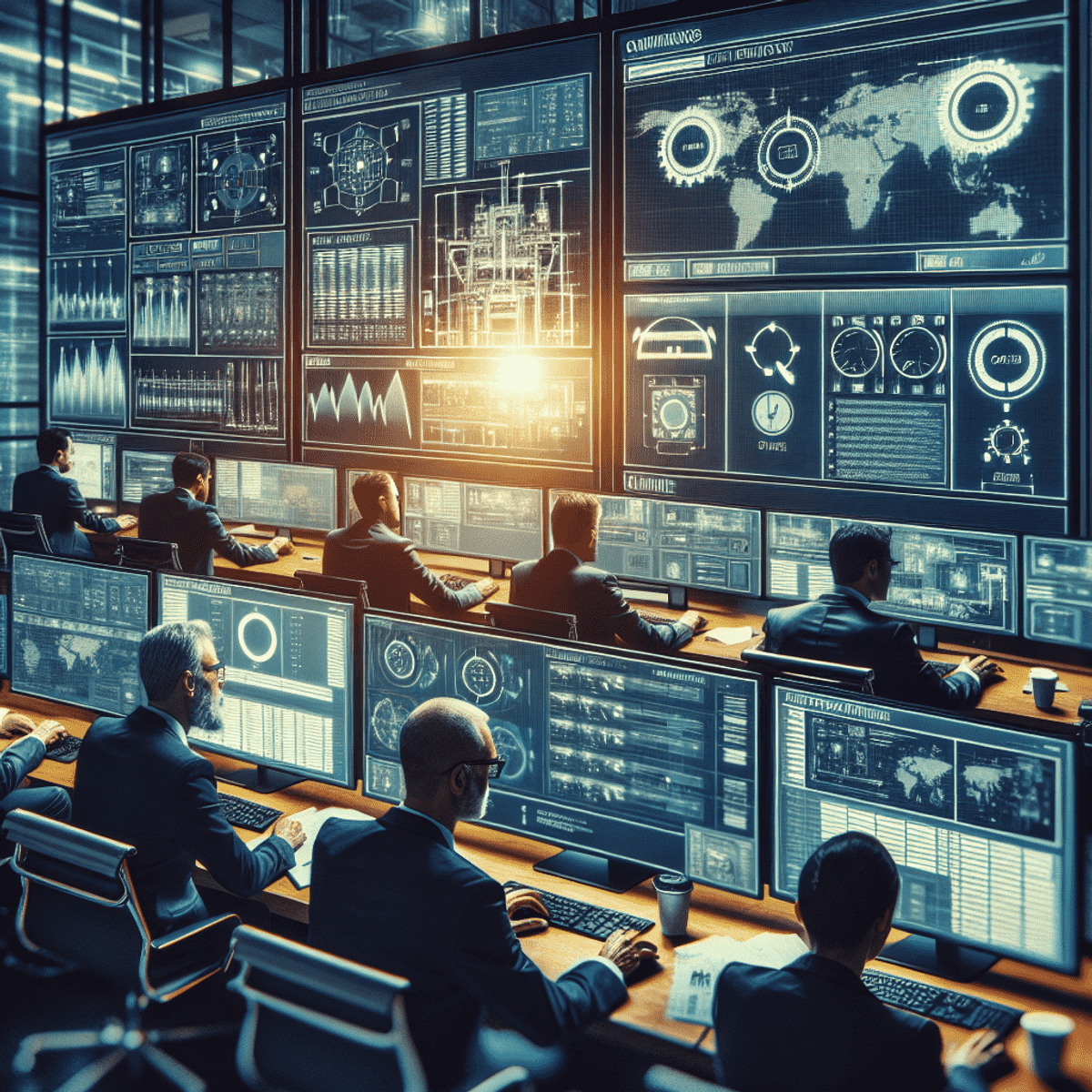

A Sneak Peak to the Future of Airport Operations: Predictive Maintenance in Airport Infrastructure

In today’s airport operations, operation teams face increasing pressure for smooth, reliable experiences for millions of passengers with an increasing demand day by day. From baggage handling systems to HVAC, elevators, and escalators,…

