The adoption of predictive maintenance strategies has emerged as a pivotal factor influencing the Return on Investment (ROI) for businesses. As organizations seek to optimize their maintenance practices, understanding the key elements that impact ROI becomes imperative. This introduction sets the stage for a comprehensive exploration of the financial dynamics associated with predictive maintenance initiatives.

ROI in Predictive Maintenance

Understanding Return on Investment (ROI) in Industrial Settings

Predictive maintenance is more than a proactive approach to equipment upkeep; it is a strategic investment with the potential for substantial returns. This section delves into the foundational concepts of ROI in industrial settings, elucidating the methodologies used to quantify the financial gains derived from predictive maintenance implementations. By understanding the intricacies of ROI assessment, organizations can make informed decisions about resource allocation and technology adoption.

Tangible and Intangible Benefits of Predictive Maintenance

Tangible Benefits

Tangible gains are those directly quantifiable in monetary terms. This subsection explores the concrete advantages of predictive maintenance, including cost reductions, minimized downtime, and increased operational efficiency. Real-world examples and metrics illustrate how organizations can tangibly measure the impact on their bottom line.

Intangible Benefits

Beyond the quantifiable metrics lie the intangible benefits that contribute significantly to the overall value proposition of predictive maintenance. Improved safety, enhanced product quality, and a positive impact on employee morale are among the intangible advantages explored in this section, demonstrating the multifaceted nature of returns from predictive maintenance investments.

Measuring and Quantifying ROI Metrics

Key Performance Indicators (KPIs) for ROI Assessment

To gauge the success of predictive maintenance initiatives, organizations rely on Key Performance Indicators (KPIs) tailored for ROI assessment. This section delves into the crucial metrics that serve as benchmarks for evaluating the effectiveness of predictive maintenance strategies. From Mean Time Between Failures (MTBF) to Overall Equipment Effectiveness (OEE), attendees will gain insights into the quantitative measures that facilitate a comprehensive understanding of the financial impact.

Benchmarking Against Industry Standards

Comparative analysis against industry benchmarks is pivotal for contextualizing the performance of predictive maintenance initiatives. This subsection explores the importance of benchmarking and outlines the process of aligning organizational outcomes with industry standards. By benchmarking, businesses can assess their competitive positioning, identify areas for improvement, and ascertain whether their ROI metrics align with the broader industrial landscape.

Factors Impacting ROI in Predictive Maintenance

Technology used in Predictive Maintenance

The choice of technology is a critical determinant of ROI in predictive maintenance. Advanced sensors, data analytics tools, machine learning algorithms, and communication systems all come at a cost. However, these costs must be measured against the value these technologies bring. For example, sophisticated sensors may increase the initial investment, but if they offer superior data accuracy that results in more effective predictive modeling and less downtime, the ROI could justify the higher cost.

Skilled Personnel

Predictive Maintenance is a sophisticated process that requires a certain level of expertise. It necessitates a team of skilled individuals who can manage and interpret data, operate the technologies, and make informed decisions. Hiring or training these personnel involves expenses. However, a competent team can increase the efficiency and effectiveness of predictive maintenance operations, leading to higher ROI.

Quality of Data

Data is the backbone of Predictive Maintenance. The quality of data collected can significantly impact the accuracy of the predictions and consequently, the ROI. Inaccurate or incomplete data can lead to incorrect predictions, potentially resulting in equipment failure and costly repairs. Thus, investing in reliable data collection and management systems is crucial for optimizing ROI.

Initial Investment Costs

The initial investment cost is a significant factor in determining the ROI. These costs include the purchase of hardware and software, installation costs, training costs, and other related expenses. A higher initial investment can make it more challenging to achieve a positive ROI, particularly in the short term. Therefore, it’s essential to ensure that these costs are justified by the expected long-term benefits.

Implementation Strategy

Last but not least, the implementation strategy of the predictive maintenance program plays a pivotal role in determining the ROI. A well-planned strategy that prioritizes critical equipment, ensures seamless integration with existing systems, and includes regular reviews and adjustments can maximize the ROI. Conversely, a haphazard or poorly executed strategy can lead to under-optimized ROI, rendering the predictive maintenance program a financial burden rather than a boon.

