November 18, 2024

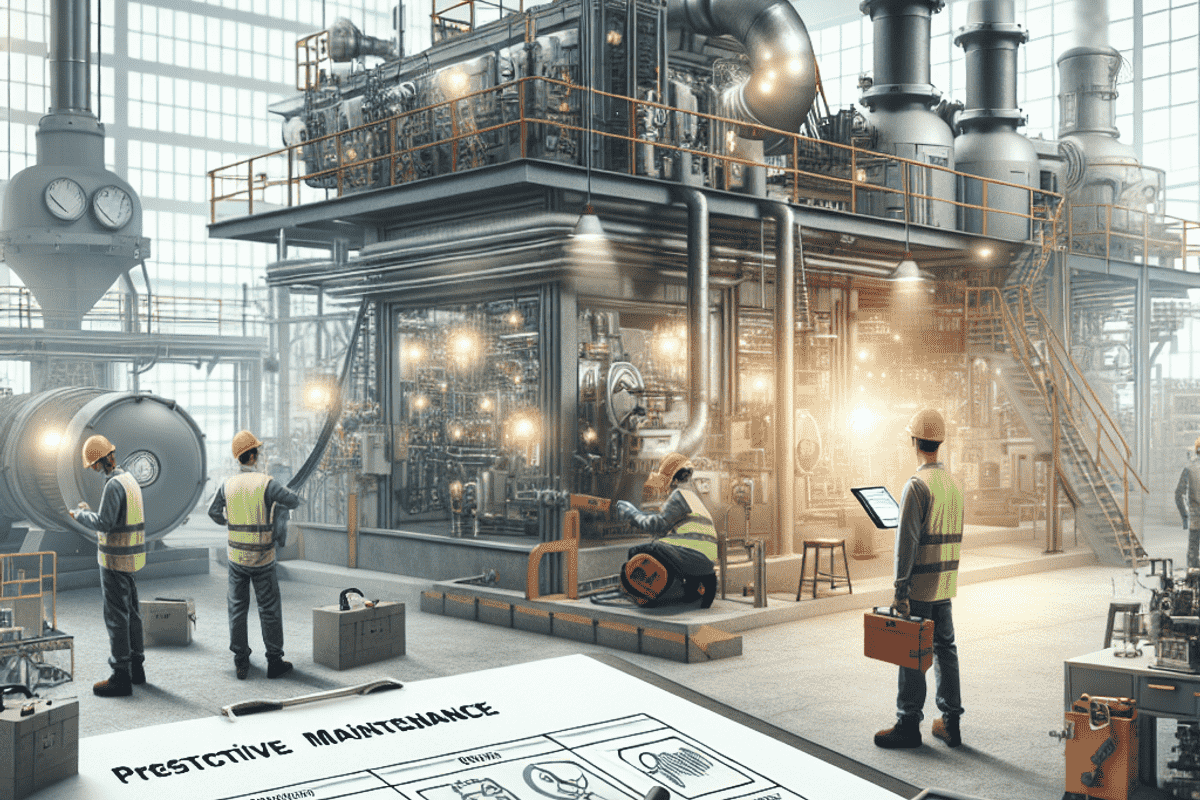

A Sneak Peak to the Future of Airport Operations: Predictive Maintenance in Airport Infrastructure

Sensemore offers predictive maintenance solutions to improve airport operations by preventing equipment failures and reducing…

