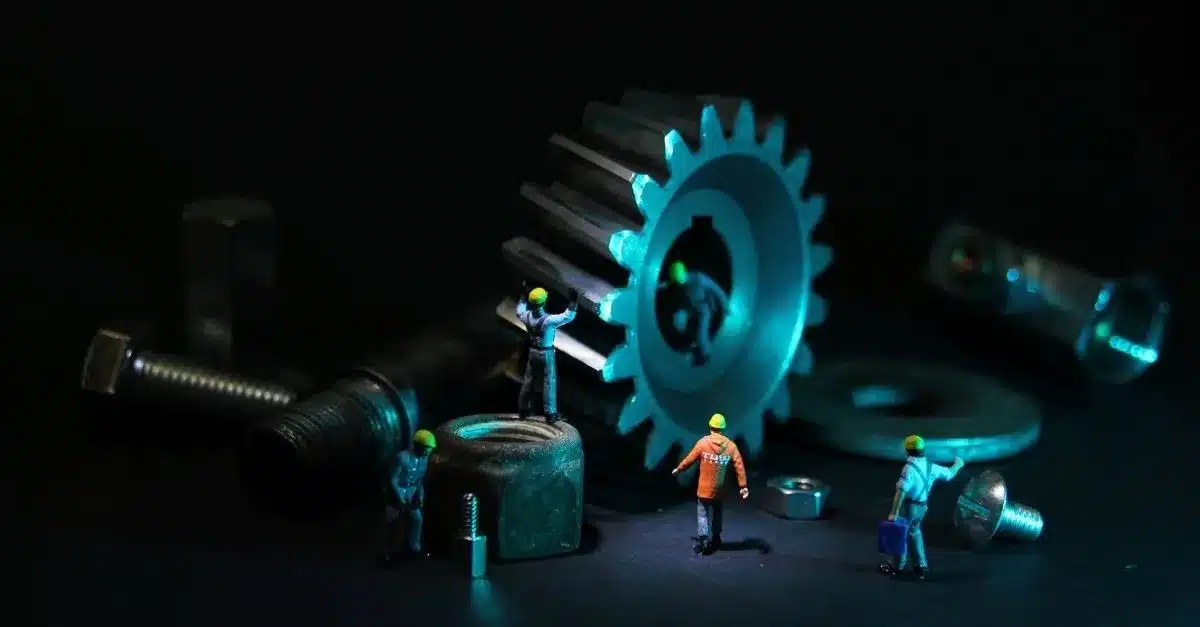

What is the Difference between Maintenance and Reliability?

Smooth functioning of equipment and systems brings us to two key concepts: maintenance and reliability. While these terms are often used interchangeably, they have distinct meanings and play unique roles in optimizing operations. By…

Ensuring Machine Reliability: The Role of Predictive Maintenance

Machine reliability holds importance in maintaining smooth operations and fueling business success. Whether it’s manufacturing, energy, transportation, or any other sector reliant on machinery, breakdowns and unplanned downtime can…

Preventive Maintenance Optimization: Enhancing Equipment Reliability

Preventive Maintenance Optimization (PMO) is a powerful methodology that combines predictive maintenance techniques with optimization strategies to revolutionize maintenance activities and significantly improve overall equipment…

What is Criticality Analysis and How to Do it

Criticality analysis is an important tool used in many industries to assess and prioritize assets based on their significance to operations and safety. This methodical approach helps identify critical assets that are crucial for…

Iron & Steel Industry and Predictive Maintenance Applications

The implementation of predictive maintenance strategies in the iron and steel industry has become a pivotal approach in ensuring the reliability and efficiency of operations. Leveraging advanced technologies, predictive maintenance has…

