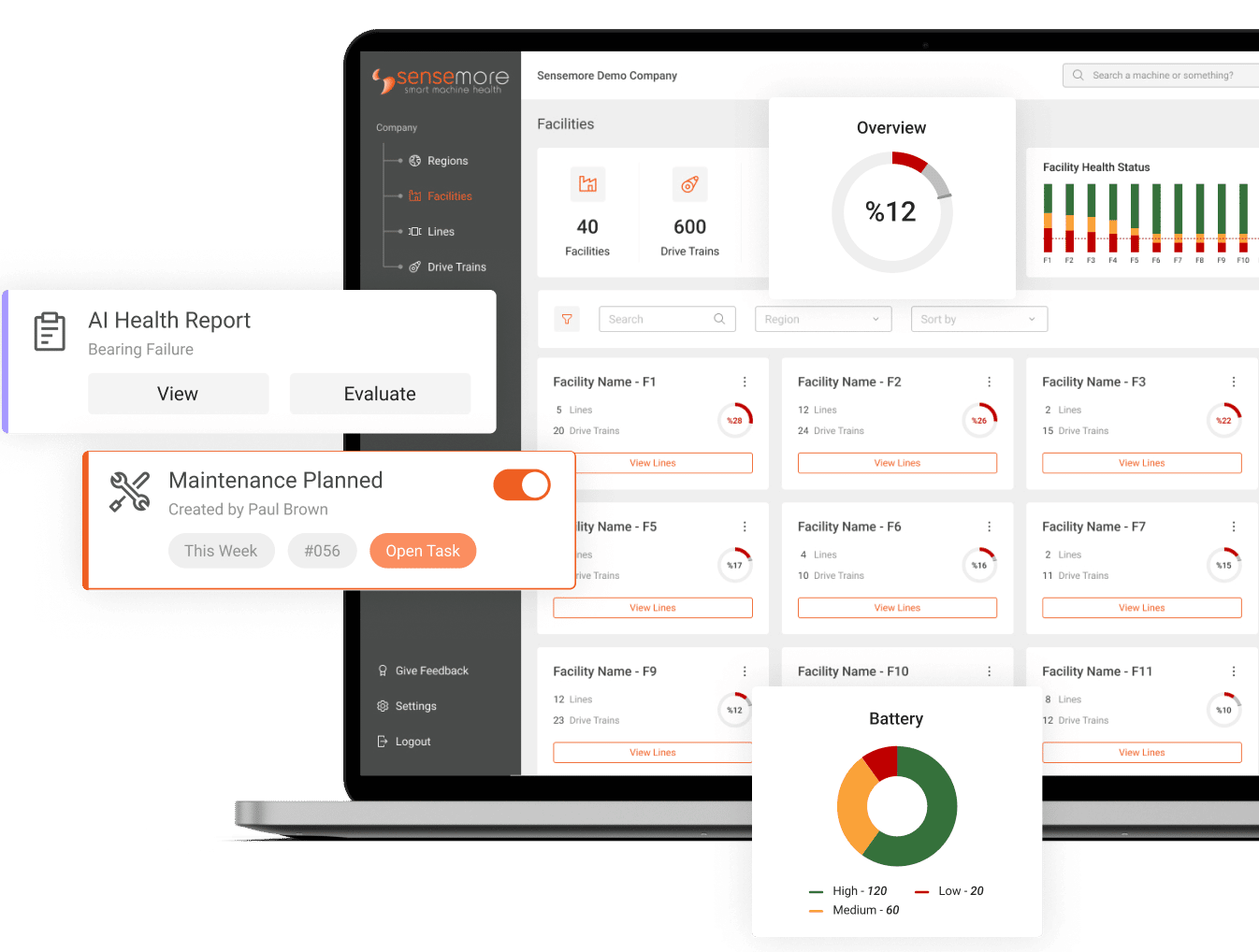

In today’s airport operations, operation teams face increasing pressure for smooth, reliable experiences for millions of passengers with an increasing demand day by day. From baggage handling systems to HVAC, elevators, and escalators, facilities rely on a network of critical systems that need to operate 24/7. At Sensemore, we aim to shape the future of airport operations by bringing advanced predictive maintenance solutions to this essential industry.

What is Predictive Maintenance?

