Predictive maintenance using AI can prevent equipment failures by predicting when a maintenance action is required. Rule-based systems use hard-coded thresholds, while ML-based systems use advanced modelling to predict failure. Anomaly detection in rotating machinery is a key step in AI-based predictive maintenance.

With the increasing demand of IoT in the age of digitalization, data-driven maintenance optimization of industrial equipment is one of the most trending topics among maintenance professionals. Firstly, data gathered by various sensors placed on the machines or embedded in the machine itself are pre-processed. Later on, this data is used in decision-support systems with the help of Artificial Intelligence (AI) tools. In this article, we will talk about how artificial intelligence applications can be implemented in the predictive maintenance area.

Rule-Based Systems vs. AI-Based Predictive Maintenance

Previously, Predictive Maintenance was just a rule-based system. But It was lacking as a real solution to the machine health problem. In rule-based predictive maintenance; maintenance is performed based on hard-coded thresholds, and an alert is sent if a measurement exceeds the thresholds. For example, it is an application of rule-based predictive maintenance for a pump to generate an alarm when the RMS of vibration signal exceeds 7.1 mm/s. This kind of predictive maintenance application is widely used with the help of ready-made ISO standards along with traditional methods. Consider a temperature sensor in a critical piece of equipment. If the rule set for that sensor states that temperatures above 60°C are abnormal, an alert is triggered anytime this threshold is breached, indicating potential equipment failure. This method is straightforward to implement, but it falls short when dealing with larger and more complex machinery.

Predictive Maintenance has evolved from rule-based predictive maintenance to machine learning-based predictive maintenance. In machine learning-based predictive maintenance, advanced analytics and machine learning techniques are used to predict when the next failure might potentially occur and the machinery is pre-maintained accordingly. This subject is pretty huge to tackle all at once, therefore in this article, anomaly detection in rotating machinery, which is one of the first steps of machine learning-based predictive maintenance, will be emphasized.

Complex machinery often operates under fluctuating conditions and produces vast amounts of data. This high-dimensional data can include various parameters such as temperature, pressure, vibrations, and more. Rule-based systems can struggle to effectively interpret and respond to this amount of data. The key difference lies in the system’s ability to learn from data as opposed to simply following predefined rules. Unlike rule-based systems that react to anomalies, AI-based systems proactively identify potential issues before they become critical.

Here’s how:

- Machine Mode Analysis: This predictive maintenance approach uses unsupervised learning to analyze sensor readings and detect patterns that indicate the normal operation of the machinery.

- Anomaly Detection: Once these patterns are established, any deviations from them can be flagged as anomalies, signaling potential issues.

- Human Inspection & Labelling: These anomalies can then be further investigated through human inspection and labeled with their root causes.

By human inspection into the process, we facilitate a semi-supervised learning process for future anomaly detection. Over time, this allows the system to become smarter and more accurate in predicting machinery failures.

Anomaly Detection in Rotating Machinery

A rotating machine such as a pump or fan is going to deteriorate from regular use and will begin to produce symptoms that we might call “anomalies”. This should not be considered a complete shutdown state, but rather a warning that the machine is not in optimal condition and might need to undergo maintenance.

The first tool for detecting these anomalies is sensors. The sensor and sensor outputs used in anomaly detection have a very important place in the anomaly detection performance. Even when sensors with appropriate capabilities are used, there are still the challenges of data pre-processing and model building. Without the right combination of these three factors, it would be impossible to produce a robust anomaly detection system, causing unnecessary loss of time and effort, false-positive alarms or in extreme cases, serious damage to the equipment. If the historical signal data on the health status of a machinery (such as an archive of labelled data including healthy and anomaly samples) is available, a supervised learning approach can be used for preparing an AI-based predictive maintenance model. However, this is rarely the case, thus the machine learning model needs to be trained using a region acceptable as “normal”. Then a deviation metric could be calculated in order to detect anomalous new measurements.

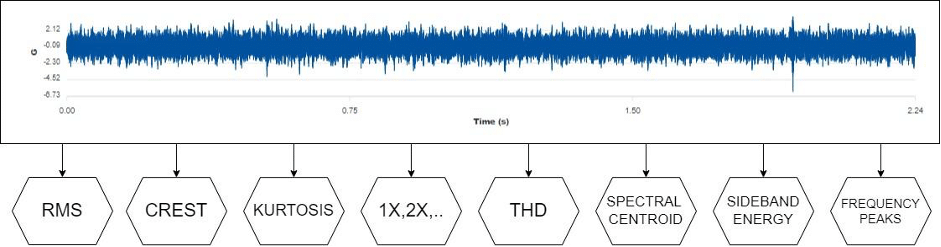

Feature Extraction

Rotating equipment naturally generates vibrations. The aim is to keep these vibrations at acceptable levels to ensure production reliability. Although various different sensors can be used in predictive maintenance applications of rotating equipment, the most fundamental measurement unit is vibration. The vibration signal can be directly implemented into an AI model. However, processing the raw signal, extracting its most informative features without losing meaningful parts and feeding those features into a model, generally yields a better performance. Two main sets of features extractable from a vibration signal are time domain and frequency domain feature sets.

