A Computerized Maintenance Management System (CMMS) is a robust software solution designed to streamline maintenance operations, enhance asset management, and drive operational efficiency within organizations. By leveraging advanced technology, CMMS software plays a pivotal role in reducing downtime, cutting costs, and facilitating data-driven decision-making in maintenance management.

Overview of CMMS

Definition of CMMS Software

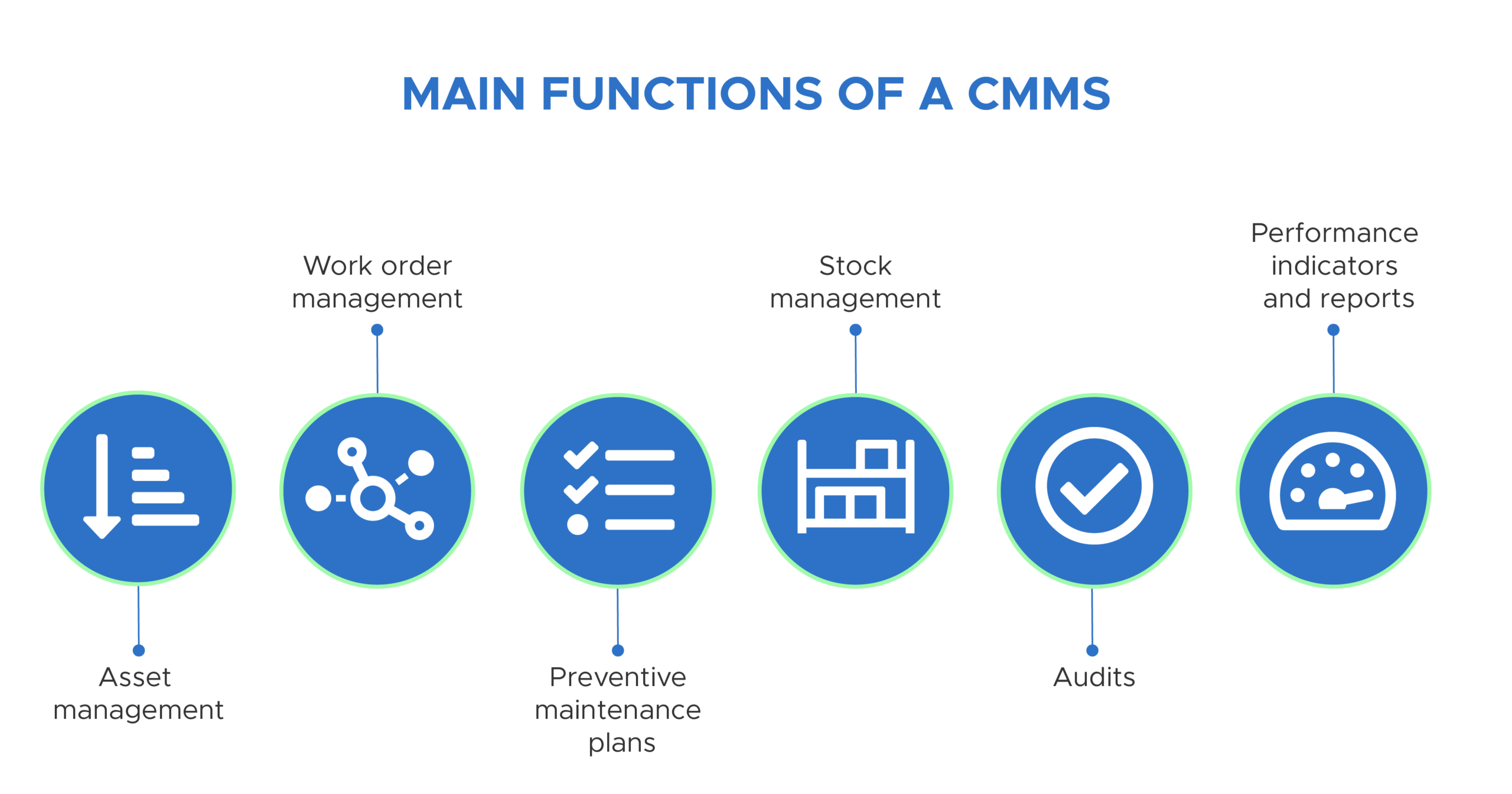

CMMS software serves as a centralized platform for managing a wide array of maintenance-related activities, including asset management, work order scheduling, preventive maintenance planning, inventory control, and performance analysis. By automating traditionally manual processes, CMMS optimizes maintenance workflows, boosts productivity, and ensures optimal utilization of resources.