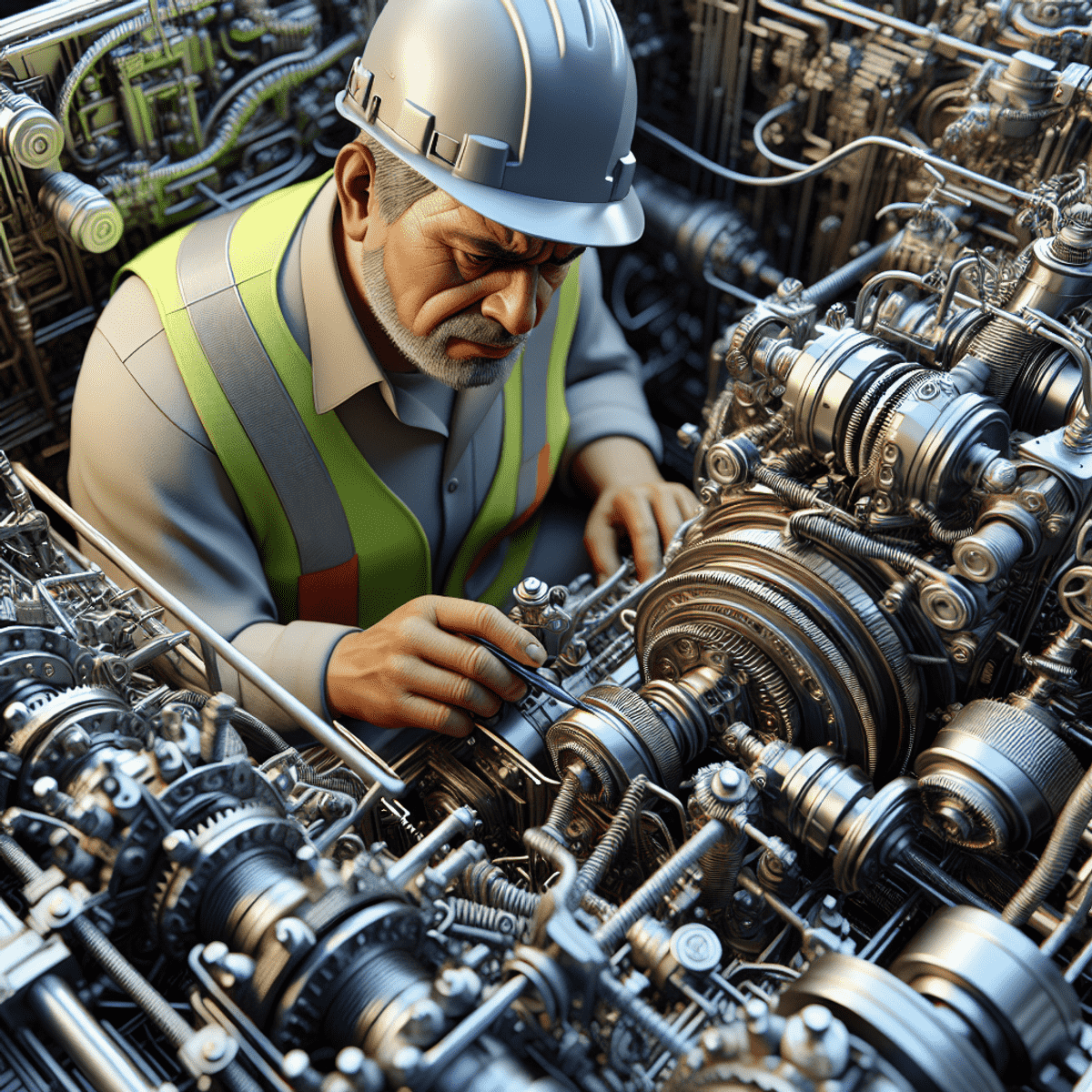

Maintenance Worker: Job Description, Skills, and Salary

Maintenance workers are essential personnel tasked with ensuring the smooth operation and safety of equipment and facilities. From inspecting machinery to performing repairs, they play a vital role in maintaining operational…

Maintenance Supervisor: Job Description Skills and Salary Range

Job Duties and Responsibilities Organizing Maintenance Operations Maintenance supervisors are integral to the smooth functioning of facilities, tasked with a myriad of responsibilities aimed at ensuring optimal performance and…