Fig. 1 Some Extracted Features from Acceleration Signal

While metrics such as RMS, Crest, Kurtosis, Peak can be obtained from the time domain, features such as total harmonic distortion, 1X, 2X…nX harmonic indicators, spectral centroid and sideband energy are extracted from the frequency domain. On the other hand, it is equally important to keep a record of the rotation speed of the machinery for harmonic analysis independent of the vibration sensor. Using time and frequency domain features from 3-axis vibration sensor data, it is possible train a machine learning model with over 20,000 features. So, the machine learning model can compare and separate these features in multidimensional space better than the human eye can distinguish data in 2D and 3D spaces. This enables the detection of even the most sensitive anomalies through an AI model.

Machine Mode Analysis for AI-Based Predictive Maintenance

There are hundreds of different machine types that vary according to the usage area in the industry. Many of these machines operate in different cycles, power and processes arising from factors such as changing production speed and raw materials. For example, a simple rolling mill can be operated at different speeds depending on the desired material quality, material thickness and production speed. Vibration data of the machine will also vary depending on these conditions. In rule-based predictive maintenance applications, unwanted anomaly alarms could occur due to an expected change in one of these parameters. This approach could cause many false positive alarms. In order to mitigate this, each process parameter (speed, power, etc.) together with sample signals for them should be included in training of an appropriate AI-based predictive maintenance model. After that, one can determine the machine working modes as well as derivation from these modes using the model.

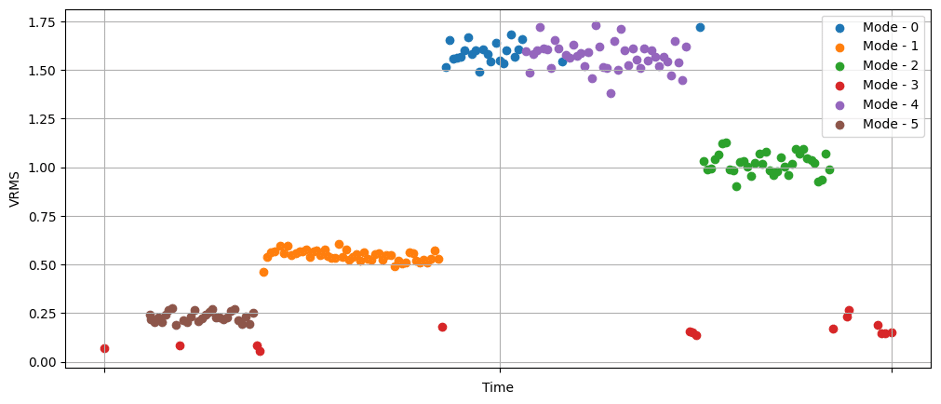

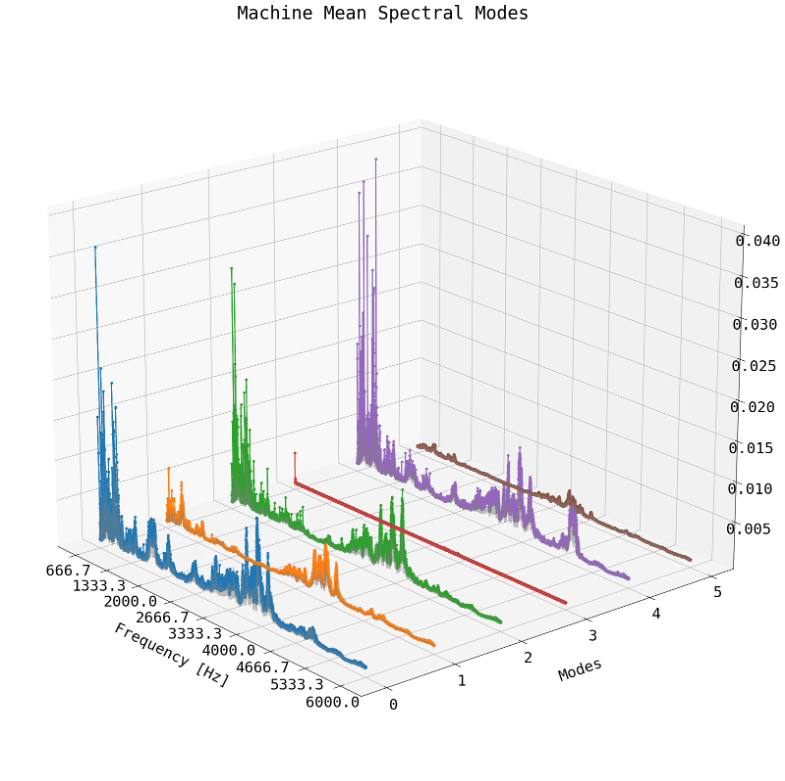

In the example below (Fig. 2), vibration data were collected at 4 different speeds from a test roller. After the model training, it was observed that there were 6 different distinct modes. In these modes, 4 of them belong to 4 different working speeds of the roller, 1 of them is the mode for the machine off state and the last mode is the mode in which the anomalies occur.