May 13, 2024

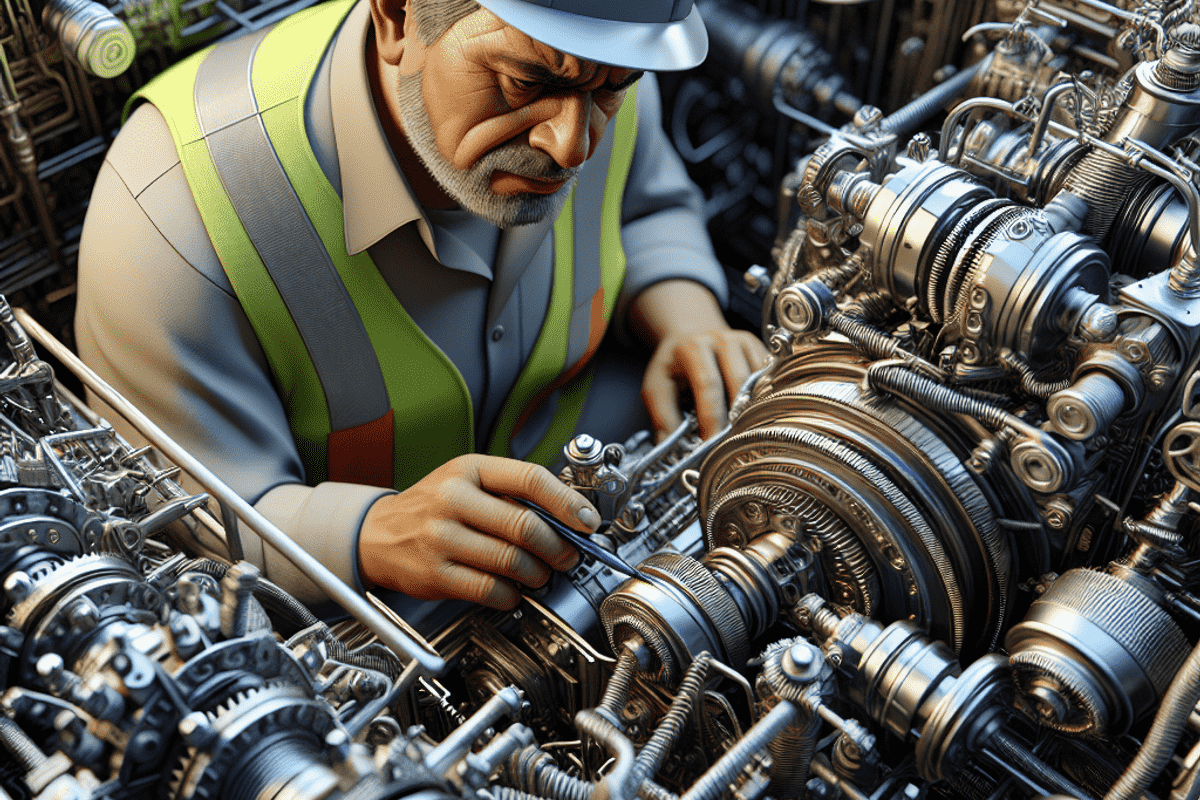

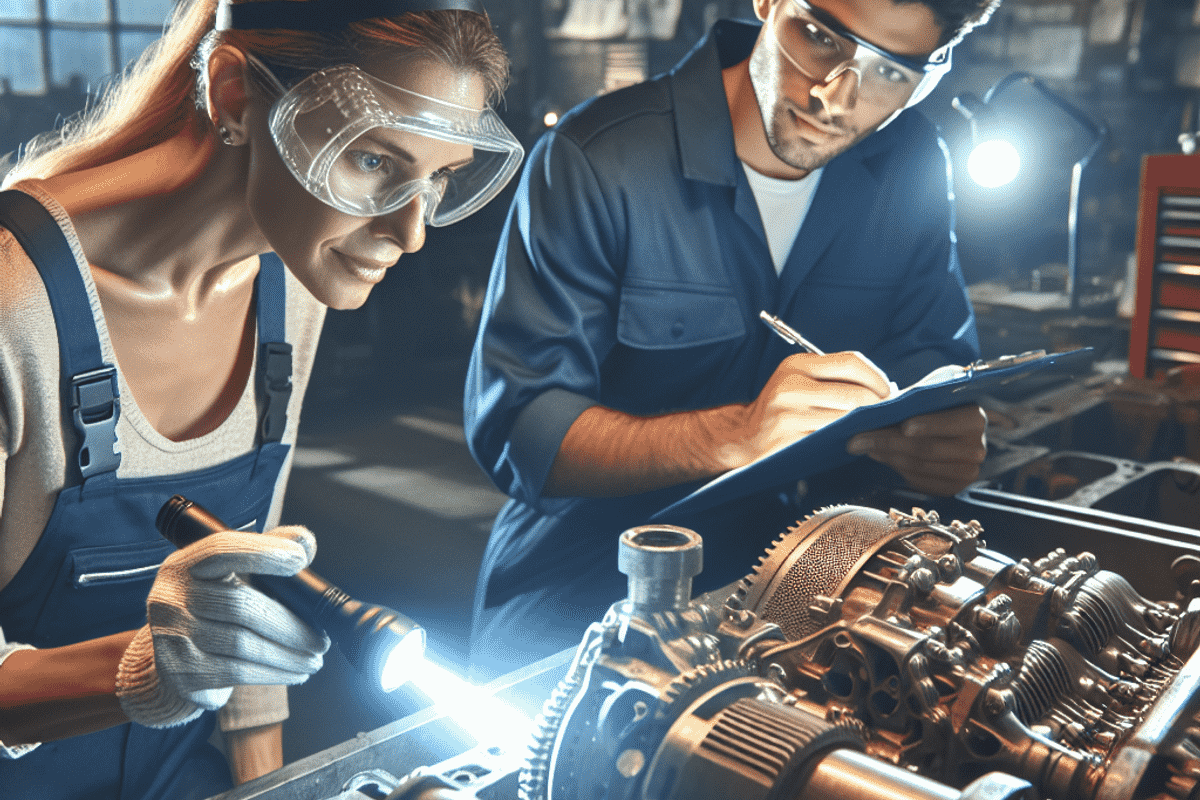

Maintenance Worker: Job Description, Skills, and Salary

Maintenance workers play a crucial role in maintaining equipment and facilities by performing inspections, preventive…

May 13, 2024

Maintenance Supervisor: Job Description Skills and Salary Range

The role of a Maintenance Supervisor encompasses overseeing the upkeep of facilities, equipment, and infrastructure.…

May 2, 2024

Unplanned Maintenance

Unplanned Maintenance refers to sudden repairs or servicing tasks necessitated by unexpected equipment failures or malfunctions.…

May 1, 2024

Exploring Equipment Failure Patterns

Equipment failure patterns illuminate the recurring causes and trends behind machinery breakdowns, offering invaluable insights…

April 30, 2024

Strategic Facility Asset Management: Planning Essentials

Crafting a Facility Asset Management Plan demands a structured approach. Begin by comprehensively assessing existing assets,…

