Just as the human body requires regular health check-ups to ensure optimal functioning, machines too require a certain level of care and maintenance. This is where the concept of predictive maintenance enters the picture, making waves in industries across the globe.

Predictive maintenance is a proactive strategy that involves monitoring equipment during operation to identify potential failures before they happen. Think of it as a form of “preventative medicine” for machines. It’s an approach that enables businesses to anticipate and address machine malfunctions, thereby reducing downtime and improving overall operational efficiency. Instead of waiting for a machine to fail or scheduling maintenance at regular intervals, predictive maintenance ensures maintenance is only performed when necessary, saving time and resources. This is a far cry from the reactive maintenance practices of the past where a ‘fix it when it breaks’ mentality prevailed.

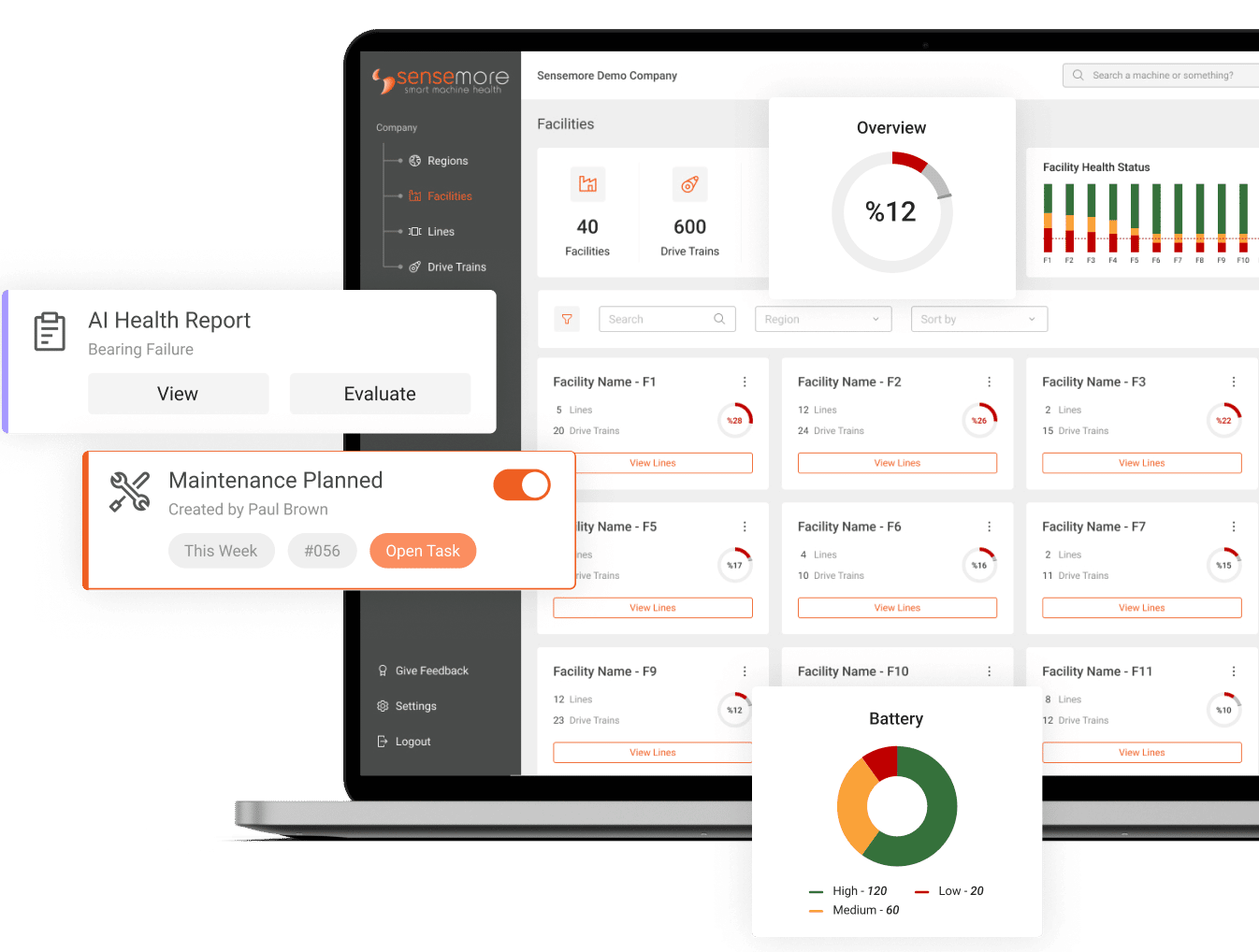

The importance of predictive maintenance has been further amplified by advancements in technology. With the advent of the Internet of Things (IoT), cloud computing, and data analytics, predictive maintenance has evolved from a theoretical concept to a practical, cost-saving reality. This technological evolution has allowed businesses to leverage real-time data, identify patterns, and use this information to predict future machine performance.

Predictive maintenance is more than just a buzzword. It’s a revolution in machine health optimization. As per a study conducted by Deloitte, companies that have adopted predictive maintenance have seen an increase in equipment uptime by 10-20%, a 25-30% reduction in maintenance costs, and a 70-75% decrease in breakdowns. This is testament to the tremendous potential that predictive maintenance holds for businesses seeking to enhance their operational efficiencies and profitability.

Understanding the Concept of Machine Health

Similar to human health, machine health refers to the overall functioning state of a machine. It is a measure of how effectively and efficiently a machine or system is operating. A healthy machine is one that operates at its optimal capacity with minimal disruptions, and like our health, machine health is something that needs to be proactively managed.

Maintaining optimal machine health is not just about prolonging the lifespan of a machine, but it’s also about ensuring maximum productivity and efficiency. When machines are healthy, they operate at their best, providing companies with a steady stream of production and a reliable base upon which they can plan their operations and growth.

