Asset management is a comprehensive approach that encompasses the entire lifecycle of assets, from acquisition to disposal. It embodies a strategic and systematic process, aimed at delivering value by managing assets efficiently and effectively. The essence of asset management lies in its capacity to balance performance, cost, risk, and opportunities in relation to the organization’s overarching objectives. In parallel, asset maintenance management focuses on specific strategies and practices for protecting and preserving physical assets. This is crucial for extending the lifespan of assets and ensuring they perform at their best. A strong asset maintenance strategy, including predictive maintenance and preventive maintenance tasks, is essential for enhancing asset value, minimizing operational disruptions, and reducing expenses.

Developing an effective asset maintenance management plan involves integrating maintenance strategies into an overall asset management system. This plan should include a comprehensive approach to facility maintenance, highlighting key assets and prioritizing maintenance activities based on their importance. By monitoring asset performance and leveraging technology for effective asset management, organizations can streamline processes and make informed decisions regarding maintenance activities.

The relationship between asset management and maintenance practices is key to optimizing an organization’s resources. An effective asset maintenance management plan not only extends the lifespan of assets but also minimizes downtime and improves overall operational efficiency. By selecting appropriate maintenance strategies for different asset types and establishing effective asset performance monitoring practices, organizations can ensure that their assets are well-maintained throughout their lifecycle.

The relationship between asset management and maintenance practices is key to optimizing an organization’s resources:

- Asset Management: Takes a holistic view that integrates efforts across departments to maximize the value of the asset portfolio.

- Maintenance Management: Focuses on efficiently maintaining assets to prevent failures and prolong their usefulness.

Understanding the difference between these two areas is important because:

- Well-maintained assets are less likely to break down, leading to fewer operational disruptions.

- Assets that receive proper maintenance tend to last longer, reducing the need for frequent replacements or major repairs.

To achieve effective asset maintenance, it is essential to establish a proactive strategy that not only prevents equipment failures but also aligns with broader business goals. This approach supports continuous operational excellence and responsible financial management.

The Key Components of Comprehensive Asset Management

1. Asset Identification and Location

Asset management starts with accurately identifying and locating assets, which is essential for effective tracking and maintenance. Here are the key elements:

Comprehensive Asset Registry

Establishing a complete inventory that records every asset within an organization is vital. This registry should include pertinent details such as serial numbers, model specifications, and acquisition dates.

Challenges in Asset Diversity

Organizations often struggle with a wide range of assets, including machinery, vehicles, IT equipment, and infrastructure. The different types of assets make it more challenging to identify them, requiring customized approaches to categorize and manage each asset class.

Geo-Tagging and GIS Integration

For assets spread across multiple locations or those that can move around, using geographic information systems (GIS) and global positioning systems (GPS) can help track their real-time location. Geo-tagging assets ensures they can be quickly found for inspection, maintenance, or during an audit.

Barcoding and RFID Technology

Using barcodes or radio-frequency identification (RFID) tags makes it easier to locate assets. Scanning these identifiers can provide immediate access to an asset’s history, current status, and other critical data.

Inter-departmental Coordination

Effective asset identification and location require coordination between various departments such as finance, operations, and maintenance. Each department may interact differently with assets, so there needs to be a unified system to manage this information centrally.

Organizations that excel in identifying and pinpointing their assets set the stage for successful asset management. By overcoming these challenges through strategic use of technology and inter-departmental collaboration, businesses can ensure that their assets are accounted for and accessible when needed. This meticulous approach facilitates scheduled maintenance activities while allowing swift response to any emerging issues affecting asset performance or availability.

The next step after establishing robust identification and location practices involves assessing the condition of these assets—an equally crucial component that supports proactive maintenance strategies.

2. Asset Condition Assessment

Evaluating the condition of assets is a crucial step in asset management. It involves using both traditional and advanced methods to understand their current state and predict how they will perform in the future. Here are some common approaches used for this purpose:

Visual Inspections

Visual inspections are essential for initial assessments. Trained personnel manually check the assets to look for signs of wear, corrosion, or other types of damage that could affect their performance.