April 30, 2024

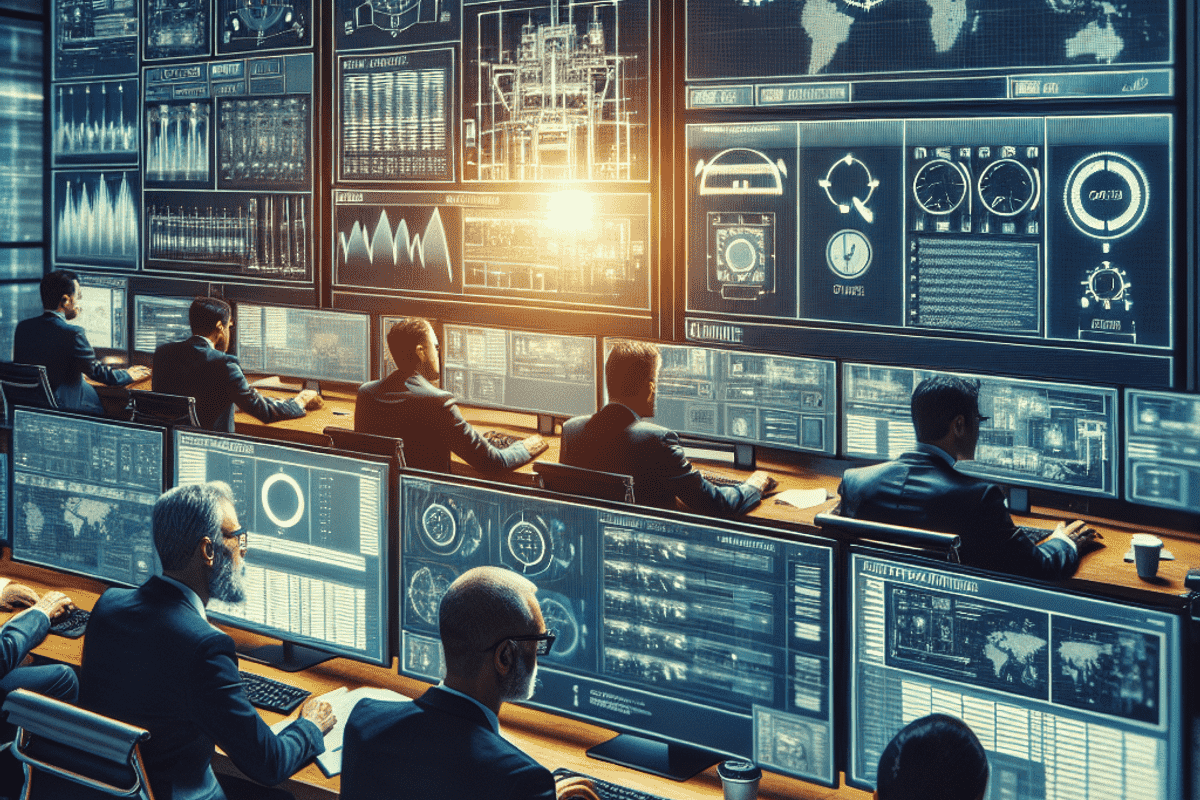

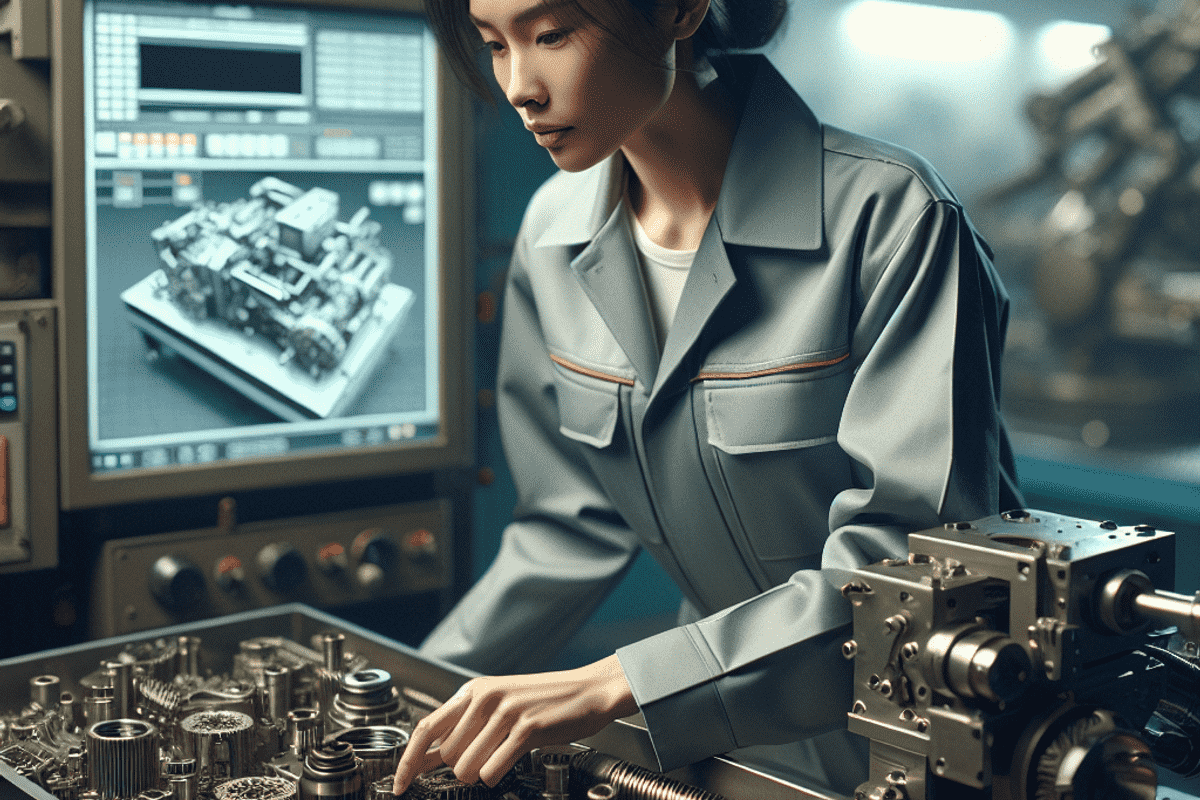

Machine Monitoring: Revolutionizing Manufacturing Efficiency

Machine monitoring is spearheading a revolution in manufacturing efficiency by offering real-time insights into production…

April 29, 2024

How to Transfer Maintenance Knowledge Efficiently?

