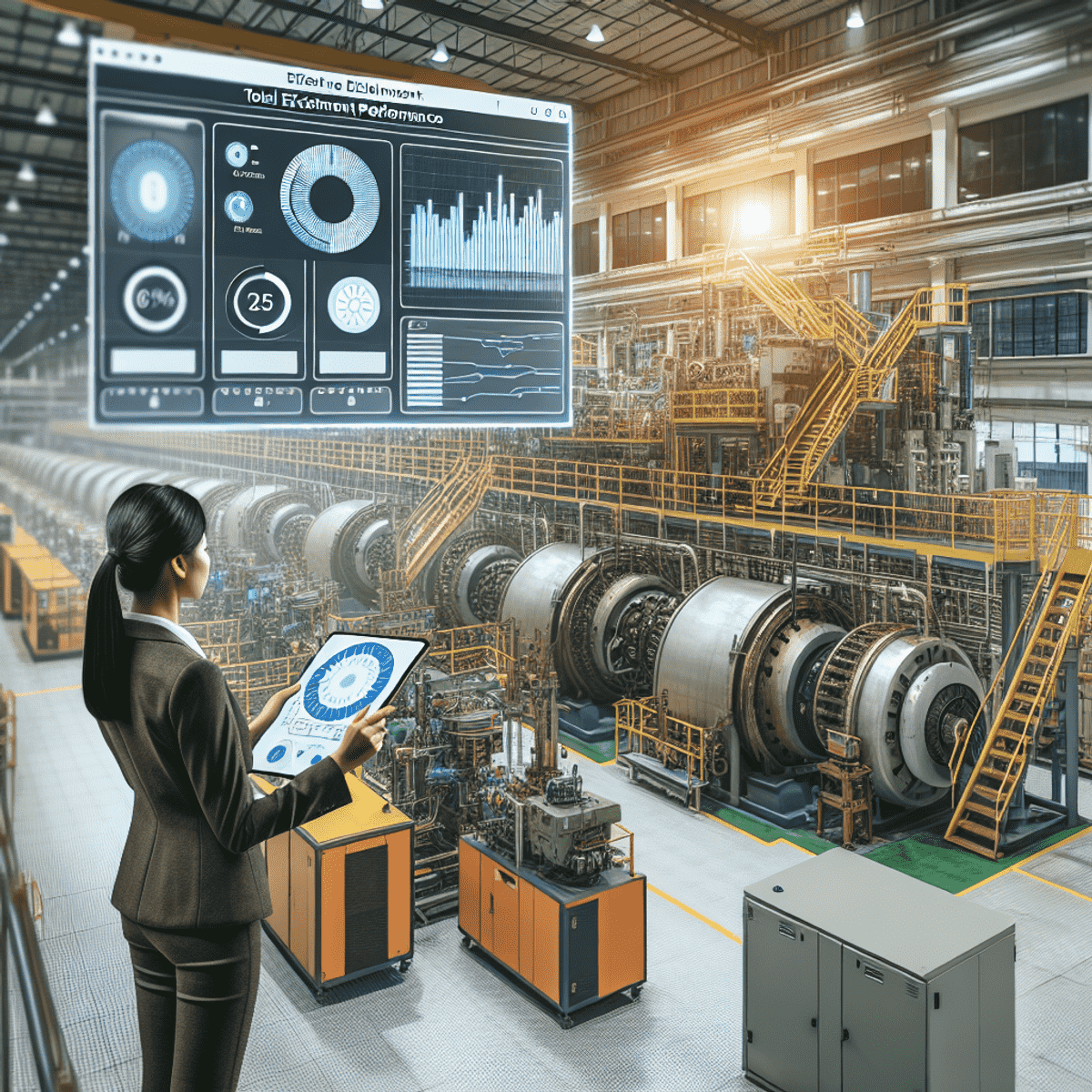

Total Effective Equipment Performance (TEEP)

TEEP considers all available productive time to provide management with a comprehensive view of manufacturing efficiency. Optimizing this key metric can drive major gains. Total Effective Equipment Performance (TEEP) is a measure, that…

