The Key to Success in the Iron and Steel Industry: Reliable Equipments

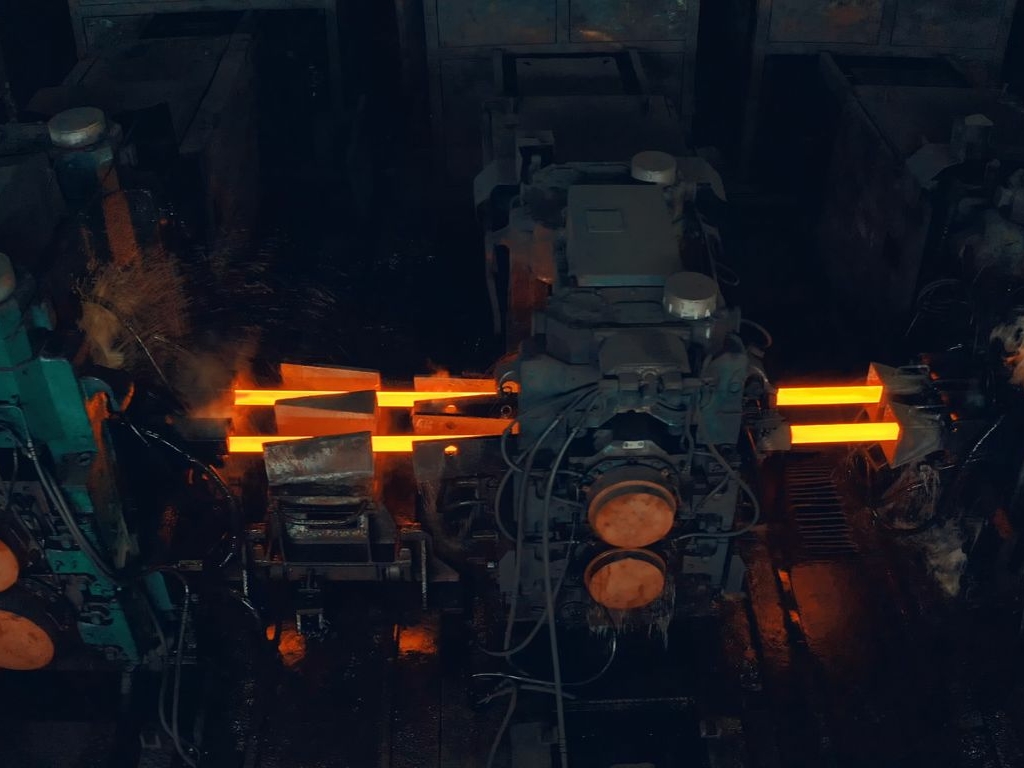

Plan maintenance before air blowers, cranes, rolling mills, and other machinery fail. Sensemore’s proactive approach reduces downtime, carbon emission and ensure that your crucial equipment is available when needed in the fast-paced iron and steel industry.

- Furnaces

- Rolling Mills

- Power Generation Equipment

- Compressors

- Pumps

- Forging Press

- Cutting Equipment

- Cranes & Material Handling Equipment

- Fans

- Lime Kiln

The iron & steel industry is the most responsible industrial sector with 30% of the CO2 emissions generated by the energy consumption from the industry.

Condition-Based Maintenance: The Green Steel Revolution

We provide you more sustainable production processes by reducing unplanned downtimes, extending the life of equipments and improving overall efficiency in the industry with the highest energy consumption and 7% to 9% of the world’s carbon emission.

Create a Reliability Centered Maintenance Culture

Reliability Centered Maintenance (RCM) is an approach that aims to maximize the reliability and availability of equipment by identifying the functions that are critical to the operation of the system, and then developing and implementing a maintenance strategy to ensure that these functions are performed reliably. It helps in identifying and eliminating unnecessary maintenance tasks, thus improving efficiency and productivity.

CaseStudies

Get in touch

Got a question? We'd love to hear from you.

Please fill out the contact form below and we’ll get back to you in 24 hours or you can schedule a meeting with our experts now.