Main Functions of CMMS

Asset Management: CMMS empowers organizations to effectively track and manage their assets by maintaining detailed records of asset specifications, maintenance history, and lifecycle data. This comprehensive asset management functionality enables better resource allocation, improved asset reliability, and enhanced maintenance planning.

Work Order Management: With robust work order management features, CMMS facilitates the seamless generation, assignment, and tracking of maintenance tasks. Maintenance teams can efficiently prioritize work orders, monitor task progress in real-time, and ensure timely completion of maintenance activities, thereby minimizing downtime and maximizing operational efficiency.

Preventive Maintenance: CMMS software enables organizations to proactively schedule and automate preventive maintenance tasks based on predefined criteria such as time, usage, or condition. By conducting regular inspections and maintenance activities, organizations can prevent equipment failures, extend asset lifespan, and optimize maintenance costs.

Inventory Management: CMMS offers sophisticated inventory management capabilities, allowing organizations to effectively track and control maintenance-related inventory, spare parts, and supplies. By maintaining optimal inventory levels and streamlining procurement processes, CMMS helps reduce inventory carrying costs, minimize stockouts, and ensure timely availability of critical spare parts.

Reporting & Analytics: CMMS provides robust reporting and analytics tools that enable organizations to extract actionable insights from maintenance data. By analyzing key performance metrics such as equipment uptime, maintenance costs, and labor utilization, organizations can identify trends, uncover inefficiencies, and make informed decisions to continuously improve maintenance operations.

Integration with IoT for Enhanced Maintenance Efficiency

In the era of Industry 4.0, the integration of CMMS with Internet of Things (IoT) technology emerges as a game-changer for maintenance management. By leveraging IoT sensors, devices, and connectivity, organizations can harness real-time data to drive predictive maintenance strategies, optimize asset performance, and minimize unplanned downtime.

Benefits of CMMS Integration with IoT

- Real-Time Monitoring: IoT sensors continuously monitor equipment parameters such as temperature, pressure, and vibration, providing maintenance teams with real-time insights into asset health and performance. By integrating IoT data streams with CMMS, organizations can identify potential issues early, proactively address maintenance needs, and prevent costly downtime.

- Predictive Maintenance: By analyzing historical and real-time IoT data, CMMS can predict equipment failures and performance degradation before they occur. Predictive maintenance strategies enable organizations to schedule maintenance activities based on actual asset condition, optimize resource allocation, and maximize asset uptime.

- Condition-Based Maintenance: IoT-enabled CMMS systems facilitate condition-based maintenance by automatically triggering maintenance tasks based on predefined thresholds or equipment conditions. This proactive approach ensures that maintenance interventions are conducted precisely when needed, minimizing the risk of unexpected failures and optimizing asset reliability.

- Remote Monitoring and Diagnostics: With IoT integration, maintenance teams can remotely monitor equipment performance, diagnose issues, and troubleshoot problems without the need for physical inspection. Remote monitoring capabilities enhance operational efficiency, reduce response times, and enable predictive maintenance interventions from anywhere, at any time.

- Data-Driven Decision-Making: By leveraging IoT-generated data alongside CMMS analytics, organizations gain valuable insights into asset performance, maintenance trends, and operational efficiency. This data-driven approach empowers organizations to make informed decisions, optimize maintenance strategies, and drive continuous improvement across the organization.

Conclusion

In conclusion, a well-implemented CMMS, augmented by IoT integration, is instrumental in revolutionizing maintenance management practices and driving operational excellence. By harnessing the power of CMMS software and IoT technology, organizations can achieve greater efficiency, reliability, and cost-effectiveness in their maintenance operations, ultimately gaining a competitive edge in today’s dynamic business landscape.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…

Discover Our Products

Sensemore Predictive Maintenance Solution

If you enjoyed this blog, explore our Predictive Maintenance Solution page.