Envelope analysis, a focal point in diagnostics, targets amplitude variations in vibration signals. Unlike traditional methods, it excels in detecting modulations linked to impending faults like gear damage or bearing defects. By scrutinizing signal envelopes, maintenance teams gain a magnified view of machinery health, enabling timely intervention and enhancing overall reliability.

Basics of Vibration Analysis

Vibration signals are fundamental indicators of machinery health, representing mechanical motion. These signals result from the dynamic interactions within rotating machinery components. Understanding these vibrations is crucial for assessing the condition of equipment. Vibration signals carry information about the frequency, amplitude, and phase of the mechanical oscillations, forming the basis for diagnostic analysis.

Frequency Domain Analysis

Frequency domain analysis involves decomposing vibration signals into their constituent frequencies. This process reveals the spectral content of the signal, identifying dominant frequency components. Common tools for frequency domain analysis include Fourier transforms and spectral analysis. This approach is valuable for pinpointing specific vibrational patterns associated with machinery faults, such as imbalances or misalignments.

Time Domain Analysis

Time domain analysis, in contrast, focuses on the signal’s behavior in the time dimension. It examines how the vibration signal evolves over time, providing insights into the temporal characteristics of machinery vibrations. Time domain techniques, like waveform analysis and statistical measures, offer a comprehensive understanding of the machinery’s dynamic behavior, aiding in the identification of transient events and irregularities.

Limitations of Traditional Analysis Methods

While traditional vibration analysis methods provide valuable insights, they have limitations. These methods may struggle to detect early-stage faults or subtle anomalies hidden within the signal, especially in complex industrial environments with high levels of background noise. Additionally, traditional approaches may lack the sensitivity required to identify certain fault types, necessitating the integration of more advanced techniques like envelope analysis.

Envelope Analysis Fundamentals

Definition of Envelope

The envelope in signal processing refers to a curve outlining the maximum amplitude variations of a signal. In the context of machinery diagnostics, the envelope represents a smoothed version of the vibration signal, highlighting changes in amplitude over time. It is particularly instrumental in capturing modulations within the signal associated with various faults and irregularities.

Significance in Identifying Modulations

The envelope’s primary significance lies in its ability to capture modulations within the vibration signal. Modulations are periodic variations in amplitude that often indicate the presence of faults or abnormalities in rotating machinery. Envelope analysis excels at isolating these modulations, providing a clear and distinct representation of the underlying fault signatures that might be obscured in the raw vibration signal.

Comparison with Raw Vibration Signal Analysis

Comparing envelope analysis with traditional raw vibration signal analysis underscores its superiority in fault detection. While raw signals offer a detailed but noisy representation of machinery vibrations, envelope analysis provides a refined, high-level perspective. By focusing on amplitude variations, envelope analysis effectively filters out irrelevant details, making it more sensitive to subtle changes associated with developing faults.

Advantages of Envelope Analysis

Increased Sensitivity: Envelope analysis enhances sensitivity to early-stage fault detection, making it possible to identify issues before they escalate.

Effective in Noisy Environments: In industrial settings with significant background noise, envelope analysis stands out by isolating fault-related modulations from the surrounding noise, improving signal clarity.

Fault Signature Magnification: Envelope analysis acts as a diagnostic magnifying glass, amplifying fault signatures that may be subtle or masked in the raw signal.

Proactive Maintenance: The ability to detect faults early enables proactive maintenance, reducing downtime and extending the overall lifespan of machinery.

Signal Acquisition and Preprocessing

Signal Conditioning and Amplification

Raw signals acquired from sensors often undergo signal conditioning to prepare them for analysis. Signal conditioning involves processes like amplification, analog-to-digital conversion, and filtering. Amplification increases the strength of the signal, ensuring that subtle vibrations are not overshadowed by noise. Proper signal conditioning is essential for maintaining signal integrity throughout the analysis.

Importance of Proper Sensor Placement

The placement of vibration sensors is a critical factor influencing the accuracy of data acquisition. Sensors should be strategically positioned to capture vibrations directly related to the machinery’s health. Proper sensor placement ensures that the acquired signals accurately reflect the condition of key components, such as bearings, gears, or rotating shafts. Incorrect sensor placement may lead to misleading or incomplete data.

Filtering Techniques to Enhance Envelope Extraction

Effective envelope extraction relies on pristine signals, making filtering crucial in the preprocessing stage. Filtering techniques, such as bandpass filters, help isolate specific frequency bands of interest. This step is particularly important for envelope analysis, as it enhances the extraction of modulations associated with machinery faults while minimizing interference from irrelevant frequency components or background noise.

