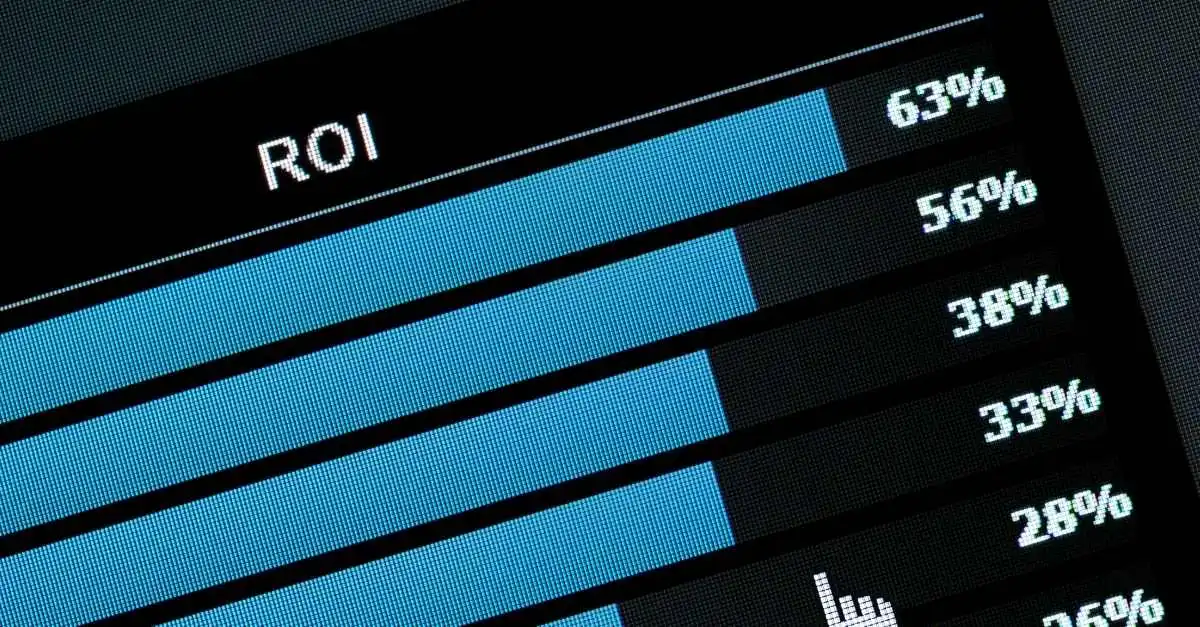

The Key Factors Impacting ROI in Predictive Maintenance

The adoption of predictive maintenance strategies has emerged as a pivotal factor influencing the Return on Investment (ROI) for businesses. As organizations seek to optimize their maintenance practices, understanding the key elements that…

Predictive Maintenance Strategies to Optimize Machine Health

Just as the human body requires regular health check-ups to ensure optimal functioning, machines too require a certain level of care and maintenance. This is where the concept of predictive maintenance enters the picture, making waves in…

Prognostic Methods in Predictive Maintenance Applications

The maintenance of complex systems and machinery plays a critical role in ensuring their optimal performance and longevity. However, traditional approaches to maintenance, such as reactive or preventive strategies, are often limited in…