Predictive maintenance is to use data and sensors to monitor equipment health and predict issues before failures occur. For airport operations, this means proactively maintaining baggage systems, HVAC, and other critical equipment to prevent disruptions, reduce costs, and ensure a smoother experience for passengers.

What can Predictive Maintenance Achieve in Airports?

Airports are highly complex, high-stakes environments. Any malfunction—from baggage delays to HVAC breakdowns—can significantly impact passengers, airline schedules, and airport operations as a whole. Predictive maintenance offers a strategic approach to addressing these challenges, enabling airport facilities to identify potential failures before they lead to costly downtime or disruptions.

Our advanced technology provides real-time insights into the health and performance of key airport systems. By deploying sensors and leveraging AI-driven analytics, we empower facility managers to make data-informed decisions, optimize equipment reliability, and reduce unplanned maintenance costs. This means fewer interruptions, improved energy efficiency, and an overall enhancement in service quality for passengers and airport staff alike.

The Impact of Common Failures on Airport Operations

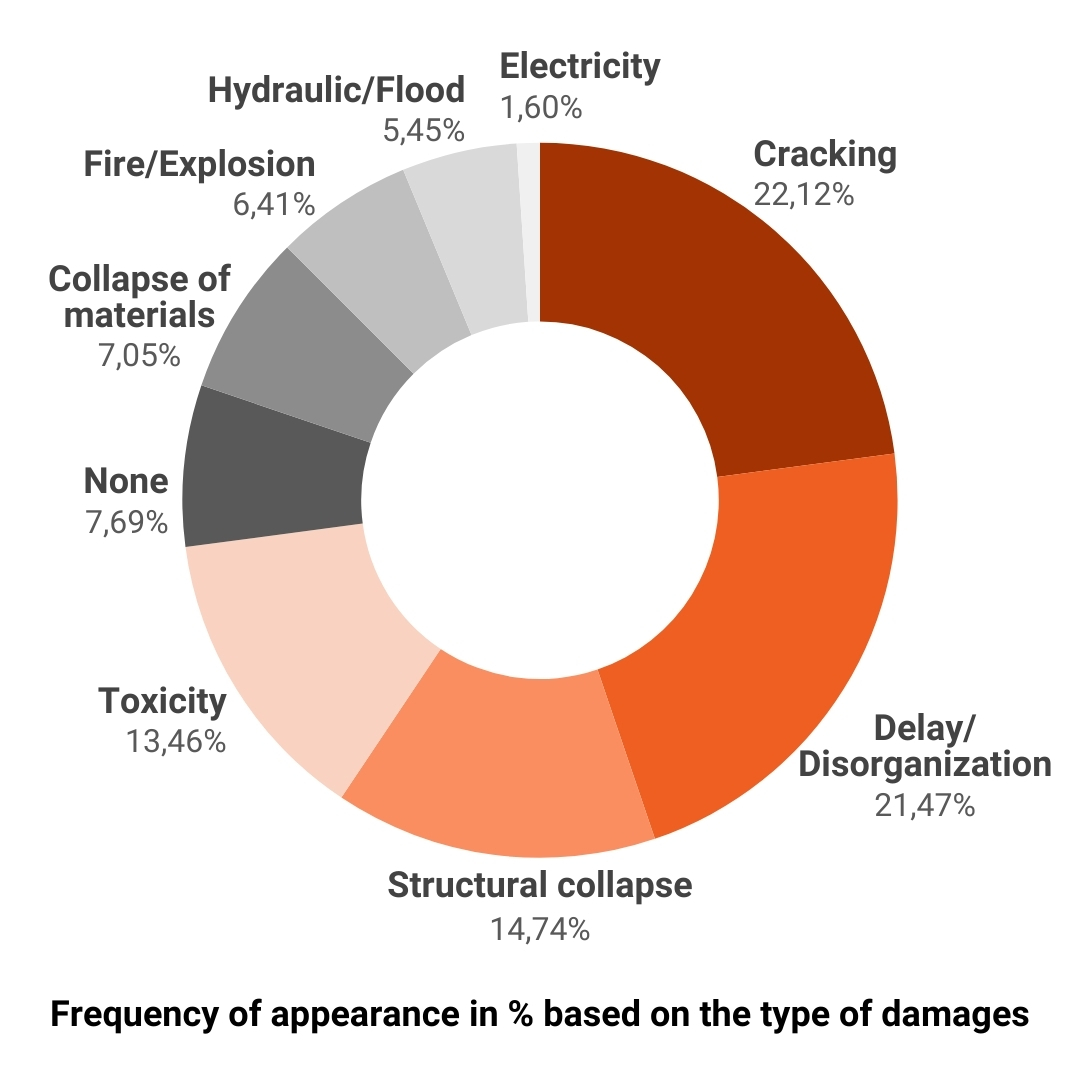

Studies on airport infrastructure indicate that cracking is the most common damage type across various case studies, appearing in around 22% of reported issues. Additionally, operational disruptions, such as delays and system disorganization, occur almost as frequently, representing roughly 21% of incidents. Structural failures, while less common, still make up about 15% of reported issues (Lahna, 2023). These statistics are significant, as most traditional aviation studies focus predominantly on aircraft-related incidents, not on infrastructure or equipment. This broader view highlights the importance of a comprehensive maintenance approach for all airport systems.