Automated Monitoring Systems

Automated monitoring systems play a significant role in asset condition assessment. These systems continuously monitor the performance parameters of assets and provide real-time data. This data helps identify any unusual behavior that could indicate potential issues with the assets.

The use of a SCADA (Supervisory Control and Data Acquisition) system takes asset condition assessment to a whole new level. SCADA systems offer extensive monitoring capabilities for different types of assets, enabling:

- Real-time data collection from remote sensors,

- In-depth analysis of operational data,

- Early detection of abnormalities before they turn into major failures.

By making use of SCADA technology, organizations can move away from reactive maintenance methods and adopt preventive strategies instead. This shift leads to improved asset reliability, longer service life, and optimized maintenance costs.

Proactive failure detection through SCADA is critical in reducing downtime and ensuring uninterrupted operation within specified performance standards.

3. Asset Specification and Performance Standards

Asset specification is a crucial part of effective asset management. It involves understanding the technical details, operating conditions, and performance requirements of each asset. By clearly defining these characteristics, organizations can establish what they expect from an asset in specific situations.

Here’s why asset specification matters:

- Setting Performance Expectations: Knowing the specifications helps organizations set realistic performance standards for their assets. These standards act as a reference point for comparing an asset’s actual performance with its expected performance. For example, if a machine is designed to produce 100 units per hour, that becomes its performance benchmark. Any deviation from this benchmark could indicate a need for maintenance or inspection.

- Defining Operating Limits: Asset specifications also include defining clear boundaries for how an asset should be operated. These boundaries indicate the safe limits within which an asset can function without any risk of damage or failure. For instance, an engine might have a specified temperature range within which it should operate; going beyond this range could lead to overheating and potential failure.

By combining detailed asset specifications with well-defined performance standards and operating boundaries, organizations can take a proactive approach to managing their assets. This approach helps in:

- Maintaining asset integrity

- Mitigating risks

- Extending the lifespan of assets

All of these factors contribute to improving overall operational effectiveness and efficiency.

4. Cost Considerations in Asset Management

Cost plays a crucial role in asset management, affecting both the immediate usability and long-term viability of assets. That’s why it’s important to have strategies in place to optimize the costs associated with the entire life cycle of an asset.

What is Life Cycle Costing?

One method that organizations use to manage costs effectively is life cycle costing. This technique involves evaluating the total cost of an asset over its entire lifespan – from when it’s first acquired to when it’s eventually disposed of. By doing so, organizations can get a comprehensive understanding of all the expenses related to an asset, including both direct and indirect costs.

Direct Costs

Direct costs are those that are directly tied to the purchase and maintenance of an asset. They include things like:

- The initial purchase price

- The cost of regular maintenance and repairs

- Any fees associated with warranties or insurance

Indirect Costs

Indirect costs, on the other hand, are those that aren’t as obvious but can still have a significant impact on an organization’s operations. Some examples of indirect costs include:

- Downtime or lost productivity due to equipment breakdowns or maintenance activities

- The cost of training employees on how to use and maintain specific assets

- Any potential fines or penalties that could be incurred if assets aren’t properly maintained or replaced when necessary

Benefits of Life Cycle Costing

Implementing life cycle costing can provide valuable insights for organizations looking to make informed decisions about their assets. Some potential benefits include:

Understanding the True Cost of Ownership

- By taking into account both direct and indirect costs, organizations can get a more accurate picture of how much it actually costs to own and operate a particular asset over its lifetime. This information can be especially useful when comparing different options or deciding whether to repair or replace an existing asset.

Identifying Cost-Effective Maintenance Strategies

- Through life cycle costing, organizations can also identify which maintenance strategies are the most cost-effective in the long run. For example, while it might be cheaper to perform reactive maintenance (i.e., only fixing something when it breaks), this approach could lead to higher overall costs due to increased downtime and more extensive repairs. On the other hand, investing in proactive maintenance (i.e., regularly inspecting and servicing assets to prevent breakdowns) could help minimize unexpected expenses and maximize asset uptime.