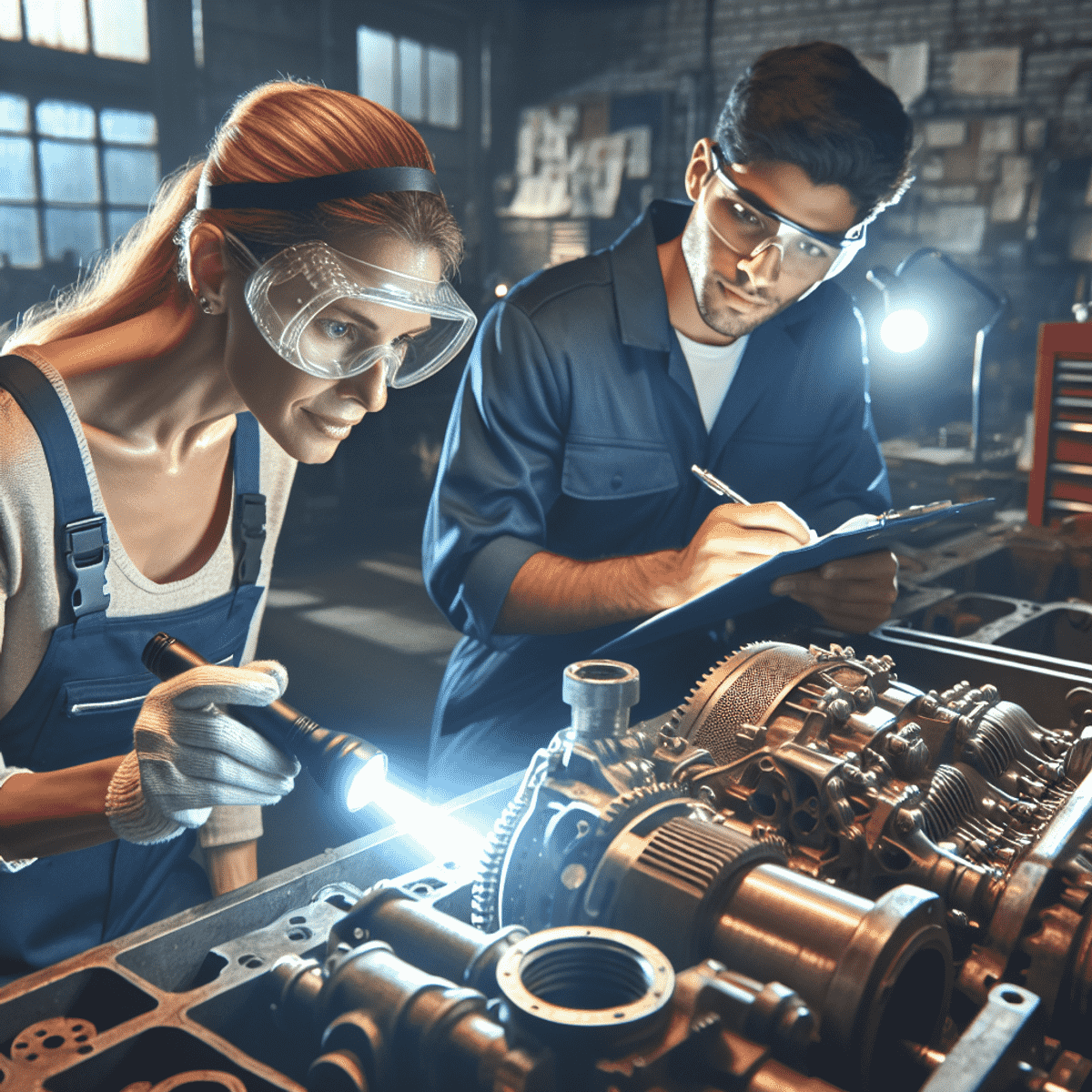

What Is Visual Inspection in Maintenance and Why Is It Used?

Visual inspection is a detailed examination of equipment, products, or processes using the human eye to detect flaws, defects, wear, or issues. Despite the increasing adoption of automated inspection systems, visual inspection remains…

The Costs and Causes of Idle Time

Idle time is wasted time that reduces productivity and profitability. Understanding what causes it and taking steps to reduce it can significantly improve operations. Idle time refers to periods when an asset like a machine or employee is…

What is Computerized Maintenance Management System (CMMS)?