Envelope Extraction Techniques

Hilbert Transform and its Role in Envelope Analysis

The Hilbert transform plays a central role in envelope analysis by providing a means to extract the analytic signal from a real-valued vibration signal. It achieves this by shifting the phase of the original signal by 90 degrees, producing a complex signal that encapsulates both amplitude and phase information. The envelope is then obtained by calculating the magnitude of this analytic signal, emphasizing the signal’s amplitude variations over time.

Analytic Signal Representation

The analytic signal representation encompasses both the original signal and its Hilbert transform, creating a complex signal that facilitates a comprehensive analysis of amplitude modulations. By incorporating both real and imaginary components, the analytic signal captures the instantaneous amplitude and phase characteristics of the vibration signal. This representation is pivotal for discerning modulations indicative of machinery faults.

Demodulation Techniques

Demodulation techniques are employed to isolate the low-frequency components associated with machinery faults from the high-frequency carrier signal. By demodulating the analytic signal, practitioners can extract the envelope, effectively highlighting the variations in amplitude that signify potential faults. Demodulation is particularly valuable in separating the fault-related modulations from the overall vibration signal.

Envelope Extraction Algorithms (e.g., Empirical Mode Decomposition)

Envelope extraction often involves sophisticated algorithms, with one notable approach being Empirical Mode Decomposition (EMD). EMD breaks down a complex signal into a set of intrinsic mode functions (IMFs) that represent the signal’s oscillatory components at different scales. The envelope is then extracted from these IMFs, allowing for a detailed analysis of the amplitude modulations associated with specific fault frequencies.

Fault Signatures in Envelope Analysis

Gear Tooth Damage and Modulation Effects

Gear tooth damage is a common issue in rotating machinery, and envelope analysis proves highly effective in its detection. As gears wear or suffer damage, modulations in the vibration signal occur at harmonics of the gear mesh frequency. Envelope analysis accentuates these modulations, enabling the early identification of gear tooth damage through the distinctive patterns observed in the envelope.

Bearing Defects and their Impact on the Envelope

Bearing defects, such as pitting or spalling, introduce characteristic modulations in the vibration signal. Envelope analysis amplifies these modulations, making it possible to identify the specific frequencies associated with bearing faults. By focusing on the envelope, analysts can pinpoint the early stages of bearing deterioration, facilitating timely intervention and preventing catastrophic failures.

Misalignment and its Manifestation in the Envelope

Misalignment in rotating machinery causes modulations in the vibration signal at frequencies related to the rotational speed and the misalignment itself. Envelope analysis discerns these modulations, providing a clear indication of misalignment issues. Identifying misalignment through envelope analysis allows maintenance teams to rectify the problem promptly, preventing further damage to components and optimizing machinery performance.

Other Common Faults Detected through Envelope Analysis

Imbalance: Imbalances in rotating components lead to modulations in the vibration signal, particularly at the rotational frequency. Envelope analysis enhances sensitivity to these modulations, aiding in the detection of imbalance issues.

Looseness: Loose components generate impact forces, resulting in modulations in the vibration signal. Envelope analysis helps distinguish these modulations from background noise, facilitating the early detection of loosening in machinery.

Belt or Coupling Issues: Envelope analysis is effective in detecting faults related to belts or couplings, such as slippage or wear. The modulations caused by these issues are highlighted in the envelope, allowing for targeted diagnostics.

Envelope Analysis Case Study: Bearing Failure

Failure of bearings can cause long-term downtime of the entire machine and even the production line. Since bearing failures constitute 41% of the failure modes of electric motors and fail much earlier than their estimated working life, continuous monitoring and fault prediction of bearings becomes a great necessity.

The operation of machine components always produces vibration. Bearing failures often cause changes in vibration patterns. These vibrations can be measured with sensors mounted at the right points of the machine. The measured vibration signals are digitized and processed. Through various signal analysis techniques, relevant fault signal components can be extracted and examined. In this way, bearing faults and defects can be detected and isolated.

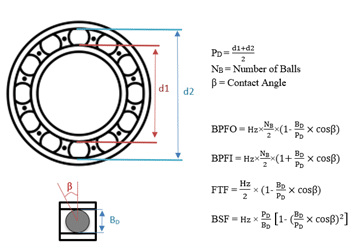

The main thing in vibration analysis is harmonic analysis. The drive frequency and its harmonics are analyzed by the sidebands of these harmonics. However, it does not coincide with the exact multiples of the drive frequency in bearing failures. Abrasions in bearings caused by reasons such as insufficient lubrication, incorrect assembly, fluting create vibrations at specific frequencies. Since we know that bearings have 4 basic mechanical parts as outer ring, ball, cage and inner ring, each part has its own specific failure frequency. These fault frequencies are BPFO (Ball Pass Frequency Outer), BSF (Ball Spin Frequency), FTF (Fundamental Train Frequency) and BPFI (Ball Pass Frequency Inner).

