What is Planned Maintenance?

Planned maintenance is crucial for ensuring the reliability, efficiency, and safety of equipment and assets within an organization. By proactively scheduling maintenance activities, businesses can minimize unexpected breakdowns, optimize…

Maintenance Management - An Overview

Maintenance management encompasses the systematic planning, coordination, and execution of maintenance activities to ensure optimal performance, reliability, and longevity of assets within various industries. It is a strategic function…

What is Overall Equipment Effectiveness (OEE) ?

In manufacturing, one of the crucial metrics used in this pursuit is Overall Equipment Effectiveness (OEE). OEE serves as a comprehensive measure of equipment performance, providing insights into how well equipment is utilized, how…

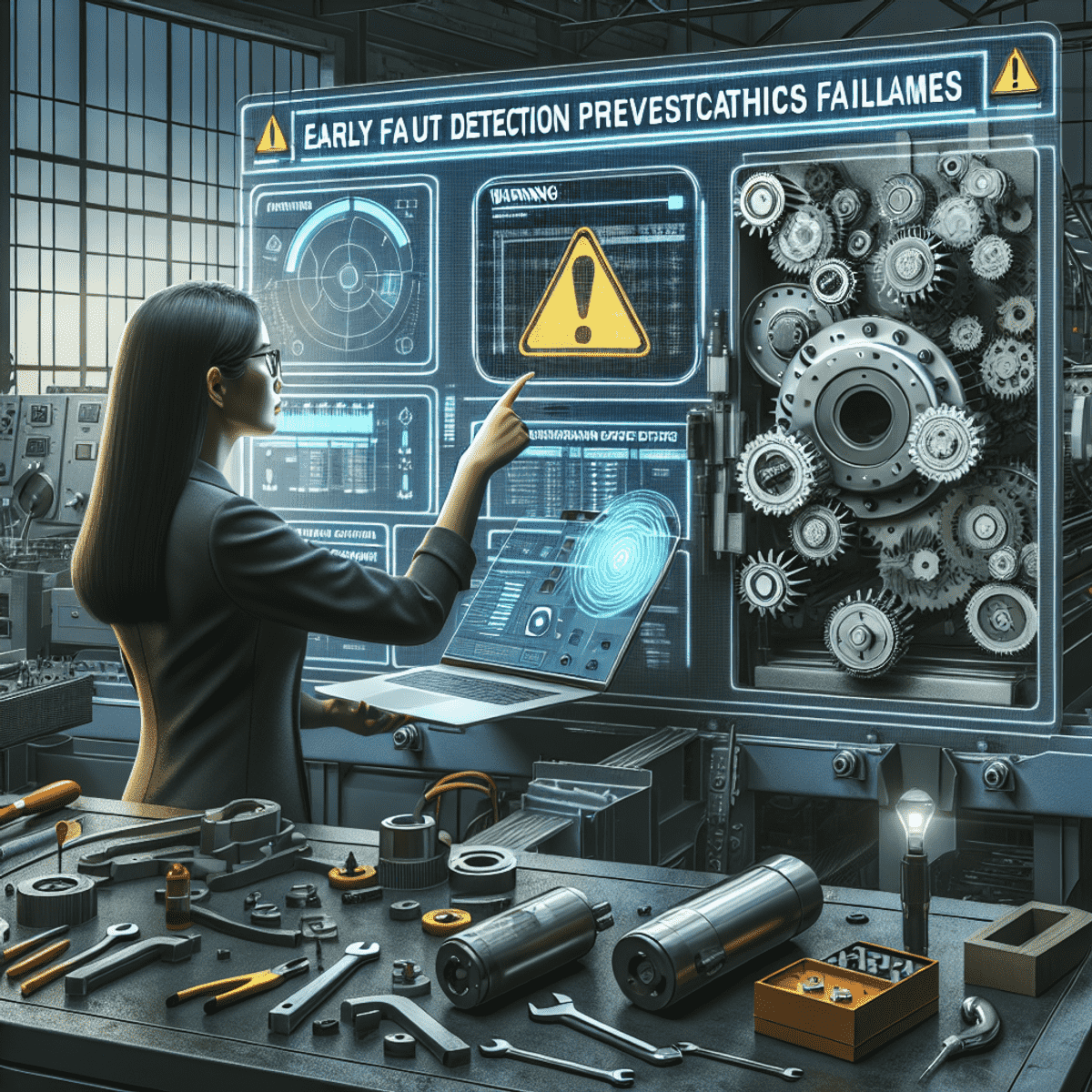

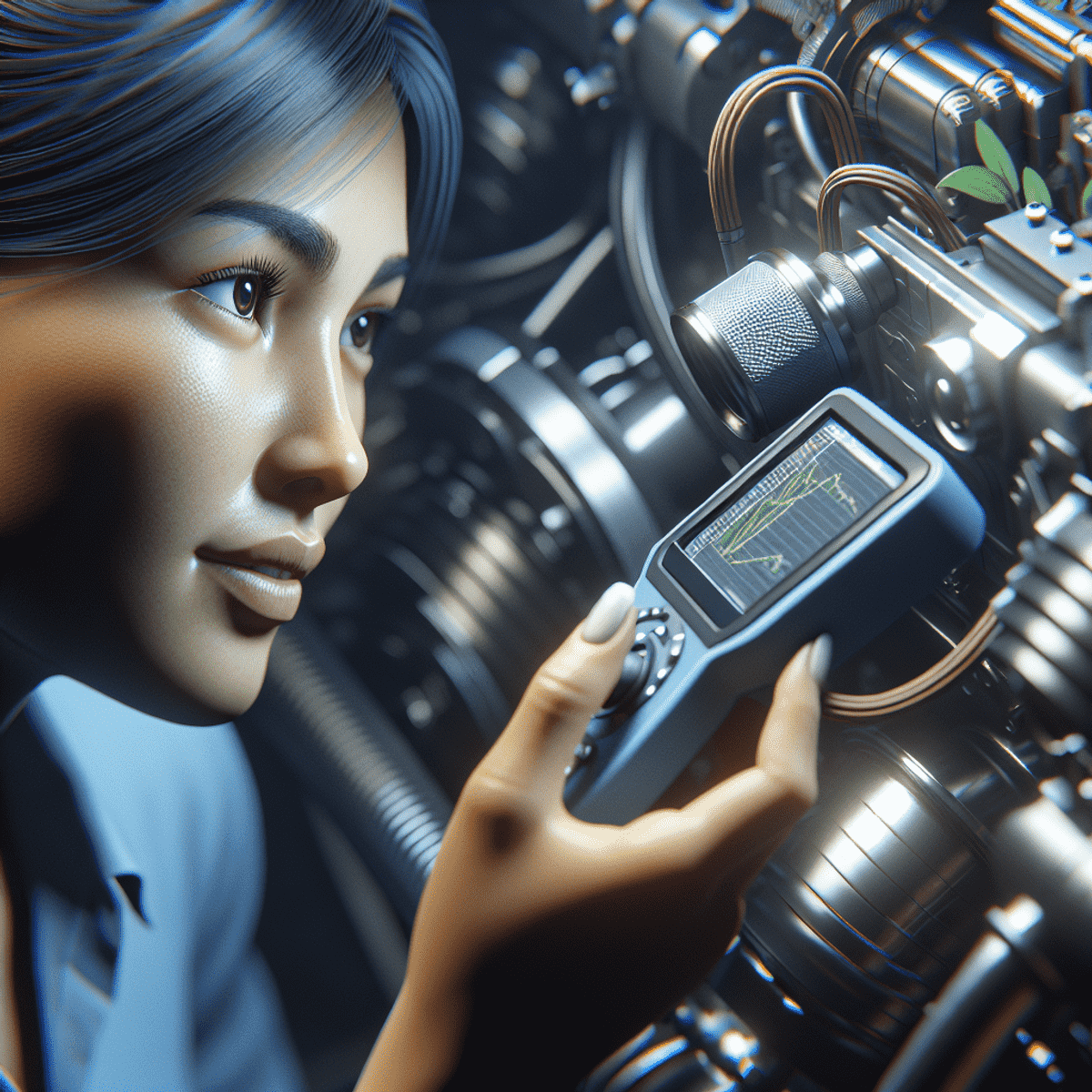

Preventing Catastrophic Failures through Early Fault Detection

Catastrophic failures not only disrupt productivity but also pose significant risks to personnel safety, environmental sustainability, and incur substantial financial losses for organizations. Industries are increasingly shifting from…