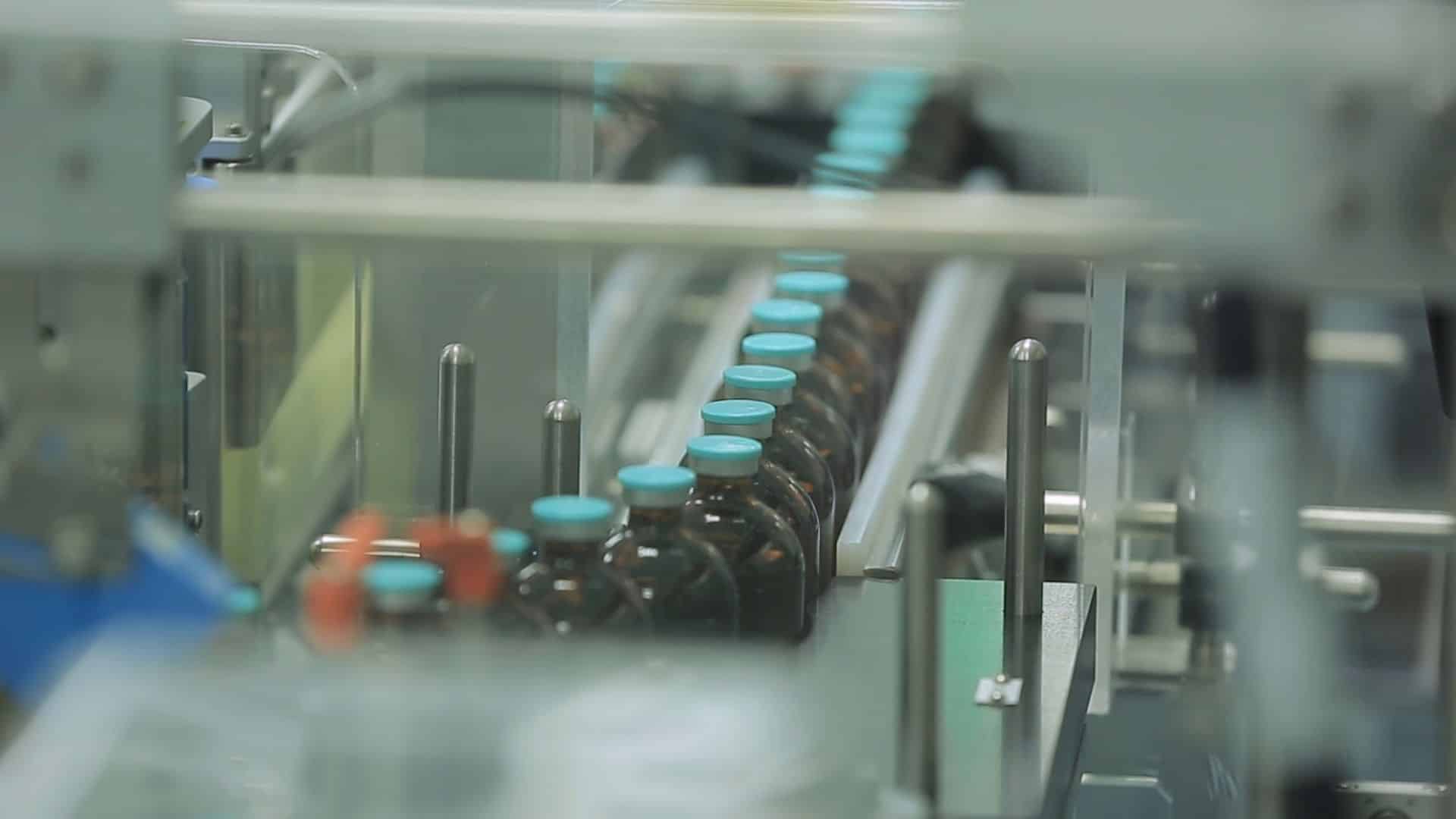

Pharmaceutical Industry and Predictive Maintenance Applications

Predictive maintenance is a proactive strategy crucial in the pharmaceutical industry, renowned for its precision and compliance requirements. Unlike traditional approaches, predictive maintenance employs advanced technologies to predict…

History and Future of Maintenance Culture

Maintenance is a comprehensive concept encompassing tests, measurements, replacements, adjustments, and repairs aimed at enhancing overall system health. This blog explores the future of maintenance cultures. In the early stages,…

What is Fault Tree Analysis?

Fault Tree Analysis (FTA) is a systematic and graphical method used for analyzing and understanding the potential failure modes within a system. It provides a structured approach to assess the relationships between various events and their…

What is FMEA?

Failure Mode and Effects Analysis (FMEA) is a systematic, proactive approach for evaluating a process to identify where and how it might fail. It serves as a critical risk management tool across diverse sectors, aiding in the…