Industrial fans are the unsung heroes of manufacturing facilities, working tirelessly to maintain optimal air circulation, dust collection, material transfer, temperature control, and ventilation. Despite their critical role, fan maintenance often follows reactive or calendar-based approaches that can lead to unexpected failures, energy waste, and production disruptions.

A major Fast-Moving Consumer Goods (FMCG) manufacturer recently discovered how condition-based monitoring and automated planning could revolutionize their fan maintenance strategy, delivering significant cost savings and operational improvements.

The Challenge: Traditional Fan Maintenance Falls Short

The FMCG facility operated over 100 industrial fans across multiple production lines, including large ventilation fans, cooling fans for equipment, and exhaust fans for process areas. Their traditional maintenance approach involved:

• Fixed scheduling: Cleaning fans every 3–6 months regardless of actual condition

• Reactive repairs: Addressing failures only after they occurred

• Manual inspections: Time-intensive visual checks that often missed early degradation signs

• Energy inefficiency: Dirty fans consuming 15–30% more energy than clean ones

This approach resulted in several costly problems:

• Unexpected fan failures during peak production periods

• Over-maintenance of fans in clean environments

• Under-maintenance of fans in harsh conditions

• Increased energy consumption across the facility

• Labor-intensive maintenance scheduling and execution

The Solution: Condition-Based Fan Monitoring

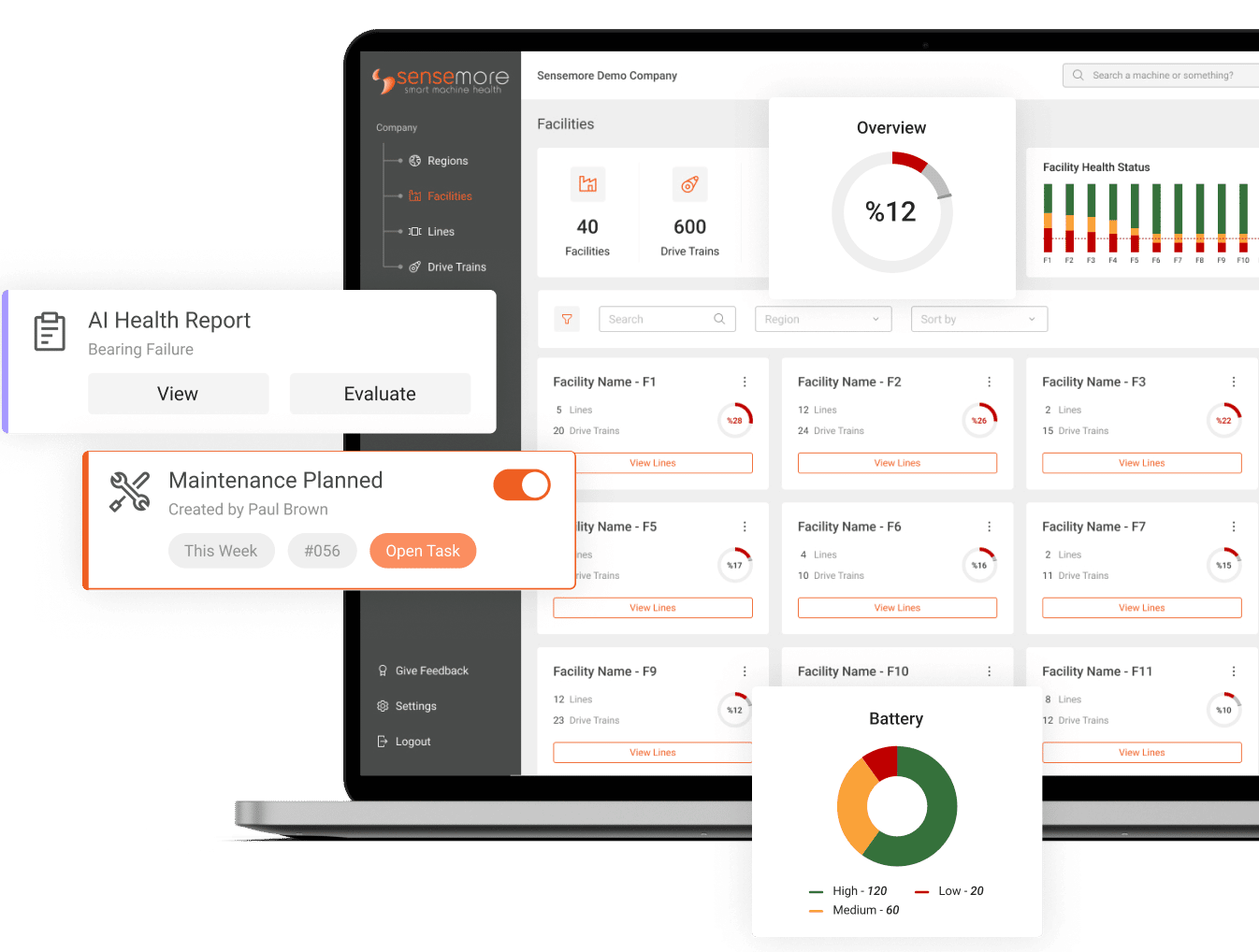

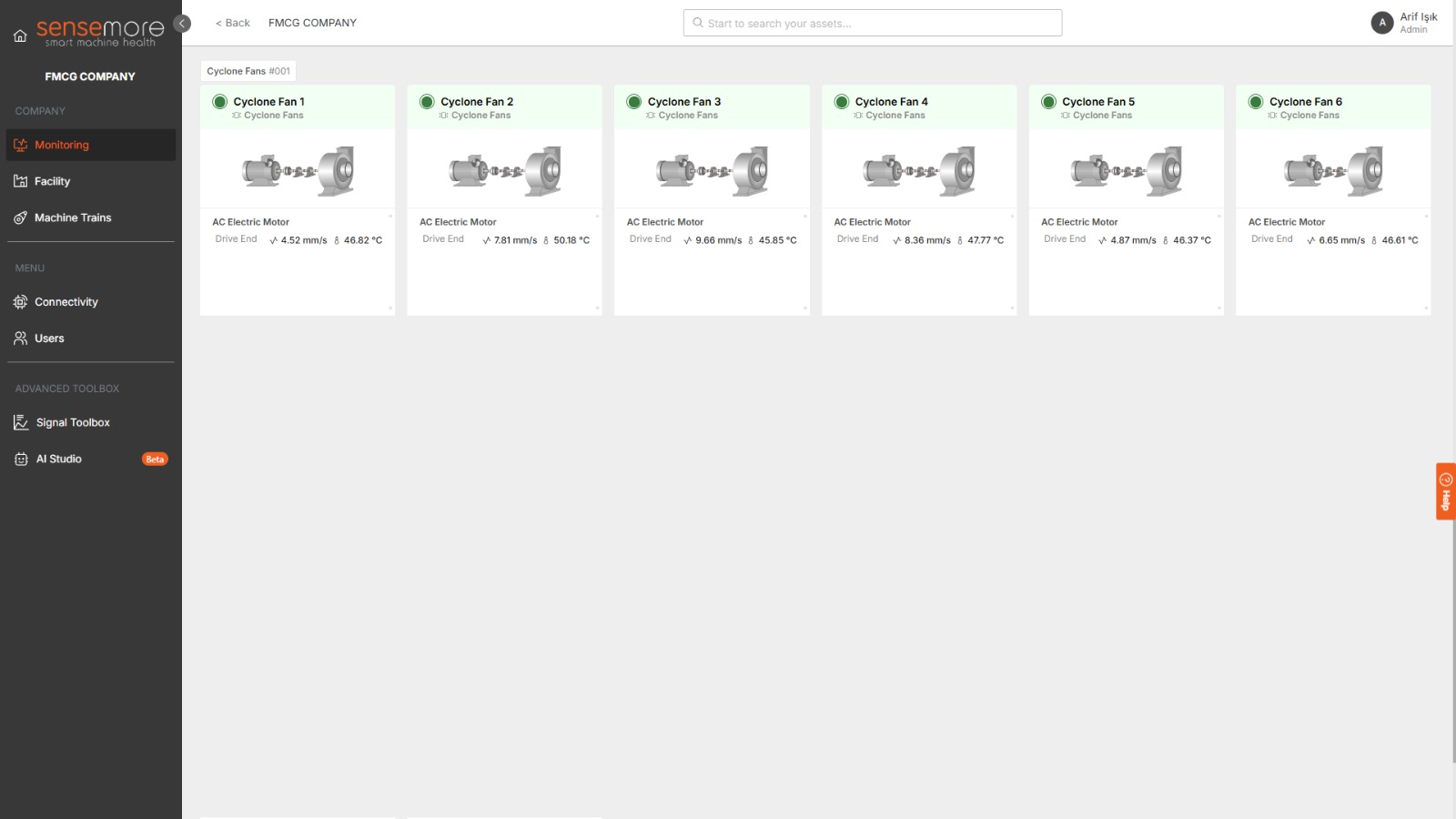

Partnering with Sensemore’s machine health platform, the company implemented a comprehensive fan monitoring system that tracks key performance indicators in real-time:

