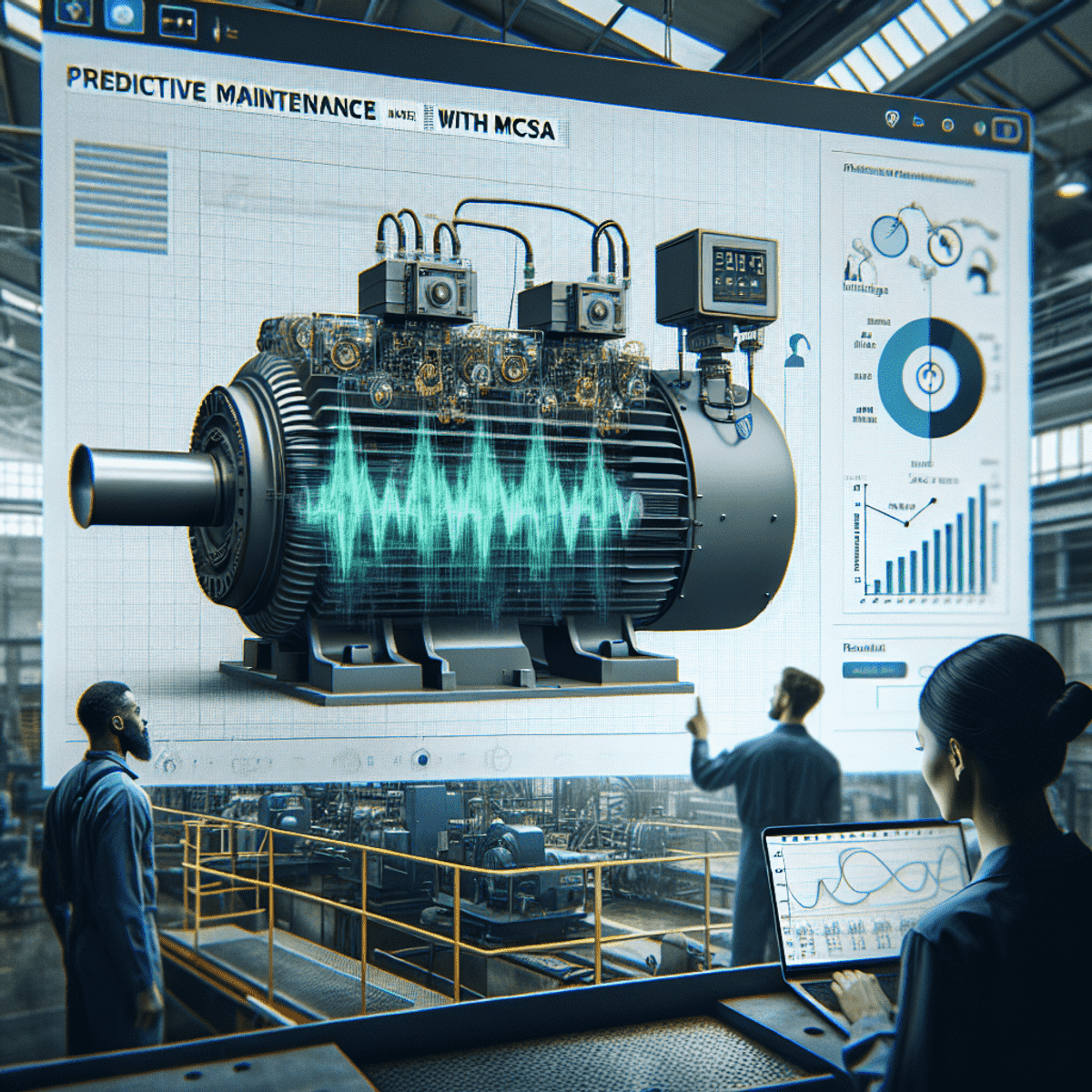

Motor Current Signature Analysis (MCSA) for Predictive Maintenance

Motor Current Signature Analysis (MCSA) technique serves as a sophisticated diagnostic tool, allowing engineers to delve deep into the heart of electrical machines and decode their operational health. MCSA operates as a methodical process…

Establishing a Predictive Maintenance Program Step-by-Step

Predictive maintenance involves using historical data, analytics, and cutting-edge technologies to anticipate potential equipment failures. Unlike reactive maintenance, where repairs occur after a breakdown, predictive maintenance allows…

Advantages and Benefits of Predictive Maintenance

The strategic implementation of Predictive Maintenance (PdM) has emerged as a game-changer. Leveraging advanced technologies, predictive maintenance allows for the continuous monitoring and prediction of equipment performance, paving the…

The Evolution of Maintenance Strategies

Maintenance has undergone significant evolution over the years. From the reactive approaches of the past to the proactive, data-driven strategies of today, this article delves into the transformative journey of maintenance strategies, the…

What is Predictive Maintenance?

Predictive Maintenance (PdM) stands at the forefront of modern industrial practices, revolutionizing the approach to equipment upkeep. This proactive maintenance strategy relies on data analysis to predict operational anomalies and…

The Evolution of Predictive Maintenance with Machine Learning and AI

The impact of unexpected equipment failures and the financial burden of costly downtime cannot be underestimated. These challenges have long been the bane of productivity and profitability. However, the evolution of predictive maintenance,…

Powerful Signal Analysis Tools for Vibration Analysis

In the landscape of mechanical engineering and industrial maintenance, the significance of predictive maintenance cannot be overstated. It stands as the linchpin in ensuring the operational reliability of machinery and equipment, thereby…

Navigating Machinery Vibration Analysis

Machinery vibration helps engineers and technicians assess the condition and performance of industrial equipment. This technique is not just a diagnostic tool; it’s a strategic asset that empowers professionals to understand the…

What is the Difference between Maintenance and Reliability?

Smooth functioning of equipment and systems brings us to two key concepts: maintenance and reliability. While these terms are often used interchangeably, they have distinct meanings and play unique roles in optimizing operations. By…

Ensuring Machine Reliability: The Role of Predictive Maintenance

Machine reliability holds importance in maintaining smooth operations and fueling business success. Whether it’s manufacturing, energy, transportation, or any other sector reliant on machinery, breakdowns and unplanned downtime can…