Capturing, documenting, and transferring maintenance knowledge is essential for organizational efficiency and continuity. By…

April 29, 2024

How to Develop an Effective Maintenance Policy

Determining and crafting a maintenance policy is pivotal for ensuring operational efficiency and prolonging asset lifespan. Start…

April 29, 2024

5 Benefits of Lean Maintenance Programs

Lean Maintenance Programs offer a streamlined approach to asset management, focusing on efficiency and cost-effectiveness. By…

April 29, 2024

9 Strategies for Enhanced Safety in Your Workplace

Enhancing safety at your facility is paramount for protecting employees and assets. Implementing rigorous safety protocols,…

April 29, 2024

Optimizing Production: Calculating Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is a pivotal performance metric used to assess the efficiency of manufacturing processes.…

April 29, 2024

Reliability Engineering – Definition & Goals

Reliability Engineering, a cornerstone of modern industry, focuses on ensuring systems consistently perform their intended…

April 29, 2024

Developing an Asset Management Strategy

Crafting an effective Asset Management Strategy is paramount for organizations aiming to optimize resources and maximize returns.…

April 29, 2024

Field Failure Analysis

Field Failure Analysis is a systematic investigation process aimed at understanding the root causes of failures in products…

April 29, 2024

Improving Asset Utilization in Your Business

Enhancing asset utilization is paramount for optimizing business performance and maximizing returns. By implementing streamlined…

April 29, 2024

Planned Maintenance Percentage: Why It Matters? (PMP)

The Planned Maintenance Percentage (PMP) stands as a pivotal indicator in asset management, gauging the proportion of planned…

April 29, 2024

Industrial Maintenance Mastery: 7 Proven Tips

Mastering Industrial Preventive Maintenance is paramount for optimizing operational efficiency and minimizing downtime in…

April 29, 2024

Choosing the Right Maintenance Software Solution

Selecting the ideal maintenance software solution is pivotal for streamlined operations and cost-efficiency. Assessing factors…

April 29, 2024

What is Autonomous Maintenance?

Autonomous Maintenance empowers frontline workers with the responsibility to maintain equipment and machinery in optimal…

April 28, 2024

Failure Codes: A Comprehensive Guide

Failure codes are systematic identifiers used to categorize and analyze equipment malfunctions or breakdowns. They provide…

April 19, 2024

Reactive Maintenance: A Risky Approach to Asset Management

Reactive maintenance, though common, poses significant risks to asset management strategies. This approach addresses issues only…

April 19, 2024

Replacement Asset Value (RAV)

Replacement Asset Value (RAV) serves as a crucial metric in evaluating the worth of an asset, reflecting the cost to replace it…

April 19, 2024

FMECA for Maintenance

Failure Mode, Effects, and Criticality Analysis (FMECA) is an indispensable tool for maintenance strategies, systematically…