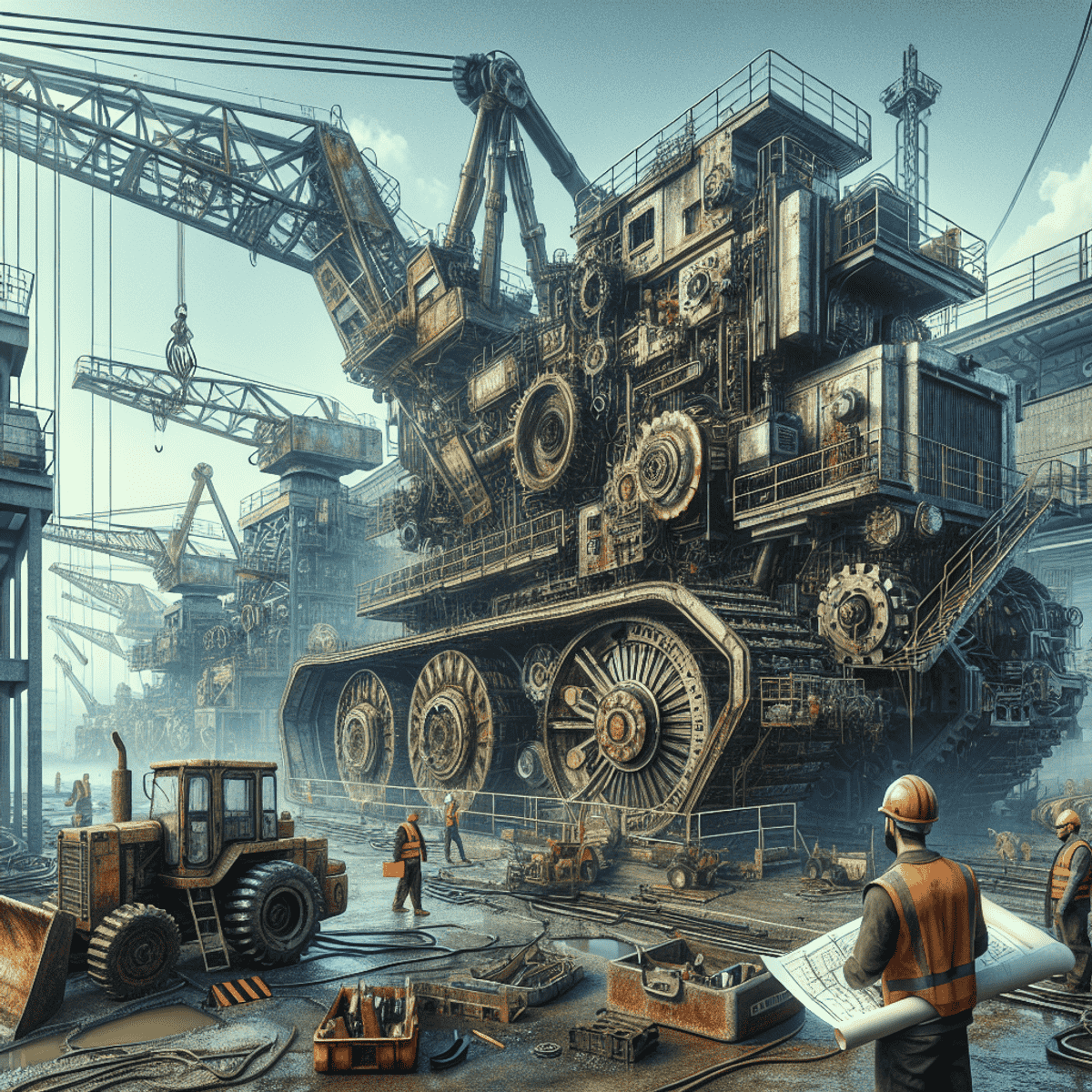

Unplanned Maintenance

Unplanned maintenance, akin to a stealthy saboteur, stealthily infiltrates the operational landscape, manifesting as the sudden, unforeseen failure of critical equipment or systems. It emerges with a swift and silent strike, catching even…

Exploring Equipment Failure Patterns

In the realm of industrial operations, ensuring the longevity and reliability of equipment is paramount. However, the journey towards achieving these objectives is fraught with challenges, chief among them being equipment…

Strategic Facility Asset Management: Planning Essentials

An asset management plan serves as the architectural blueprint for effectively stewarding a facility’s assets throughout their lifecycle to harmonize with organizational goals. It transcends mere enumeration,…

Machine Monitoring: Revolutionizing Manufacturing Efficiency

In the ever-evolving landscape of modern manufacturing, where precision, productivity, and profitability are paramount, the role of technology cannot be overstated. Amidst the intricate web of machinery and processes lies a…

How to Transfer Maintenance Knowledge Efficiently?

In today’s rapidly evolving industrial landscape, the imminent retirement of seasoned maintenance professionals poses a formidable challenge for organizations worldwide. As these experienced technicians exit the…

How to Develop an Effective Maintenance Policy

A maintenance policy serves as a comprehensive guideline for managing the upkeep of assets and equipment within an organization. It sets the framework for maintenance activities to ensure optimal performance, reliability, and…

5 Benefits of Lean Maintenance Programs

Lean maintenance programs have become increasingly popular among organizations seeking to optimize their maintenance processes and improve operational efficiency. By focusing on eliminating waste and continually…