A Computerized Maintenance Management System (CMMS) is a robust software solution designed to streamline maintenance operations, enhance asset management, and drive operational efficiency within organizations. By leveraging advanced…

MTTR: Understanding its Role in Asset Maintenance

MTTR, or Mean Time To Repair is a metric of asset maintenance that measures the average duration required to rectify equipment issues and restore them to operational status. This metric encapsulates various stages of the repair process,…

Improving First Time Fix Rate (FTFR)

First Time Fix Rate (FTFR) is a performance metric of maintenance and repair operations. A high FTFR not only denotes operational efficiency but also directly correlates with enhanced customer satisfaction and improved financial outcomes…

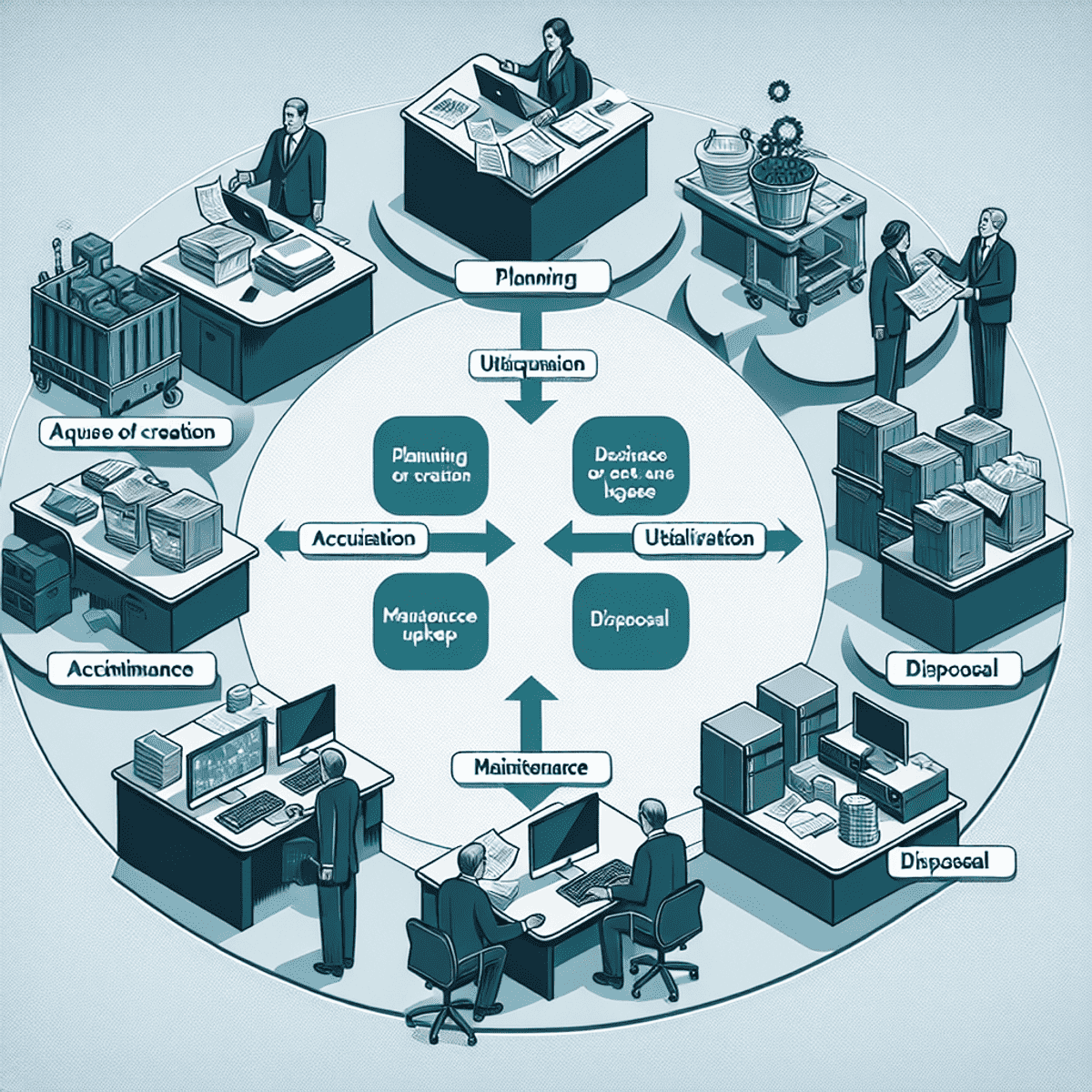

What is Asset Lifecycle? Step-by-Step

Organizations across industries rely on a diverse array of industrial assets to support their operations, ranging from machinery and equipment to infrastructure and facilities. The lifecycle of these assets encompasses a series of stages,…