• Bearing health monitoring: Detecting early signs of bearing wear and lubrication issues

• Imbalance detection: Identifying fan blade contamination and structural problems

• Misalignment tracking: Monitoring shaft and coupling conditions

• Dust accumulation patterns: Understanding contamination rates in different facility areas

• Operating hours correlation: Linking runtime to maintenance needs

• Seasonal variations: Accounting for environmental changes affecting fan performance

Automated Planning: From Data to Action

The monitoring system doesn’t just collect data—it transforms insights into actionable maintenance plans:

• Criticality to production: Essential fans receive priority attention

• Degradation rate: Rapidly degrading fans move up the schedule

• Energy impact: High-consumption fans are prioritized for early intervention

• Maintenance window availability: Schedules align with planned production downtimes

• Optimized sequencing to minimize downtime

• Coordination with other planned maintenance tasks

Real-World Results: Measurable Impact

Operational Improvements

• 90% reduction in unexpected fan failures

• 25% decrease in total maintenance labor hours

• 60% improvement in maintenance schedule adherence

• 35% reduction in emergency callouts

Energy Savings

• 18% average reduction in fan energy consumption

• $50,000 annual savings in electricity costs

• Improved power factor across facility electrical systems

• Enhanced overall energy efficiency metrics

Cost Benefits

• 30% reduction in total fan maintenance costs

• Extended equipment lifespan by 2–3 years on average

• Reduced spare parts inventory through better planning