Condition Monitoring: Smarter Future in Industrial Maintenance

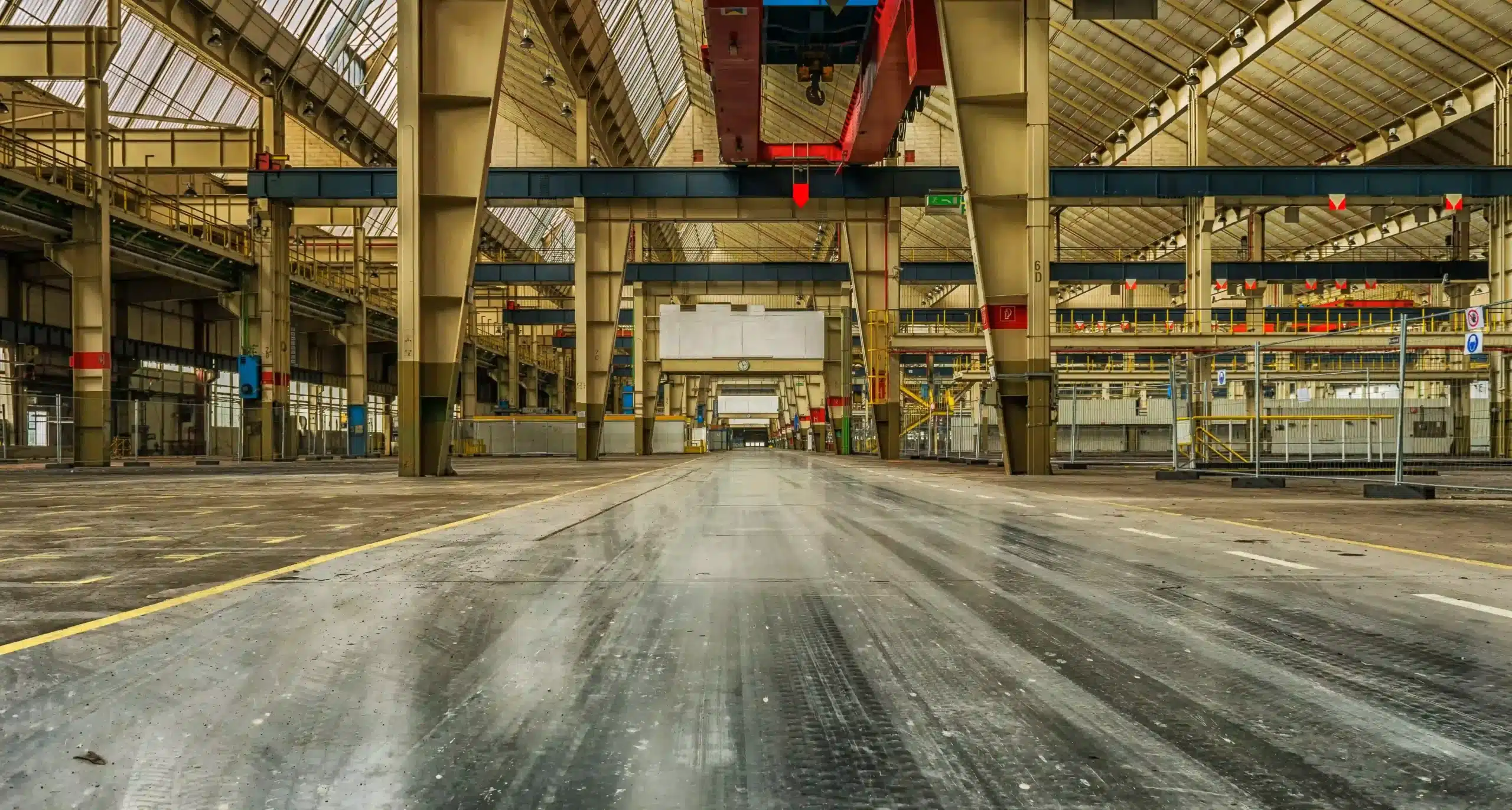

From manufacturing plants to transportation systems, machines are the base of our modern society. However, these machines are not immune to wear and tear. Over time, they undergo stress, experience malfunctions, and eventually, break down.…

Predictive Maintenance and Pulp & Paper Industry

Pulp and paper production is a vital industry that produces a wide range of products, from paper and cardboard to tissue and pulp. However, the production process is complex, energy-intensive, and requires a large number of machines and…

Predictive Maintenance with Electrical Signature Analysis (ESA)

As a result of targeting more reliable and more sustainable factories by reducing the need for human resources, the increasing needs of the industry, and the costs caused by these needs, topics like machine health and predictive…

Understanding Rotating Machinery Data

Machinery data encompasses the extensive set of information generated by rotating machinery during its operational cycles. This data comprises various measurable parameters, performance metrics, and operational characteristics, providing a…

Preventive vs Predictive Maintenance

Maintenance operations ensure mechanical systems remain in working order, but not all maintenance strategies are created equal. Two common approaches are preventive maintenance vs predictive maintenance, each with its unique methods and…

First Step in AI-Based Predictive Maintenance

Predictive maintenance using AI can prevent equipment failures by predicting when a maintenance action is required. Rule-based systems use hard-coded thresholds, while ML-based systems use advanced modelling to predict failure. Anomaly…

Integration of Condition Monitoring into Existing Systems

We talked about condition monitoring and its importance in our previous blog post. The basic principle in condition monitoring is to detect failures in machinery and equipment to predict using equipment-specific condition parameters, such…