Example ROI Calculation for Predictive Maintenance Application

1. Initial Investment:

Cost of Predictive Maintenance System $200,000

Implementation and Integration Costs $50,000

Training Expenses $20,000

System Maintenance and Support (annual) $15,000

Total Initial Investment: $285,000

2. Cost Savings:

A. Reduction in Unplanned Downtime:

Average Downtime Cost per Hour $5,000

Expected Reduction in Downtime 20 hours per month

Annual Savings $1,200,000

B. Decreased Maintenance Labor Costs:

Current Annual Maintenance Labor Costs $120,000

Anticipated Reduction 0,3

Annual Savings $36,000

C. Extended Equipment Lifespan:

Avoided Replacement Cost for One Component $30,000

Number of Components per Year 2

Annual Savings $60,000

D. Energy Efficiency Gains:

Energy Cost Savings (annual) $10,000

Annual Savings $10,000

Total Annual Cost Savings: $1,306,000

3. Increased Productivity:

Improved Equipment Availability 15% increase

Current Annual Revenue $2,000,000

Estimated Annual Increase in Revenue $300,000

4. Safety and Compliance:

Reduced Safety Incidents 20% decrease

Average Cost per Safety Incident $5,000

Enhanced Regulatory Compliance (avoidance) $40,000

Estimated Annual Value $60,000

5. Total Annual Value Generated $1,666,000

6. Return on Investment (ROI):

Total Annual Value – Annual Maintenance and Support / Initial Investment 581.75%

How Technology Affects ROI in Predictive Maintenance

Investing in the right technology for Predictive Maintenance is like buying a high-performance vehicle. A superior vehicle requires a significant investment upfront, but it rewards you with exceptional performance and fewer breakdowns. The same holds true for predictive maintenance technology.

The integration of advanced IoT sensors and AI-driven analytics platforms can significantly enhance prediction accuracy, reducing the likelihood of unforeseen breakdowns. It might necessitate a substantial initial investment, but the long-term benefits – reduced downtime, prolonged asset life, and fewer replacement costs – can lead to a significantly improved ROI. The key here is to strategically select technology that aligns with your organization’s unique needs and goals.

The Role of Skilled Personnel in Optimizing ROI

Even with the best technology at hand, the success of PdM lies in the hands of those who operate it. Skilled personnel are vital in interpreting data, making timely decisions, and ensuring the smooth running of predictive maintenance technologies.

Investing in the recruitment or training of proficient personnel may seem expensive initially. However, the higher efficiency, fewer mistakes, and improved decision-making they bring can dramatically enhance ROI in the long run. Hence, investing in human capital is just as crucial as investing in technology for PdM.

The Influence of Data Quality on ROI

Data, in the realm of PdM, is like the fuel that drives the system. Without high-quality data, even the most advanced predictive maintenance technologies can falter.

Quality data helps to create more accurate predictive models, which in turn lead to more effective maintenance scheduling and a decrease in unscheduled downtime. While ensuring high-quality data might involve the deployment of more sophisticated sensors or rigorous data cleaning processes, the impact on the ROI is significantly positive. Remember, garbage in equals garbage out. So, make sure the data going into your predictive maintenance system is of the highest quality.

Cost-Benefit Analysis of Initial Investment

ROI in predictive maintenance is largely a long-term game. The upfront costs for implementing a robust PdM program can be hefty. This includes purchasing the required technology, hiring or training personnel, and setting up systems for data management.

However, these initial costs should be weighed against the long-term benefits – savings from reduced maintenance costs, increased asset lifespan, and decreased downtime. Often, these benefits significantly outweigh the initial investment over time, leading to a favorable ROI. Hence, a thorough cost-benefit analysis is necessary before committing to an initial investment in PdM.

The Impact of the Implementation Strategy on ROI

The implementation strategy of a predictive maintenance program can be likened to the blueprint of a building. A well-planned and executed strategy ensures that the PdM program stands strong and delivers the desired results.

A sound strategy involves identifying critical assets, setting clear objectives, integrating predictive maintenance technology seamlessly with existing systems, and regularly reviewing and fine-tuning the process. A misstep in any of these stages could lead to a subpar ROI. Thus, a thoughtful and comprehensive implementation strategy is paramount for optimizing ROI in predictive maintenance.

Time-to-ROI in Predictive Maintenance Implementations

Defining and Measuring Time-to-ROI

Understanding the timeline for realizing returns on investment is crucial in predictive maintenance implementations. This section defines and measures Time-to-ROI, providing attendees with a clear comprehension of the duration it takes for proactive maintenance strategies to yield tangible financial benefits. By establishing a common understanding of the temporal aspects, organizations can set realistic expectations and plan for the optimal deployment of resources.

Strategies for Accelerating Time-to-ROI

Efficiency in achieving returns is often a key consideration in any investment. This part of the lecture explores strategies to expedite Time-to-ROI in predictive maintenance implementations. Attendees will gain insights into best practices, proactive measures, and approaches that organizations can adopt to streamline processes and accelerate the realization of financial gains.

Comparative ROI Analysis: Predictive vs. Reactive Maintenance

Assessing Costs and Benefits of Reactive Maintenance

This section delves into the conventional approach of reactive maintenance, examining the costs and benefits associated with addressing issues only when they arise. Attendees will gain insights into the financial implications of unscheduled downtime, emergency repairs, and the potential long-term consequences of relying on a reactive maintenance strategy.