A Prevented Crack: Case Study in BHS

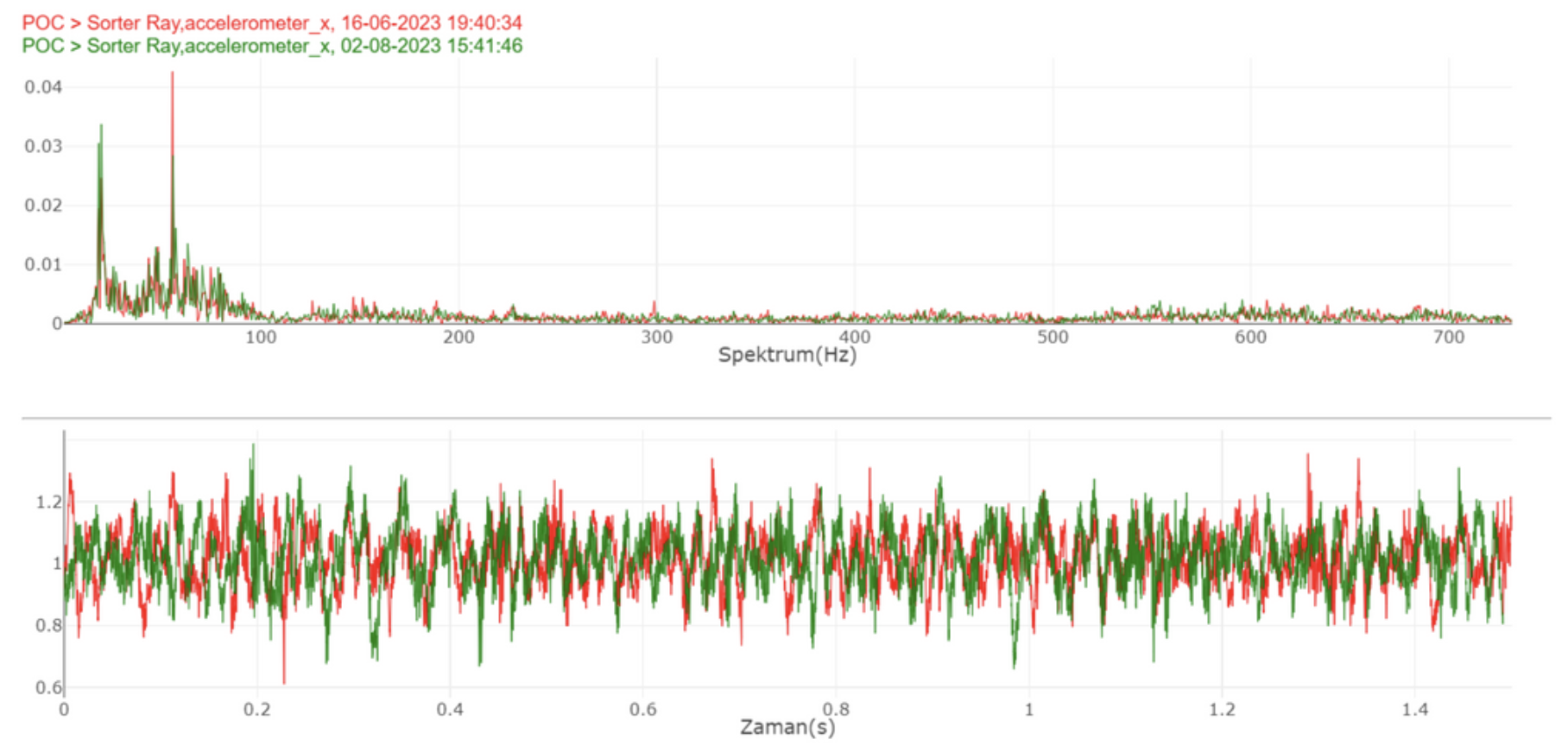

In one of our partner’s facility, Sensemore’s sensors with Sensemore Lake and Sensemore AI. The aim was to go beyond the scope of traditional vibration analysis with an experimental approach on Sorter equipment and to focus on the characteristics of structural vibrations and to diagnose possible rail damage at an early stage with the support of artificial intelligence.