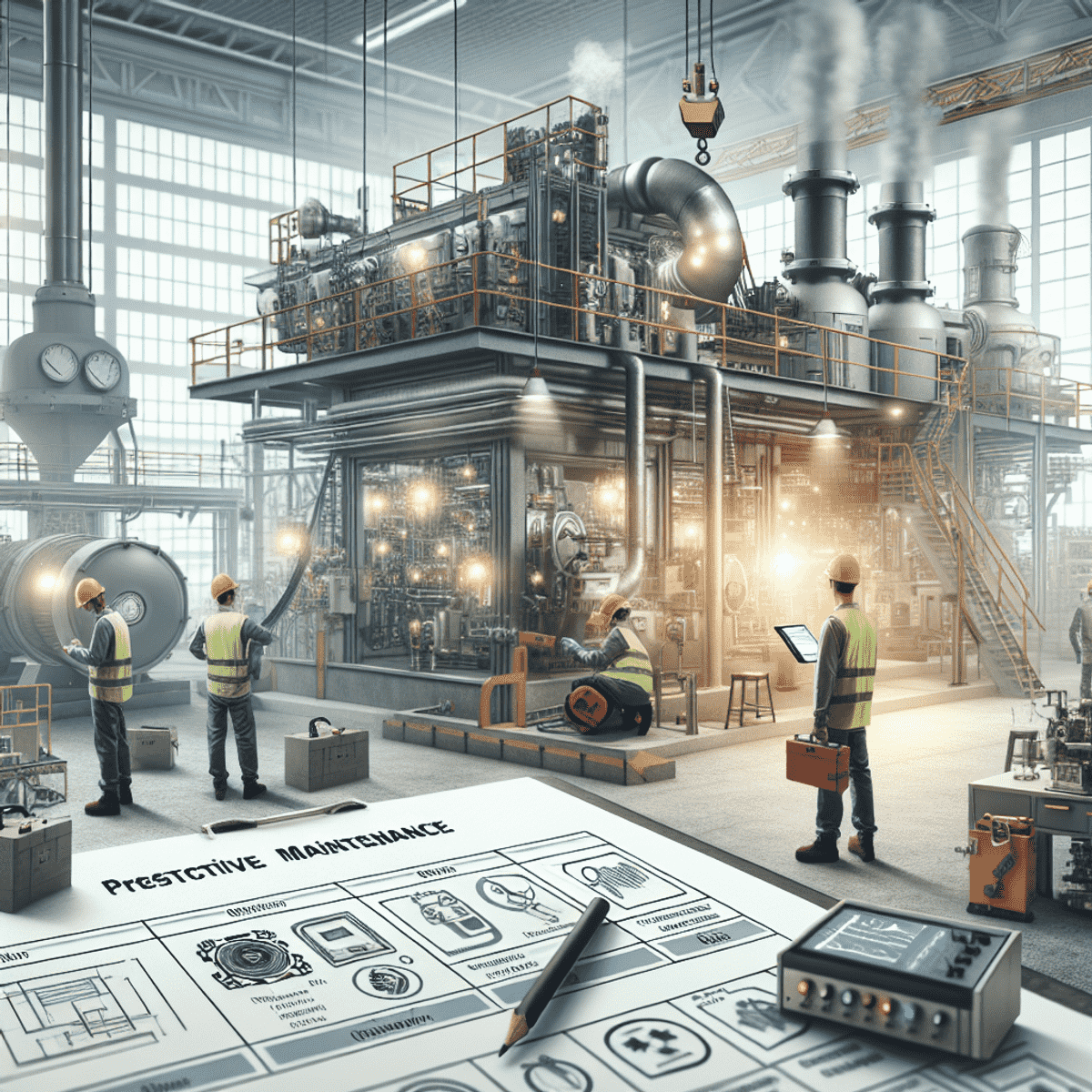

What is Prescriptive Maintenance? Benefits and Implementation

At the core of prescriptive maintenance is data. By collecting and analyzing sensor, maintenance, and operations data from assets, prescriptive maintenance systems build a comprehensive understanding of asset performance. Machine learning…

Facility Maintenance - What is Facility Maintenance?

Facility maintenance encompasses a comprehensive range of activities aimed at ensuring the optimal operational performance, safety, and aesthetic upkeep of buildings, infrastructure, equipment, and systems within a facility. It involves…

Breakdown Maintenance: Types and Examples

Breakdown maintenance, also known as run-to-failure maintenance, is a reactive strategy employed to address equipment failures as they occur. It involves repairing or replacing assets only after they have broken down unexpectedly. Despite…