The cost of machine downtime due to health issues can be enormous. Unplanned downtime can disrupt production schedules, delay deliveries, result in lost sales, and even damage a company’s reputation. According to Aberdeen Research, the average cost of downtime across all businesses is approximately $260,000 per hour! Furthermore, a report by ServiceMax revealed that 82% of companies have experienced unplanned downtime over the past three years, which could have been avoided with a predictive maintenance strategy. These staggering numbers showcase the critical importance of maintaining machine health.

As such, maintaining machine health is not a luxury but a necessity for modern businesses. It requires a blend of reactive, preventive, and predictive measures. However, the future undoubtedly lies in predictive maintenance, with its promise of optimizing machine health and minimizing downtime. Through predictive maintenance, we can harness the power of data and advanced analytics to keep our machines running smoothly, ensuring the health of our businesses in the process. The evolution and growth of machine health optimization are just beginning, and the potential for innovation is enormous.

The Power of Predictive Maintenance

Predictive maintenance, as its name implies, is the practice of predicting when a piece of equipment might fail so that maintenance can be performed just-in-time to prevent that failure. It’s about being proactive rather than reactive, focusing on prevention rather than cure. Predictive maintenance uses advanced tools, technologies, and techniques to monitor and analyze the condition of equipment during normal operation. It’s an approach that fundamentally changes the game from ‘fixing’ machines to ‘maintaining’ them.

In predictive maintenance, machines are fitted with sensors that continuously collect data about parameters like temperature, vibration, and pressure. This data is then analyzed, typically using machine learning algorithms, to predict when a machine is likely to fail or when its performance is expected to deteriorate. With this information in hand, organizations can schedule maintenance precisely when it’s needed – not a moment too soon or too late.

Predictive maintenance thus prevents machine failure by enabling timely maintenance interventions. This prevents small issues from becoming larger problems that could cause a machine to fail or disrupt production. It’s a bit like spotting a small health issue during a routine medical check-up before it evolves into a serious condition. By catching problems early, predictive maintenance can save businesses significant time, money, and resources.

Key Strategies for Effective Predictive Maintenance

Data Collection and Analysis

At the heart of predictive maintenance lies data. The more data you have about your machines, the better you can understand their health and predict their future performance. Data collection begins with installing sensors on your machines to monitor various parameters such as temperature, pressure, vibration, and more. These sensors collect data in real-time, providing a steady stream of information about your machine’s health.