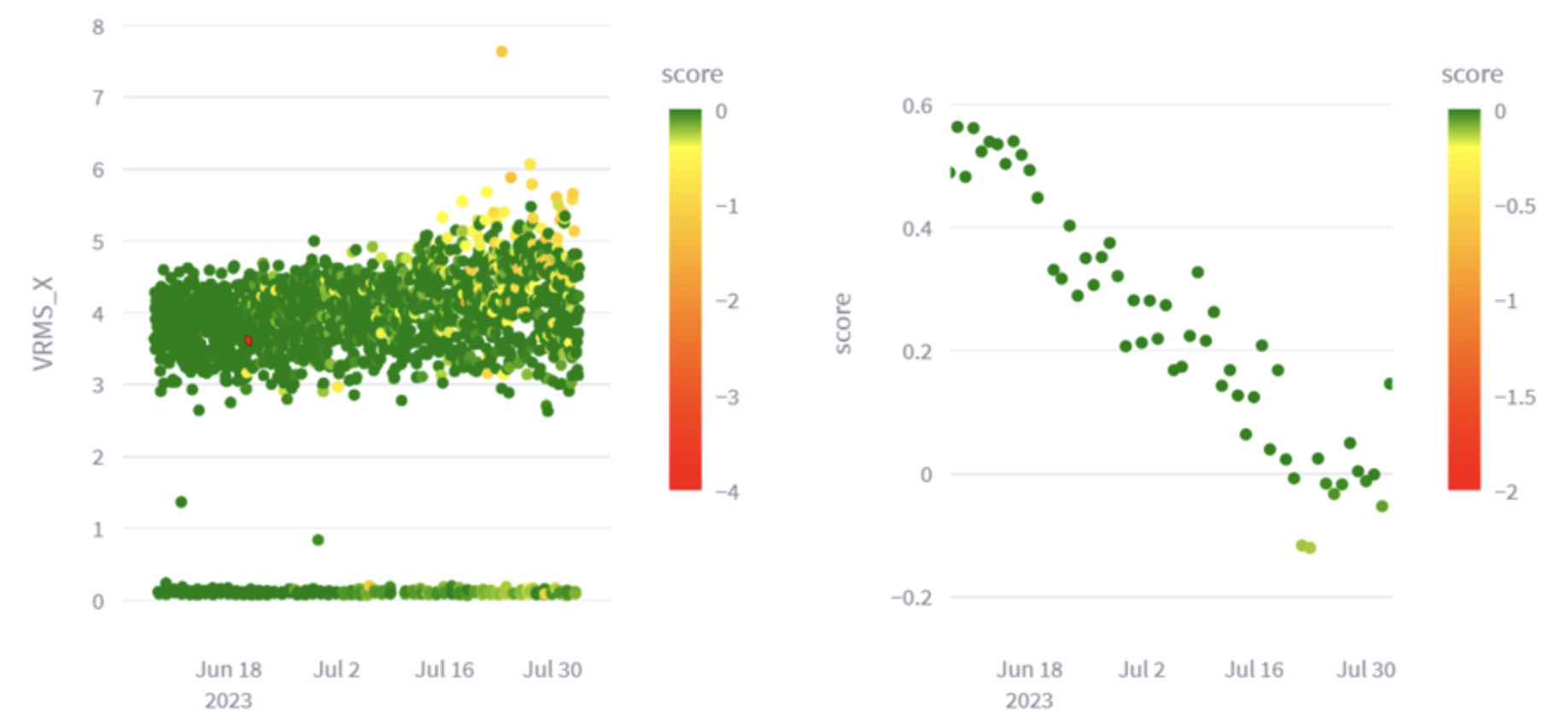

The fact that measurements taken during operation produce similar results in size and are above the determined alarm levels may give the impression that there is no change in the condition of the equipment. However, when measurements of different periods are compared on a Spectrum basis, it becomes clear that measurements that reveal similar average values have different characteristics.