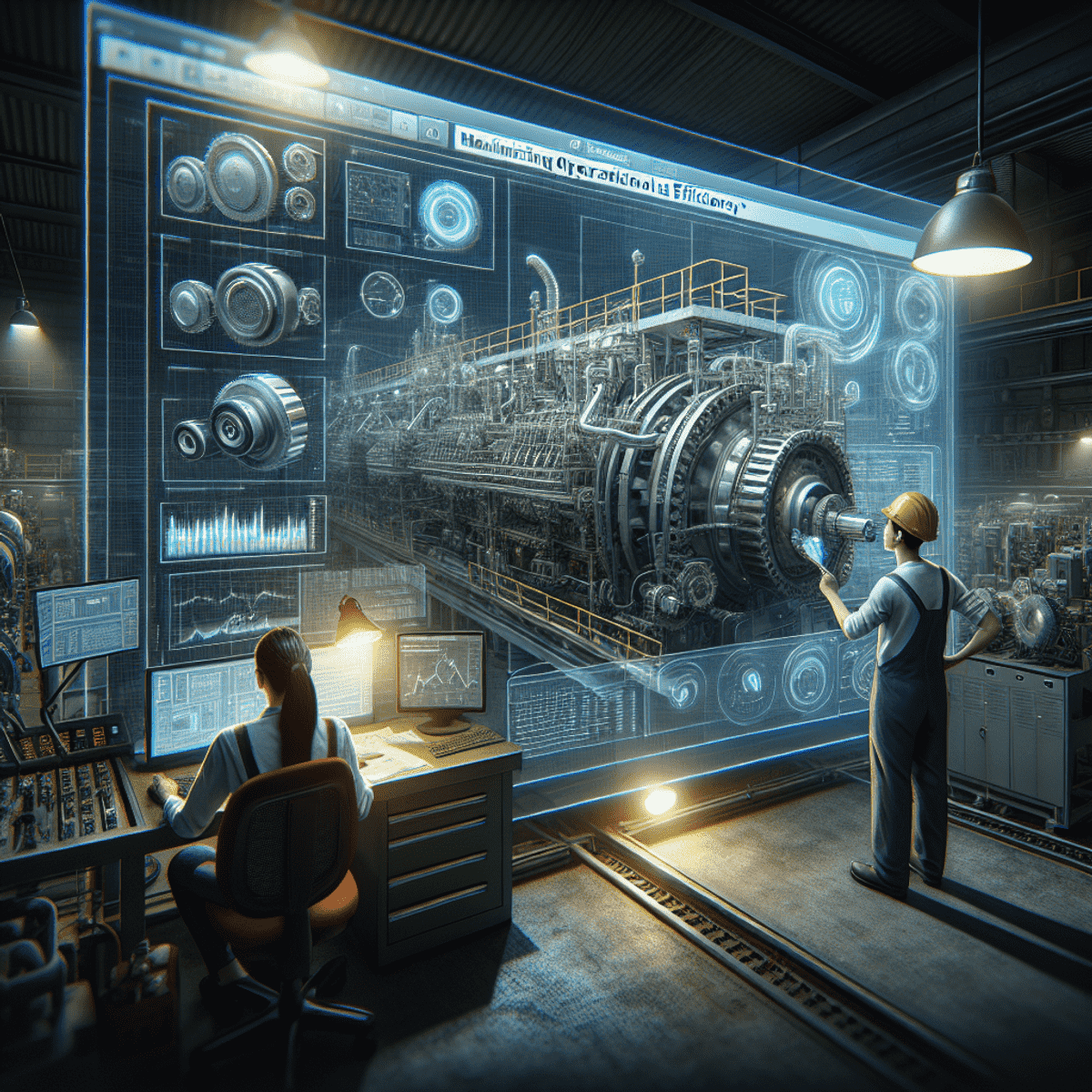

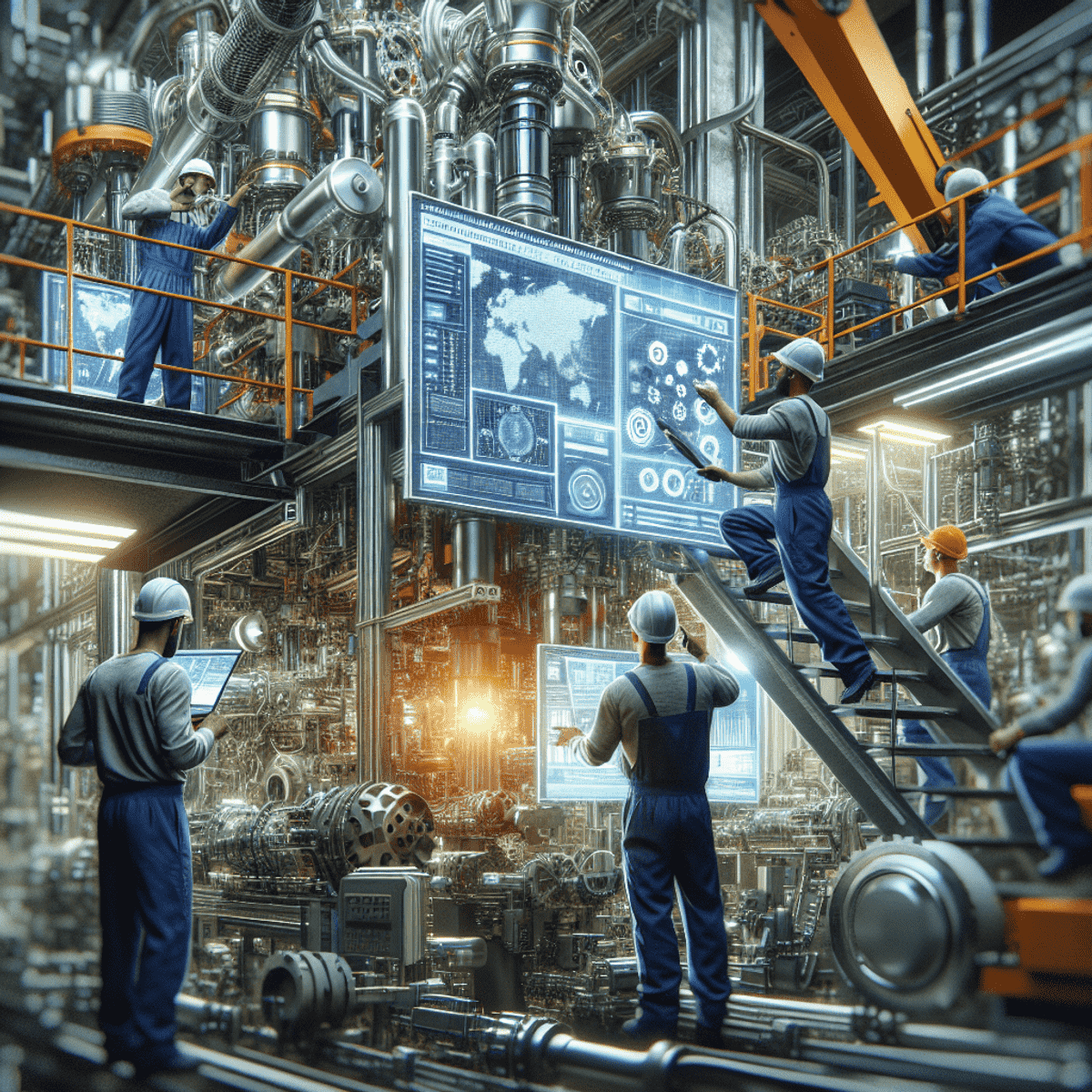

Maximizing Operational Efficiency with Predictive Maintenance

Operational efficiency stands as a cornerstone for success across diverse industries. It refers to the ability of a business or organization to utilize resources effectively in its operations to achieve maximum output with minimum input.…

Extending Asset Lifespan with Predictive Maintenance

Assets within industries are critical components of operations, serving as the backbone for productivity and revenue generation. The significance of extending asset lifespan cannot be overstated, as it directly impacts operational…

Cost Savings through Predictive Maintenance

The central focus of this article is to dive deeper into the cost-effectiveness and cost savings potential of predictive maintenance strategies within industrial contexts. While the benefits of predictive maintenance are widely…

Reducing Unplanned Downtime with Predictive Maintenance Solutions

Unplanned downtime stands as a critical concern for industries across various sectors, encompassing manufacturing, energy, transportation, and more. It refers to unexpected interruptions in production or operational processes due to…

Essential KPIs and Metrics for Maintenance Management

Key Performance Indicators (KPIs) and metrics for maintenance management are tools for assessing the effectiveness of maintenance management strategies. These measurable indicators provide valuable information about different aspects of…

Emerging Trends in Predictive Maintenance in 2024

Predictive maintenance (PdM) stands important for profit maximization and asset preservation. Unlike traditional reactive maintenance, PdM emphasizes pre-emptive actions, driven by real-time insights into equipment performance. The shift…