Elevate your maintenance with Sensemore’s AI-powered predictive bot for increased uptime and cost savings.

In the world of industrial maintenance, keeping equipment running smoothly and efficiently is crucial for the success of any organization. But with the increasing complexity of modern machinery, it can be difficult to keep track of all the potential problems that could occur. This is where artificial intelligence (AI) comes in. Artificial intelligence has the potential to revolutionize many aspects of our lives, and one area where it is already starting to make a significant impact is in the realm of predictive maintenance.

Predictive maintenance involves using data and analytics to predict when equipment is likely to fail, so that preventive measures can be taken to avoid downtime and costly repairs. We have already discussed the history of maintenance and answered how it has evolved to be more proactive in our other blog History and Future of Maintenance Culture – Sensemore. On the other hand, today’s trend is BOTs, to be more specific AI BOTs.

An AI-powered bot, is actually a computer program that uses artificial intelligence technologies to perform specific tasks or mimic human behaviour. These tasks can include things like responding to user input, analyzing data, and making decisions. AI bots can be integrated into various applications and even today their capability is beyond human-written programs. If you do not think you have not encountered one of them, you probably have since even voice assistants in our mobile phones are also AI bots. These bots are able to generate images based on your text description, some help for coding and the most popular of all is chatGPT after its launch in December 2022. Even though they are very new in the field, they are very popular on the internet.

Going back to the original topic, the industry lacks bots when it comes to predictive maintenance. It is obvious that offline and online analysis tools provide graphical interfaces and statistical and machine learning techniques to analyze the data and make predictions. However, the outputs sometimes remain highly technical and academical for those working in the field. In order to overcome these issues, Sensemore provides an end-to-end solution from placing Sensemore sensors on your machine to its cloud platform and presents artificial intelligence analysis on collected data.

Fig.1 Sensemore Maintenance Bot Notifications

But Sensemore is more than just a predictive maintenance tool. It is also able to perform many of the tasks traditionally carried out by human maintenance workers, such as identifying and diagnosing problems, suggesting repair options, and even scheduling maintenance activities. Additionally, Sensemore’s reliability engineers communicate directly with the user to assist them about their equipments, reports and maintenance plans. This helps to reduce the workload of maintenance teams, freeing them up to focus on more complex tasks and enabling them to be more productive and efficient. For diagnose and repair options our portal sends user friendly maintenance reports that provide the root-cause of the problem. Now with the newly developed Sensemore maintenance bot, predictive maintenance is getting more effortless and uncomplicated.

Sensemore’s bot uses developed-in-house predictive maintenance algorithms such as machine mode analysis, trend type detector, faulty detector or trend predictor. This means that our bot is specifically tailored to the needs of maintenance teams and is optimized for tasks such as analyzing sensor data and predicting equipment failures almost real-time.

For example, if a piece of equipment is operating outside of its normal parameters, a bot can be configured to send a notification to a maintenance team, alerting them to the issue and providing relevant details such as the location of the machine and potential causes of the problem. In Fig.1 the bot provides notifications for the registered customers and quick look-up analysis. If further investigation is required, it directs to Sensemore cloud platform for more sophisticated tools, analysis and reports on the measurement point.

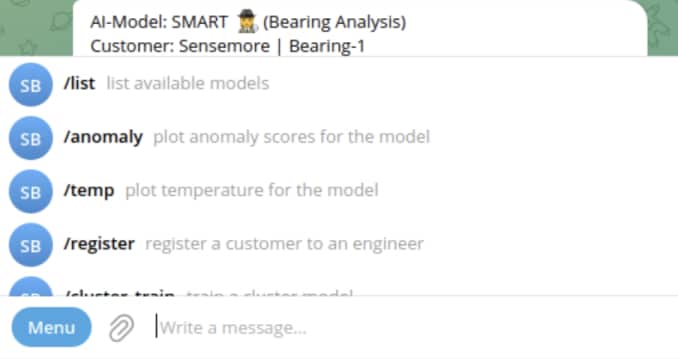

Sensemore maintenance bot is now in beta version and only available in Telegram which is a popular messaging app. Once the bot is integrated and configured, users can interact with it through Telegram’s chat interface, just as they would with any other Telegram bot. Some of the pre-defined commands can be seen in Fig.2 which helps quick reviews over mobile phones. With the help of messaging app technologies, Sensemore maintenance bot can even be send notifications over smart watches which encourages to take actions only when necessary.

Fig.2 Sensemore Maintenance Bot Available Commands

In addition to providing alerts, Sensemore bot can also be used to provide information and advice to operators and maintenance teams. For instance, the bot could be programmed to provide detailed instructions on how to perform a particular maintenance task, or to provide information about the performance and health of a particular machine. Overall, the use of bots in smart machine health platforms can greatly improve the efficiency and effectiveness of these systems. By providing real-time information and alerts, Sensemore maintenance bot can help to reduce downtime and prevent potential problems from escalating into major issues. As a result, companies that use smart machine health platforms with bots are likely to experience improved productivity and profitability.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…

Discover Our Products

Sensemore Predictive Maintenance Solution

If you enjoyed this blog, explore our Predictive Maintenance Solution page.