Although the equipment we focus on in this study appears to continue its operation without any changes in its ordinary status control mechanisms, in fact the characteristics of the measurements are changing. The images below are analysis results created by Sensemore Artificial Intelligence Algorithms.

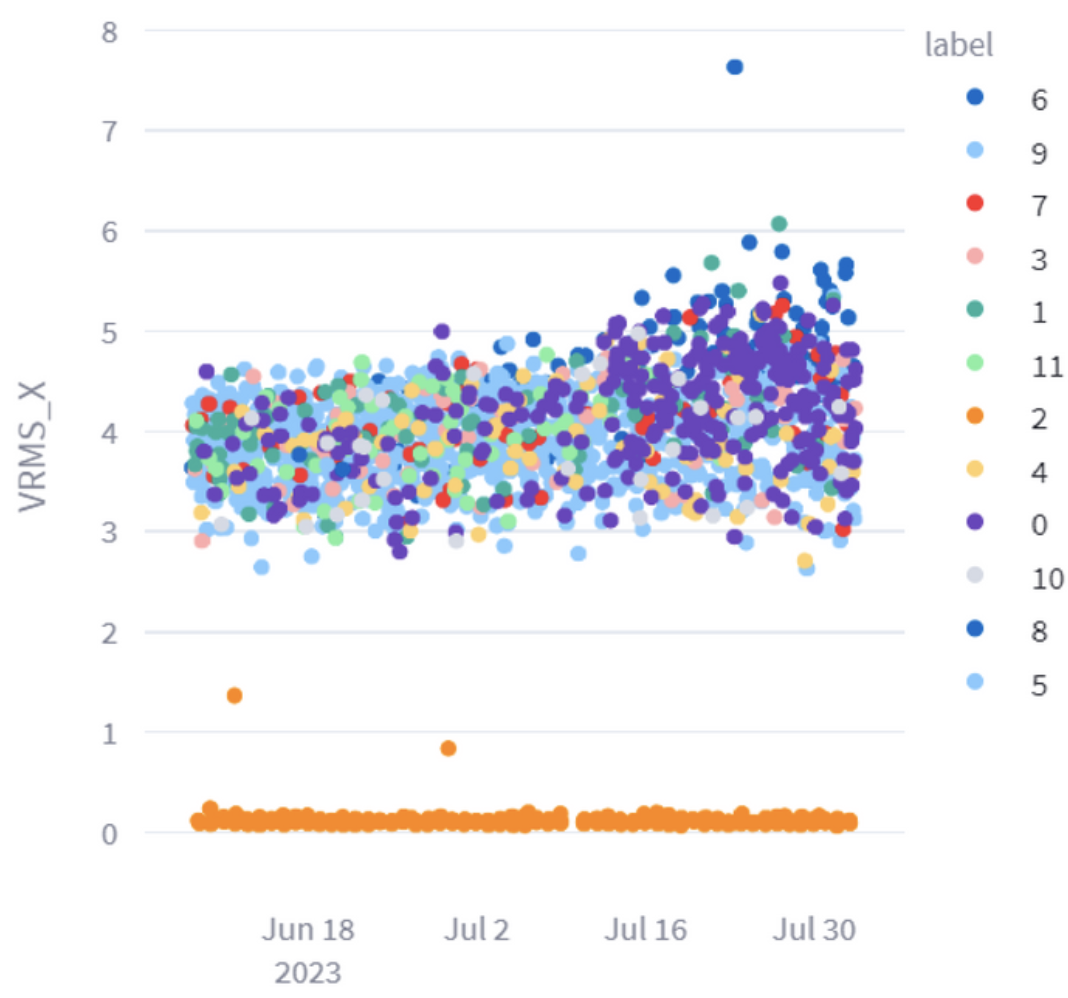

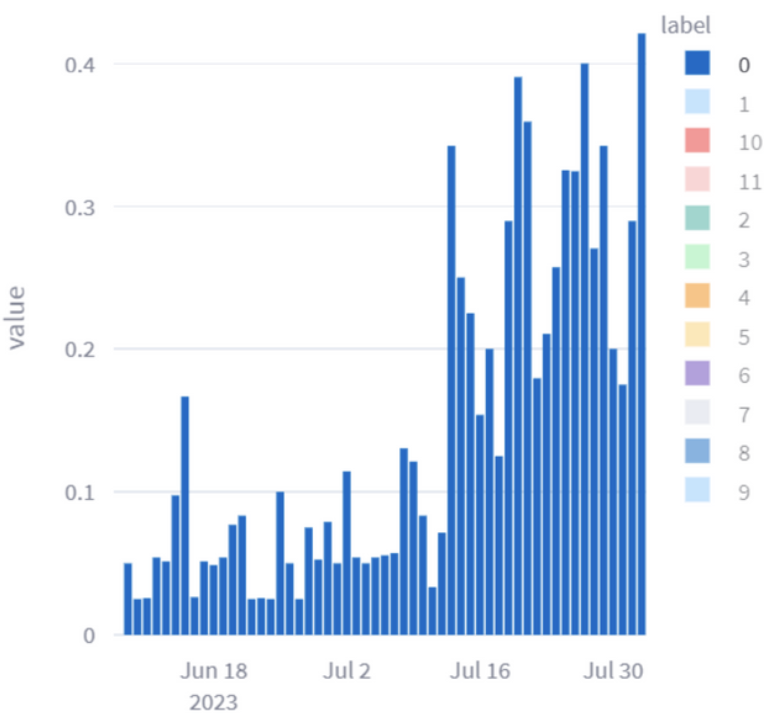

As a result of artificial intelligence analysis, we observe that the cluster labeled “0”, marked in purple, started to increase rapidly, especially after mid-July. The measurement cluster labeled “0” has increased and became the majority of the measurements received day by day and is a clear indicator that the machine has entered into a new operating mode.

In the graph above, it indicates the increasing dominance of the cluster labeled “0”, which

symbolizes abnormality and mode change. We observe that the measurements of the “0”

cluster started to increase after mid-July.

When the operation staff checked the rails, it was observed that the rails were damaged and were going to break down in a short period of time.

To sum up, this crack was prevented. Moreover, an AI-Based approach has been implemented to airport maintenance operations and gone beyond today’s traditional approach.