This collected data, however, is only as useful as the insights you can draw from it. This is where data analysis comes into play. Data analysis techniques are used to identify patterns and trends in the collected data. Advanced statistical techniques, machine learning, and artificial intelligence are often used to analyze this data, extracting valuable insights that can be used to predict future machine performance.

Types of data relevant for machine health prediction can vary greatly depending on the type of equipment and the specific context of its use. However, some common types include vibration data, temperature data, oil analysis data, and ultrasonic data, among others.

Implementing Machine Learning and AI

In the world of predictive maintenance, machine learning and AI are nothing short of transformative. They can analyze vast amounts of data, identifying complex patterns that would be impossible for humans to discern. They learn from the data, improving their predictions over time.

Machine learning algorithms can be trained to recognize the signs of impending machine failure. For instance, they might learn that a particular combination of vibration and temperature levels typically precedes a failure. Once trained, these algorithms can monitor real-time data for these signs, alerting maintenance teams when they’re detected.

The benefits of integrating machine learning and AI into predictive maintenance are manifold. They increase the accuracy of predictions, allowing maintenance to be scheduled more precisely and reducing the likelihood of unexpected failures. They can handle vast amounts of data, making them suitable for even the largest and most complex operations.

Real-Time Monitoring and Alerts

Real-time monitoring is another critical component of effective predictive maintenance. Sensors continuously monitor equipment and send data in real-time to a central system where it’s analyzed.

Real-time alerts, generated by the system when it identifies potential problems, are incredibly valuable. These alerts can trigger immediate action, whether that’s a closer inspection of the machine, a minor adjustment, or scheduling maintenance work. This ensures that potential issues are addressed promptly, reducing the likelihood of machine failure and the costly downtime that comes with it.

Regular and Scheduled Maintenance Checks

While the use of advanced technologies is revolutionizing predictive maintenance, traditional maintenance practices still have their place. Regular and scheduled maintenance checks form the foundation of a solid predictive maintenance strategy. They provide opportunities to physically inspect and maintain machines, ensuring they’re in good working order.

Planning and scheduling these checks is crucial. The objective is to balance the need for machine uptime with the need for maintenance. Checks should be scheduled based on the insights derived from data analysis and machine learning predictions. If the data indicates that a machine typically starts showing signs of wear after a certain period of operation, that’s when you should schedule a maintenance check.

Employee Training and Engagement

Predictive maintenance is a team effort. While it relies heavily on technology, it’s the human component – your employees – that ultimately determines its success.

Employees need to be trained on the use of predictive maintenance technologies. They need to understand how to interpret the data and alerts, and how to take appropriate action. But more than that, they need to be engaged in the process. They need to understand the importance of predictive maintenance, how it benefits them and the organization, and feel empowered to contribute to its success.

Employee engagement can be improved through regular training sessions, feedback, and by cultivating a culture that values proactive maintenance. Recognizing and rewarding employees for their role in maintaining machine health can also drive engagement.

The Future of Predictive Maintenance

The future of predictive maintenance lies in the convergence of several technological advancements. Among them, the Internet of Things (IoT) is playing a pivotal role. IoT devices, which can be installed on any piece of equipment, collect real-time data about the machine’s operation and send it to a central system for analysis.

This continuous flow of data can be used to monitor machine health in real-time and predict future performance. This not only improves the accuracy of predictive maintenance but also enables it to be applied to a wider range of equipment, including those in remote or difficult-to-access locations.

Moreover, advancements in technologies like cloud computing, big data analytics, and artificial intelligence are also driving the evolution of predictive maintenance. They’re enabling more sophisticated data analysis, improving the accuracy of predictions, and making predictive maintenance more accessible and affordable for businesses of all sizes.

The combination of these technologies is reshaping the landscape of predictive maintenance, enabling it to move beyond simple failure prediction and towards a more comprehensive understanding of machine health. It’s paving the way for prescriptive maintenance, where not only the “when” of a potential failure is predicted but also the “why” and the “how” to prevent it.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…

Sensemore Predictive Maintenance Solution

If you enjoyed this blog, explore our Predictive Maintenance Solution page.