April 19, 2024

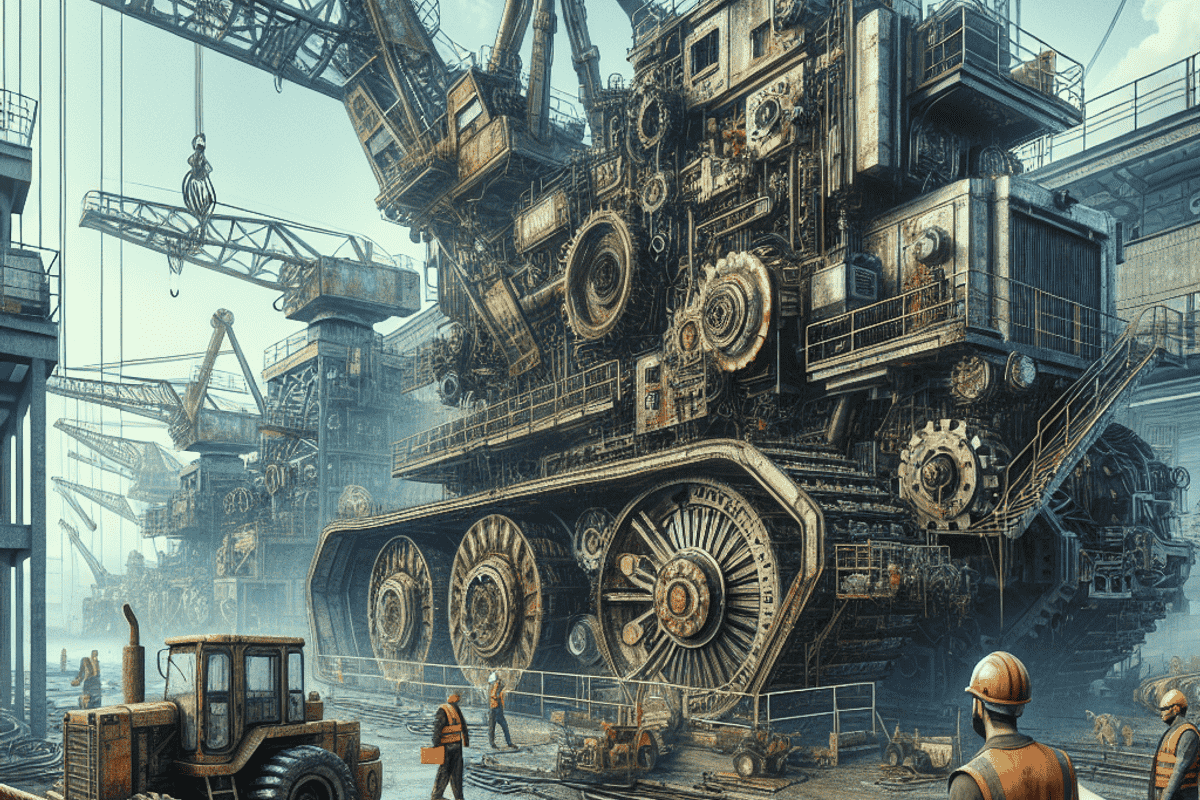

Conveyor Maintenance

Conveyor maintenance is the backbone of efficient material handling systems. Regular upkeep ensures smooth operation, prevents…

April 19, 2024

Managing and Leading Effective Toolbox Conversations

Mastering the art of toolbox conversations is essential for effective leadership and management. These discussions, held…

April 18, 2024

Improving Schedule Compliance for Maintenance Programs

Enhancing schedule compliance within maintenance programs is paramount for optimizing operational efficiency and minimizing…

April 17, 2024

Understanding Destructive Testing and Its Applications

Destructive testing is a pivotal method for evaluating the integrity and performance of materials and structures by subjecting…

April 17, 2024

CMMS vs CAFM: Key Differences

Comparing CMMS (Computerized Maintenance Management System) and CAFM (Computer-Aided Facility Management) reveals distinct…

April 17, 2024

How To Properly Perform DFMEA & PFMEA

Mastering Design Failure Mode and Effects Analysis (DFMEA) and Process Failure Mode and Effects Analysis (PFMEA) is essential for…

April 17, 2024

Wrench Time: Maximizing Maintenance Efficiency

Wrench Time, a pivotal concept in maintenance management, emphasizes maximizing productivity during maintenance activities. It…

April 17, 2024

Future of Automation in Maintenance

The future of maintenance lies in automation, revolutionizing industries with efficiency and precision. Automated systems…

April 17, 2024

Predictive Maintenance in Oil and Gas: A Comprehensive Guide

Predictive Maintenance revolutionizes oil and gas operations by leveraging data analytics to foresee equipment failures before…

April 17, 2024

Maximizing Machine Uptime: Achieving High Reliability & Availability

Maximizing machine uptime is paramount for businesses reliant on machinery. Achieving high reliability and availability involves…

April 17, 2024

Equipment Depreciation: A Comprehensive Guide

Equipment Depreciation is a fundamental aspect of asset management, encompassing the gradual reduction in value of machinery,…

April 16, 2024

What is Leak Detection and Repair (LDAR)?

Leak Detection and Repair (LDAR) is a comprehensive strategy aimed at identifying and mitigating fugitive emissions in industrial…

April 16, 2024

Mean Time Between Failure (MTBF) Explained

Mean Time Between Failure (MTBF) stands as a pivotal reliability metric, quantifying the average time a system functions before…

April 15, 2024

How to Optimize Maintenance Workflow Using CMMS?

Unlocking efficiency in maintenance management is made seamless with Computerized Maintenance Management Systems (CMMS). By…

April 15, 2024

Non-Destructive Testing (NDT): A Comprehensive Overview

Non-Destructive Testing (NDT) encompasses various techniques to assess materials' integrity without causing damage. Widely used…

April 15, 2024

What is Mean Time To Failure (MTTF)?

Mean Time To Failure (MTTF) quantifies the average lifespan of a system or component before experiencing failure. It's a crucial…

April 15, 2024

Total Effective Equipment Performance (TEEP)

Maximizing operational efficiency is a cornerstone of modern manufacturing. Total Effective Equipment Performance (TEEP)…

April 15, 2024

What Is Visual Inspection in Maintenance and Why Is It Used?

Visual inspection is a fundamental aspect of maintenance practices across various industries. It involves visually examining…

April 15, 2024

The Costs and Causes of Idle Time

Idle time in production represents more than just a lull in activity—it's a drain on resources and profitability. Whether due to…

April 15, 2024

What is Computerized Maintenance Management System (CMMS)?

