Failure Codes: A Comprehensive Guide

In the intricate tapestry of maintenance and asset management, failure codes emerge as stalwarts of structured reporting, offering a systematic lens through which equipment failures are scrutinized. These concise…

Reactive Maintenance: A Risky Approach to Asset Management

Reactive maintenance is run-to-failure maintenance, a methodology where assets are allowed to operate until they encounter a breakdown, subsequently prompting repair or maintenance actions. While appearing straightforward,…

Replacement Asset Value (RAV)

Replacement Asset Value (RAV) is the monetary estimation of replacing assets currently undergoing maintenance activities. This article embarks on a comprehensive journey to unravel the complexities of RAV, exploring its…

FMECA for Maintenance

One method to achieve this is through Failure Mode and Effects Analysis (FMEA) and its extension, Failure Mode, Effects, and Criticality Analysis (FMECA). By systematically identifying potential failure modes and their effects before they…

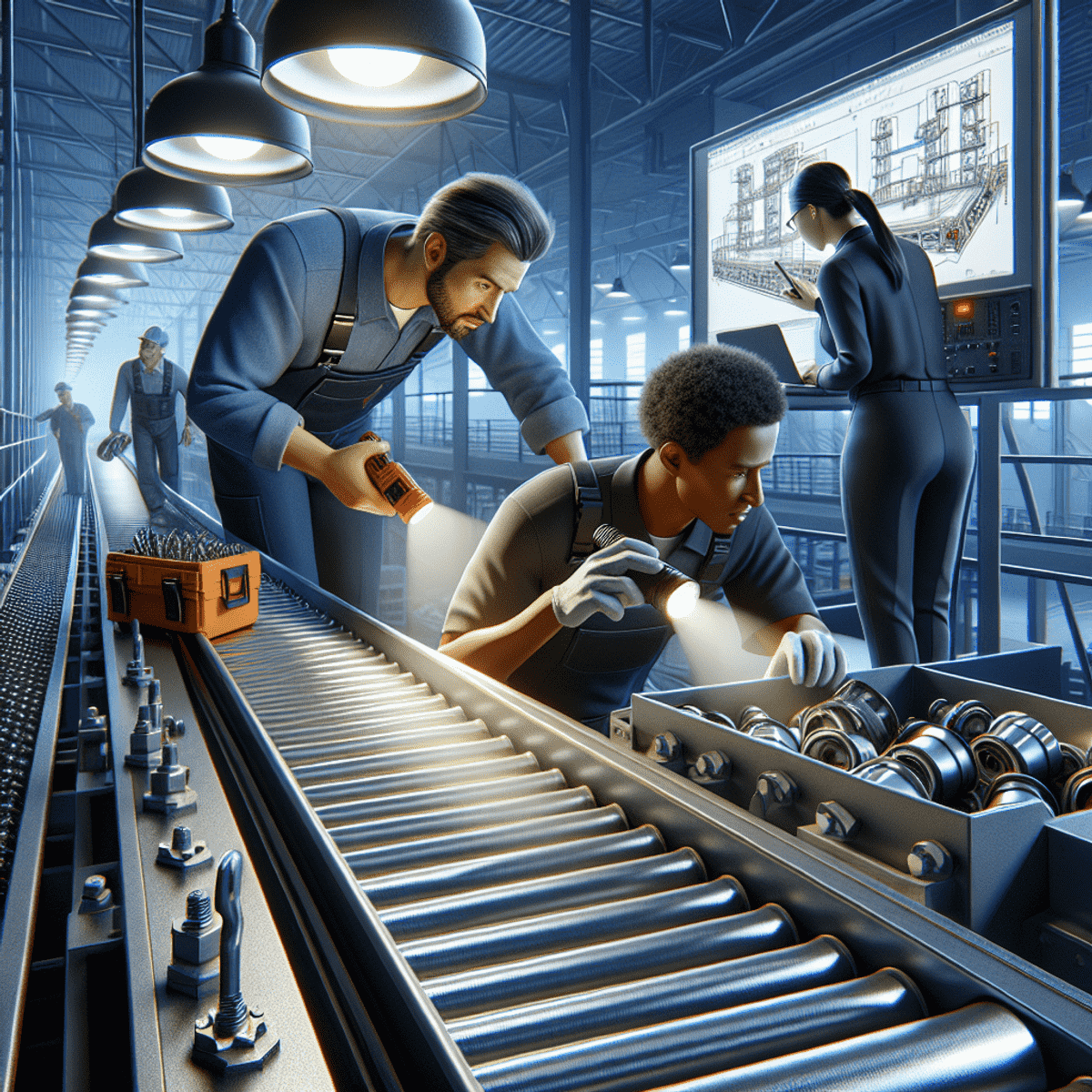

Conveyor Maintenance

Conveyors are vital components in various industries, facilitating the movement of materials efficiently and continuously. Regular maintenance is essential to prevent unexpected downtime, extend equipment lifespan, and improve operational…