ROI Comparison with Traditional Maintenance Approaches

A comparative analysis is essential to highlight the stark differences between predictive and reactive maintenance in terms of ROI. This part of the lecture systematically compares the return on investment achieved through predictive maintenance initiatives with the outcomes of traditional, reactive maintenance approaches. Attendees will gain a nuanced understanding of the financial gains and drawbacks associated with each strategy, providing a foundation for informed decision-making.

Justifying the Transition to Predictive Maintenance

The transition from reactive to predictive maintenance is not just a technological shift but a strategic decision with significant financial implications. This subsection focuses on justifying the rationale behind transitioning to predictive maintenance by showcasing how the financial benefits outweigh the costs. Attendees will explore real-world examples and scenarios where organizations successfully justified and navigated the transition, establishing a roadmap for others contemplating a similar strategic shift.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…

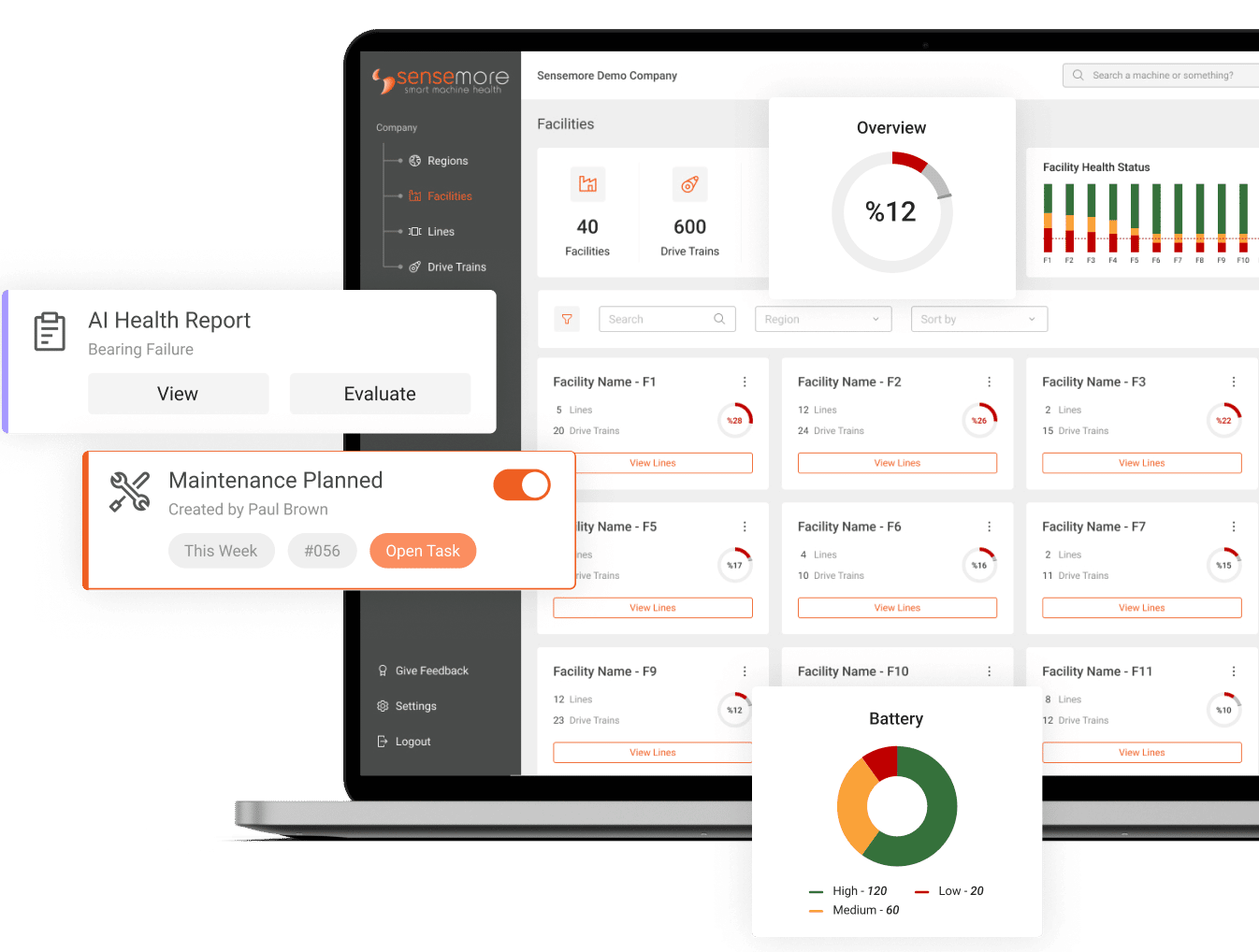

Sensemore Predictive Maintenance Solution

If you enjoyed this blog, explore our Predictive Maintenance Solution page.