A Computerized Maintenance Management System (CMMS) is a software solution designed to streamline maintenance operations. It…

April 8, 2024

MTTR: Understanding its Role in Asset Maintenance

Mean Time To Repair (MTTR) is a crucial metric in asset maintenance, measuring the average time required to restore a failed…

April 8, 2024

Improving First Time Fix Rate (FTFR)

First Time Fix Rate (FTFR) is a key indicator of maintenance efficiency, measuring the percentage of repairs successfully…

April 3, 2024

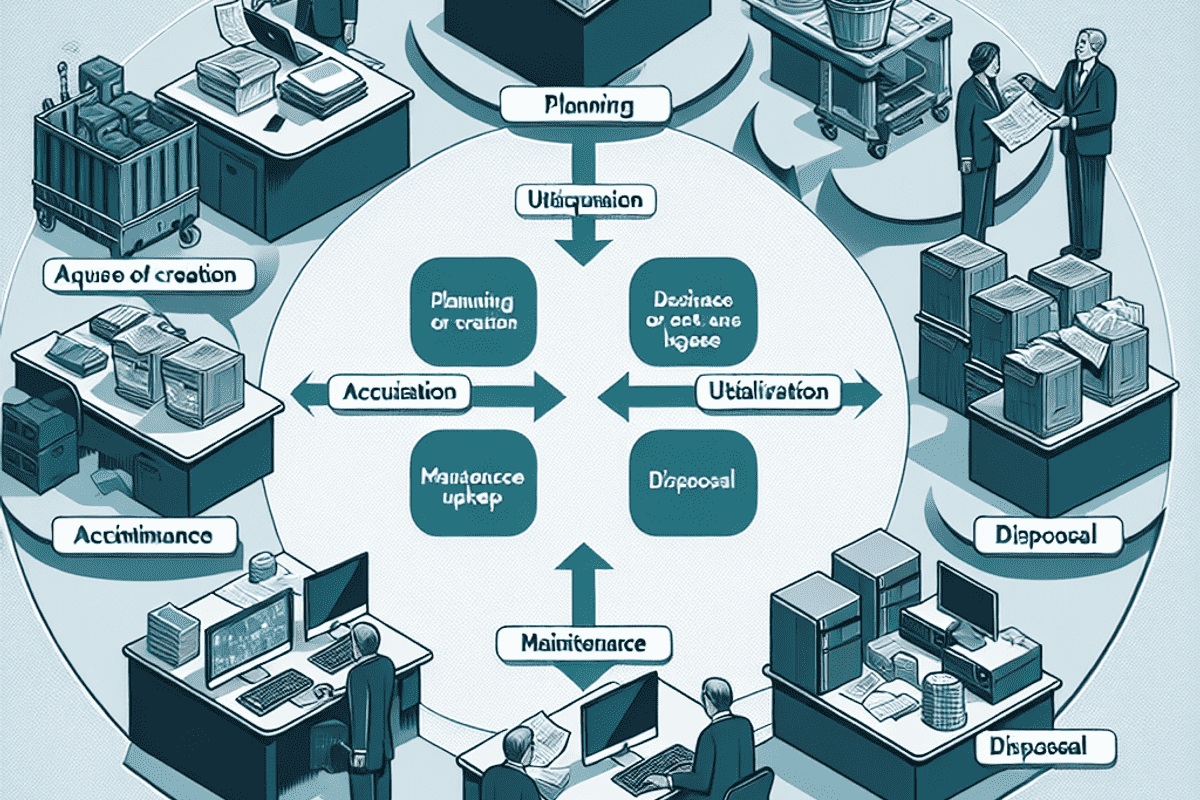

What is Asset Lifecycle? Step-by-Step

The asset lifecycle represents the journey of an asset from acquisition to disposal. It comprises several key stages: planning,…

April 3, 2024

What is Prescriptive Maintenance? Benefits and Implementation

Prescriptive maintenance is a proactive maintenance approach that leverages data analytics and machine learning to forecast…

April 2, 2024

Facility Maintenance – What is Facility Maintenance?

Facility maintenance encompasses a range of tasks aimed at ensuring the smooth operation of buildings, equipment, and systems…

April 1, 2024

Breakdown Maintenance: Types and Examples

Breakdown maintenance, also known as reactive maintenance, involves repairing assets only when they fail. It can be categorized…

April 1, 2024

Maintenance, Repair, and Overhaul (MRO)

Maintenance, Repair, and Overhaul (MRO) is a comprehensive approach to managing the upkeep of assets, machinery, and equipment.…

April 1, 2024

5 Causes of Industrial Equipment Failure

Industrial equipment failure can stem from various factors. Common causes include inadequate maintenance practices, such as…

April 1, 2024

Augmented Reality in Maintenance

Augmented Reality (AR) is revolutionizing maintenance practices by overlaying digital information onto real-world environments.…

April 1, 2024

What is Maintainability?