Fig. 2 Scatter Plot of Machine Modes

If the measurements are not colored in the chart above, we could think that there are only 5 different groups. However, as can be seen in the graph, the model has 6 different modes. Further analysis has shown that one of the rotation speeds of the machinery satisfies the critical speed condition of the machine, amplifying a mechanical looseness that was present in the machine assembly and coupling, over time (Modes 0 and 4 in Fig.2). This creates a group of abnormal measurements which could have been quite harder to detect without a AI model.

Fig. 3 Machine Modes of Spectrum Signatures

A summary of spectral signatures of the extracted machine modes can be seen in the above animation and in the waterfall graph below (Fig. 3 and Fig. 4). We can see that operation modes are distinctly different. However, it would be very challenging to distinguish these two measurements by just by looking at the VRMS values. Of course, we can argue that VRMS is an insufficient telemetry for the analysis of high frequency vibrations. Although it varies from case to case, static telemetry alarms such as VRMS and GRMS alarms rarely ensure satisfactory accuracy in anomaly detection. On the other hand, transferring numerous spectral and time domain information to the machine learning model provides a more robust approach to anomaly detection. Machine mode analysis both eases the detection of anomalous measurements and speeds up inspections by summarizing all measurements into groups.

Fig. 4 Waterfall Plot of 6 Machine Modes

Conclusion

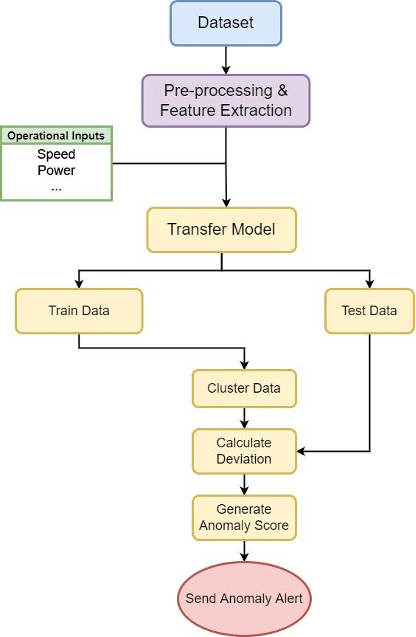

In the absence of historically labeled data where supervised learning is not possible, anomaly detection using unsupervised learning is the best approach as a first step in AI-based predictive maintenance. In order to implement this, an appropriate AI model should be train using meaningful features extracted from the raw sensor data. As detected anomalies are approved by human inspection, a semi-supervised model approach where detected anomalies are labelled for their root causes can be adopted. Using labeled data, root causes of each anomaly can be estimated.

Fig. 5 Flowchart of Algorithm

A generalized AI model based on data can be very difficult to obtain due to variations such as load state, transmission types and working conditions. Because of this, starting the application using machine-specific transfer learning methods and in parallel, using anomaly detection and labelling process would be a powerful first step to take in the AI-Based Predictive Maintenance journey.

Scalability and Adaptability in AI-Based Predictive Maintenance Systems

AI-based predictive maintenance systems are revolutionizing the way industries tackle equipment maintenance. At the heart of this exciting shift is the scalability and adaptability these systems offer. These two critical features bolster their effectiveness across numerous industrial scenarios.

1. Handling Large Volumes of Data

AI-based predictive maintenance systems are designed to manage vast quantities of data with ease. This data can come from a multitude of machines spread over various sites, making the system significantly scalable. Their ability to handle such high-volume data paves the way for:

- In-depth machine analysis: When supplied with ample data, these systems can delve deep into machinery performance, identifying patterns that may be indicative of future machinery failures.

- Comprehensive site overview: With data from numerous machines across different sites, these systems provide a holistic view of the overall health status of your machinery, thus enabling more efficient maintenance planning.

2. Learning and Adapting to Unique Machine Setups

Every machine is unique, with its own set of operating conditions and potential points of failure. AI-based predictive maintenance systems embrace this diversity by learning from each unique machine setup and adapting their predictive models accordingly. This adaptability grants them an edge in:

- Personalized predictions: The system tailors its predictive models to each machine’s distinct characteristics, resulting in more accurate predictions.

- Enhanced reliability: By understanding each machine’s intricacies, these systems can reliably predict potential issues, which leads to fewer unexpected machine breakdowns.

3. Continuous Model Updates

Perhaps one of the most compelling features of AI-based predictive maintenance systems is their ability to continuously update their models as new data comes in. This consistent learning allows them to swiftly adapt to changes in machinery or operating conditions.

- Real-time adaptation: These systems are not static; they grow and evolve with your machinery. Any changes in machine operations are quickly incorporated into the predictive models, ensuring that the system remains up-to-date and relevant.

- Proactive maintenance planning: With constant updates to machine status and potential risks, these systems enable proactive maintenance planning, preventing costly downtime.

The scalability and adaptability of AI-based predictive maintenance systems make them a highly valuable tool for industries. They offer a level of flexibility and effectiveness that is unmatched by traditional rule-based systems, leading to more efficient and effective predictive maintenance strategies.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…