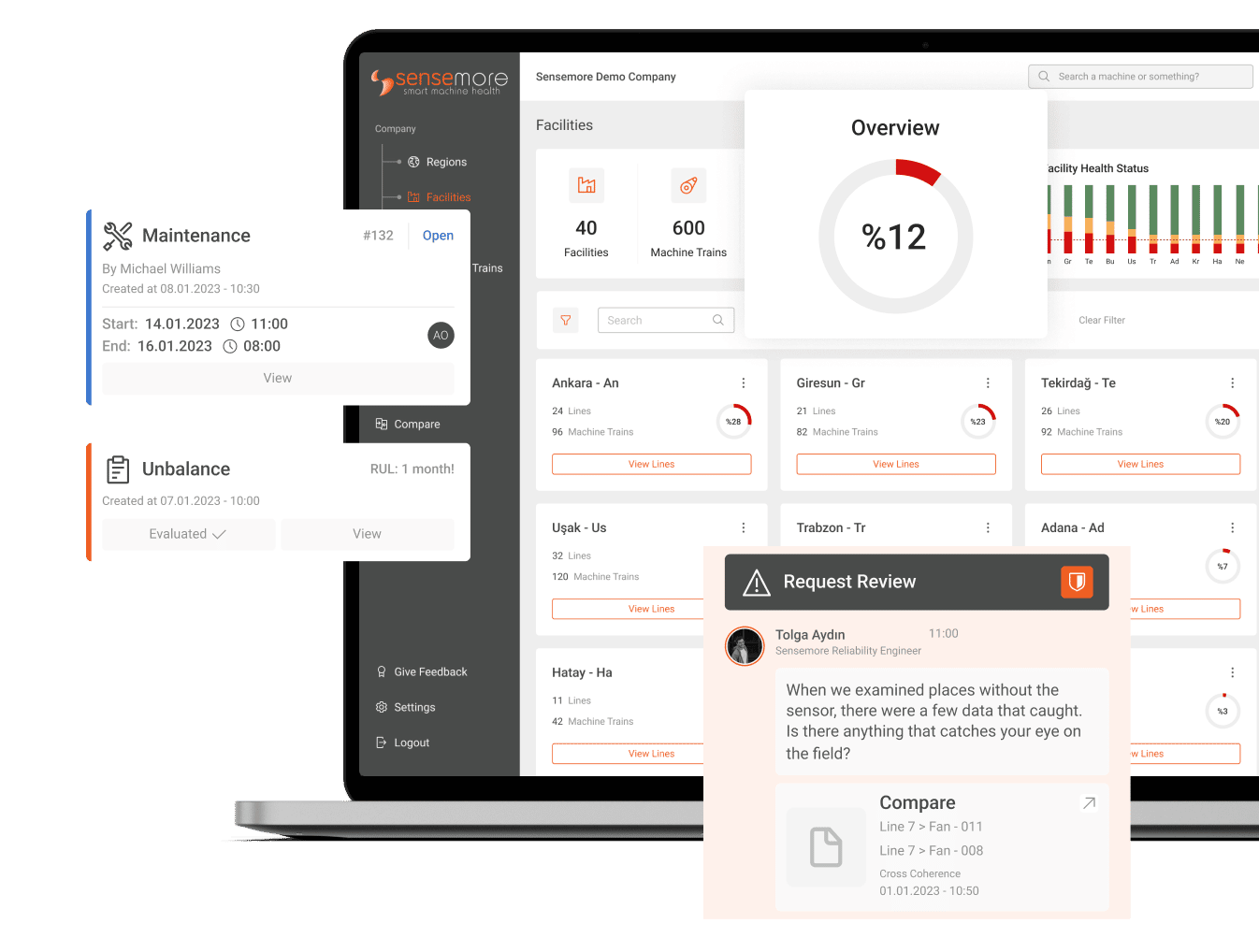

Discover Our Platform: LAKE

Sensemore LAKE is the reliability-focused data-driven machine health platform that offers users to create a digital maintenance culture to increase overall efficiency.