Asset management in maintenance involves systematic planning, tracking, and optimizing assets for peak efficiency and minimal…

March 29, 2024

Reliability-Centered Maintenance: What It Is and How It Helps

Asset management in maintenance involves systematic planning, tracking, and optimizing assets for peak efficiency and minimal…

December 21, 2023

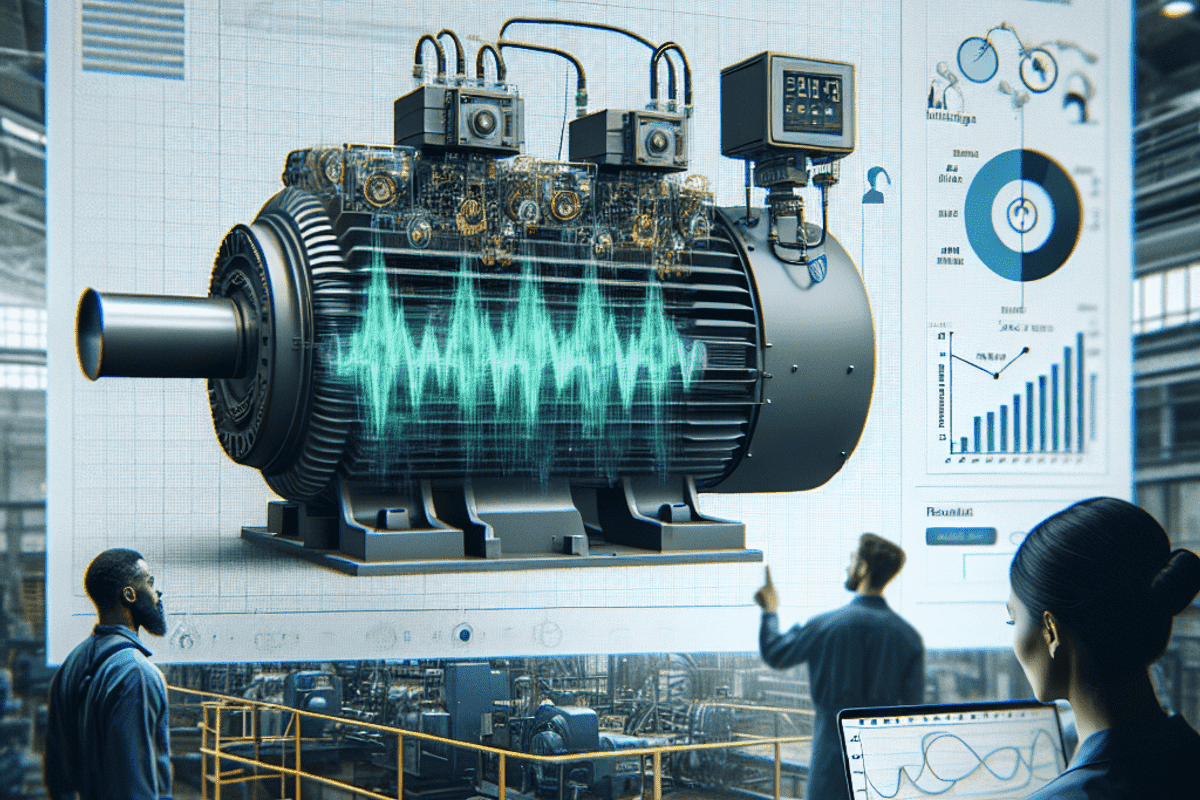

Motor Current Signature Analysis (MCSA) for Predictive Maintenance

Motor Current Signature Analysis (MCSA) is a predictive maintenance technique used to assess the health of electric motors. By…

September 8, 2023

The Evolution of Predictive Maintenance with Machine Learning and AI

Machine learning and AI have revolutionized predictive maintenance, transitioning it from reactive to proactive approaches. By…

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT unveil…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation. It helps…

July 17, 2023

What is the Difference between Maintenance and Reliability?

Maintenance ensures optimal equipment performance through proactive actions, preventing breakdowns and reducing downtime.…