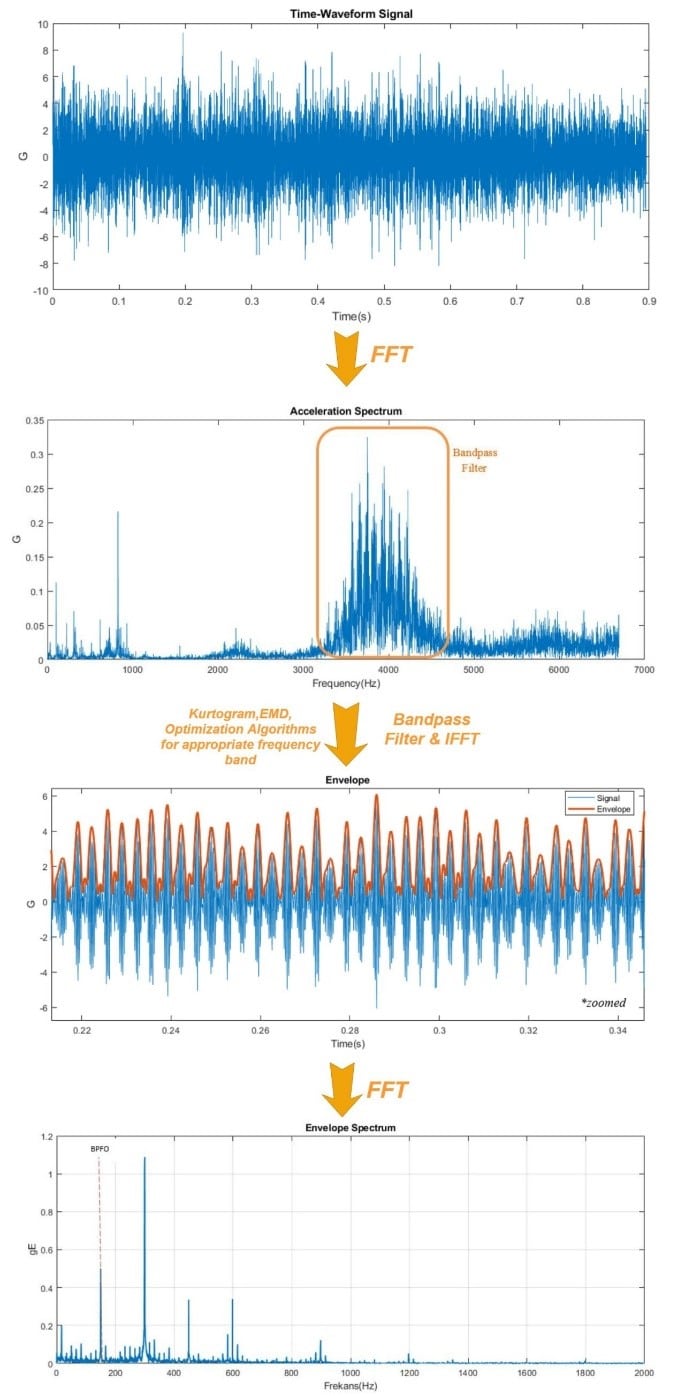

Band Selection

It is necessary to select a frequency range in the vibration spectrum where bearing failure occurs and remove all components outside the band. It is assumed that this selected frequency range relates only to bearing failures and not to other machine failures. The optimum range of the frequency band that combines the characteristic frequency of this bearing failure with the structural resonance of the systems can also be manually selected and put into the Inverse Fourier Transform, and it can also be automated with spectral kurtosis, EMD (Empirical Mode Decomposition) and other optimization algorithms.

Envelope Spectrum

The signal is modulated by selecting the band gap combining the characteristic frequency of the bearing failure with the structural resonance of the systems and taking the Inverse Fourier Transform. Then the modulated signal in time-wave form is enveloped by Hilbert Transform. The Envelope Spectrum is obtained by taking the Fourier Transform of the enveloped signal again. The predominant presence of vibrations at the bearing failure frequencies mentioned above in the Envelope Spectrum will indicate bearing failure.

Fig. 1 Failure Mode Diagram

Conclusion

Based on the evaluation of the amplitude modulation of random vibration and structural resonance, envelope analysis is one of the effective ways to detect and evaluate the condition of a bearing. Using Hilbert Transform instead of filtering and correction in envelope detection provides phase demodulation and frequency demodulation as well as amplitude demodulation for bearing fault diagnosis. Frequency demodulation paves the way for gearbox diagnostics and troubleshooting of problems caused by torsional vibrations.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…

Discover Our Products

Sensemore Predictive Maintenance Solution

If you enjoyed this blog, explore our Predictive Maintenance Solution page.