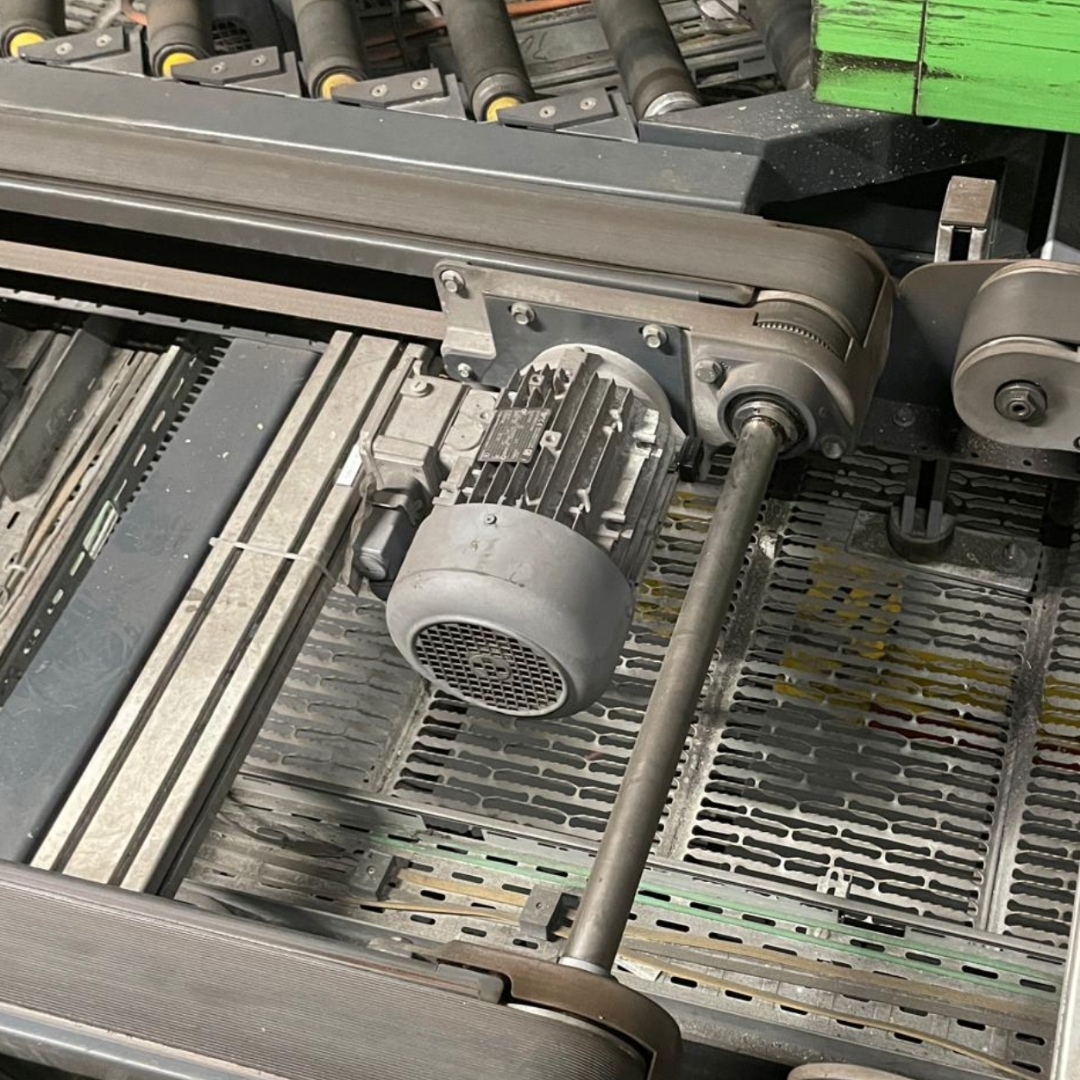

What About the Rotary?

Airports with a yearly passenger number of 1 million contain more rotary equipment than an average FMCG factory. From the HVAC to the escalators, all are powered by an electric motor and the power is transmitted via a gearbox, a belt or a coupling. This is just like a factory. Moreover, the dynamics of two businesses are pretty much the same. When a motor stops, it delays production on one side and delays the flight on the other side. Both mean loss of efficiency, effort and money. Moreover, lowers the reliability of the plant.

On the other hand, Condition Monitoring and Predictive Predictive Maintenance systems are available for these equipment. As Sensemore, we aim to provide solutions for your reliability needs.

In the airport applications; rotary equipment in escalators, elevators and HVAC are in focus. Vibration monitoring in these equipment provides the best results for reliability but variable-speed drives are also required to detect the speed and load of the machines, i.e. a multi variable monitoring. For this purpose, we use Sensemore Wired Pro and Infinity Pro which provides 3-axis vibration, 3-axis magnetic field and temperature data for these applications. But collecting data is not the end, the data must be processed to give the insights and preferably be used for decision-making and help teams to work more efficiently. Sensemore Platform covers all these benefits and makes the operation more reliable.

What has been Achieved?

Enhanced Reliability and Safety

Predictive maintenance helps airports proactively address equipment health. This leads to more reliable operations across critical areas, from baggage handling to escalators and HVAC, reducing the likelihood of breakdowns that could compromise passenger safety and comfort.

Cost Efficiency

Unplanned maintenance and downtime can be costly. Predictive maintenance enables airports to move from reactive repairs to strategic, condition-based servicing, maximizing the lifecycle of equipment and minimizing labor and part replacement costs.

Improved Energy Efficiency

Efficient systems use less energy. Predictive maintenance can identify equipment operating inefficiently, allowing airport staff to make adjustments that reduce energy consumption and environmental impact.

Enhanced Passenger Experience

Minimizing disruptions enhances the overall airport experience for passengers. Smooth operations mean shorter wait times, more predictable schedules, and a more comfortable environment, all of which contribute to customer satisfaction.