Managing and Leading Effective Toolbox Conversations

Daily toolbox talks can significantly reduce incidents and injuries. Follow this guide to implement impactful toolbox talks at your workplace. Toolbox talks are short, daily safety meetings lasting typically 10-15 minutes. They are…

Improving Schedule Compliance for Maintenance Programs

In the dynamic landscape of maintenance management, where the smooth functioning of industrial operations hinges on the reliability of equipment and machinery, schedule compliance emerges as a pivotal determinant of success.…

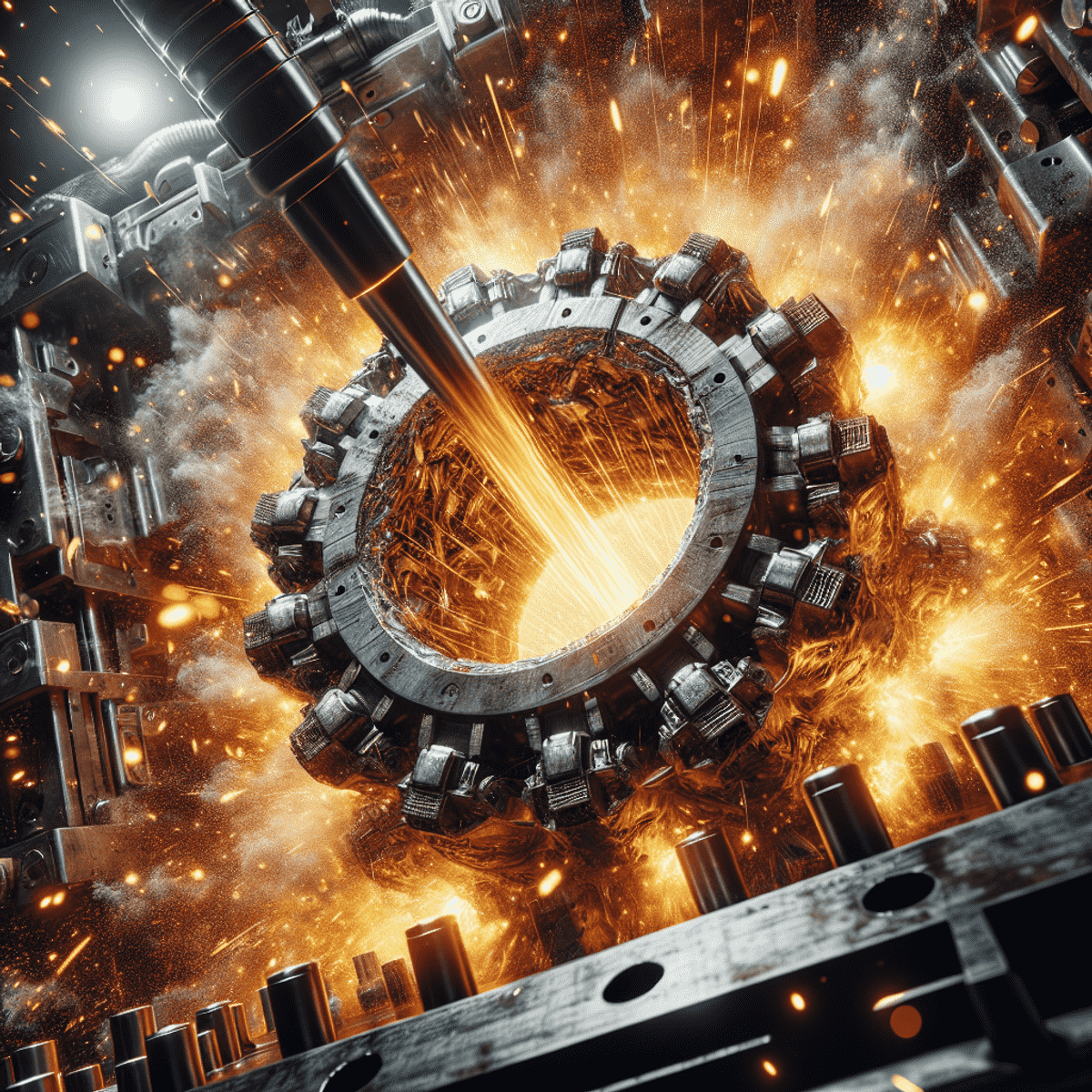

Understanding Destructive Testing and Its Applications

Destructive testing is invaluable insight into the durability, reliability, and performance of various materials and components. Despite its inherent nature of causing irreversible damage to the test specimens, the knowledge garnered…

CMMS vs CAFM: Key Differences

Computerized Maintenance Management System (CMMS) and Computer-Aided Facility Management (CAFM) systems both offer solutions for optimizing facility operations, they cater to distinct aspects of management. Common Use Cases and…

How To Properly Perform DFMEA & PFMEA

What is DFMEA and when is it used? DFMEA, or Design Failure Mode and Effects Analysis is a preemptive tool employed during the nascent stages of design to meticulously scrutinize and anticipate potential failure modes in a new product or…