• Lower insurance premiums due to improved reliability

Key Success Factors

• Comprehensive sensor deployment on critical fans

• Integration with existing building management systems

• Real-time data transmission and cloud-based analytics

• Customized machine learning models and adaptive thresholds

• Continuous algorithm refinement based on maintenance outcomes

• Training maintenance teams on new data-driven approaches

• Clear communication of benefits and ROI to all stakeholders

Implementation Best Practices

• Start with critical equipment to deliver early wins

• Establish performance baselines before implementing automation

• Involve maintenance teams in algorithm development and validation

• Plan for scalability to accommodate future expansion

The Future of Industrial Fan Maintenance

• AI-powered anomaly detection for earlier fault identification

• Predictive models incorporating weather, production schedules, and supply chain variables

• Integration with digital twins for system-wide optimization

Conclusion: The Smart Maintenance Advantage

The transformation achieved by this FMCG manufacturer illustrates the powerful potential of combining IoT monitoring with automated planning. By moving beyond traditional calendar-based maintenance to a truly condition-driven approach, organizations can unlock:

• Significant cost reductions through optimized timing

• Improved reliability and longer asset lifespan

• Enhanced energy efficiency and sustainability

• Better workforce productivity and resource utilization

Ready to optimize your industrial fan maintenance? Contact Sensemore to learn how our condition monitoring solutions can transform your maintenance operations and deliver substantial cost savings.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…