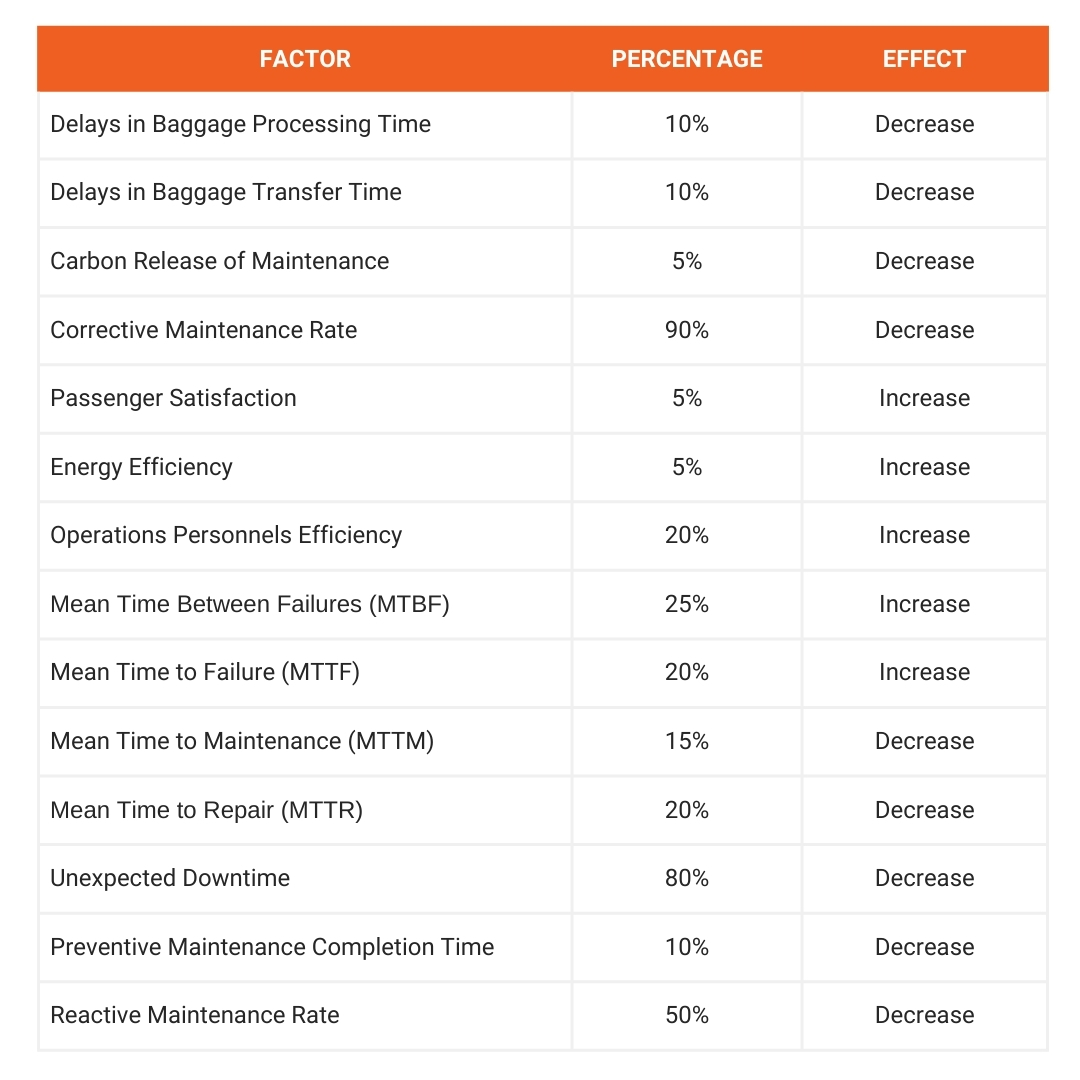

A Foresight of Gains in Numbers

Shaping the Future of Airport Operations

As the aviation industry continues to evolve, we see a future where airports worldwide adopt predictive maintenance as a standard practice. While the industry is focused on Industry 4.0, the aviation industry is also in a new age. As said by Alan Newbold, a Board Member of British Aviation Group;

It is now time for airport executives to take a more systematic, methodical approach to digital transformation to better navigate the challenges and opportunities the industry will present

Newbold, 2023

As Sensemore, we are dedicated to this vision by pioneering smarter, more efficient solutions. We aim to be the only partner of airport operations in predictive maintenance and every passenger can enjoy safe and reliable travel, when the airport personnel are on board.

To get on board with Sensemore in the way of digitalization, contact us via hello@sensemore.io or arrange a meeting with our experts via calendly.com/canaksu.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…