Making Informed Decisions on Repair vs. Replacement

- Another key advantage of life cycle costing is that it enables organizations to make data-driven decisions when it comes to repairing or replacing assets. Instead of relying solely on intuition or past experiences, decision-makers can use quantitative information about an asset’s expected remaining life and projected costs to determine the most financially sound course of action.

Example Scenario

Let’s say a manufacturing company has a machine that frequently breaks down. Each time it malfunctions, they have to spend money on repairs and experience downtime while waiting for it to be fixed. After conducting a life cycle cost analysis, they discover that these ongoing issues are causing the total cost of owning the machine to exceed its initial purchase price.

In this case, the analysis might indicate that it would actually be more cost-effective for the company to replace the machine altogether rather than continue pouring money into temporary fixes. While purchasing a new machine would involve a higher upfront investment, it could lead to significant savings in the long run by reducing repair expenses and minimizing production disruptions.

The Role of Cost in Decision-Making

As you can see from this example, considering cost implications is critical when making decisions related to asset identification, location, condition assessment, and specification. By taking a proactive approach and factoring in both direct and indirect costs throughout an asset’s life cycle, organizations can:

- Minimize unnecessary expenditures

- Allocate resources more efficiently

- Extend the useful life of assets

- Enhance overall operational performance

Ultimately, this can result in substantial cost savings and improved efficiency in an organization’s asset management practices.

The Role of Different Maintenance Strategies in Asset Management

Asset management involves various strategies to ensure assets are maintained effectively, each with unique approaches and benefits. Here we explore the different maintenance strategies and how they contribute to asset management.

Corrective Maintenance

Corrective maintenance is a reactive approach that involves repairing or replacing assets after a failure has occurred. Here’s what you need to know:

- Reaction to Failures: Action is taken once an issue arises, which can lead to unexpected downtime.

- Cost Implications: Potentially higher costs due to emergency repairs and interruption to operations.

- Disruptive Nature: Unplanned work can disrupt regular workflows and production schedules.

Preventive Maintenance

Preventive maintenance is a systematic and scheduled approach aimed at preventing failures before they occur. It typically involves:

- Regular Inspections: Scheduled checks to identify issues before they escalate.

- Routine Maintenance Tasks: Activities such as lubrication, adjustments, and parts replacement performed at set intervals.

- Lifespan Prolongation: Helps in extending the life expectancy of assets by minimizing wear and tear.

Predictive Maintenance

Predictive maintenance uses technology and data analytics to anticipate maintenance needs. This strategy includes:

- Advanced Monitoring: Utilizes sensors and advanced diagnostics to monitor asset conditions.

- Data Analysis: Employs algorithms to predict potential failures based on real-time data.

- Optimized Performance: Focuses on maintaining assets at peak functionality, reducing unnecessary interventions.

Organizations choose maintenance strategies by considering asset criticality and failure characteristics. For high-value assets where failures result in significant operational disruptions, predictive maintenance may be preferred. On the other hand, for non-critical assets or those with lower downtime costs, preventive or corrective strategies might be more cost-effective.

Effective asset management requires a balanced use of these strategies tailored to the specific needs of the organization’s asset portfolio. By understanding each strategy’s role in maintaining asset health, businesses can optimize their operations for reliability and efficiency without compromising on performance or safety.

Scope of Asset Management, Physical and Non-Physical Assets

The scope of asset management is expansive, covering a diverse range of assets that contribute to an organization’s functionality and value creation. This includes both physical assets, such as machinery, buildings, and vehicles, and non-physical or intangible assets, such as software, patents, and brand reputation.

Physical Assets:

Machinery and Equipment: Management of production machinery, tools, and equipment critical for manufacturing processes.

Facilities: Oversight of buildings, utilities, and infrastructure to ensure their operational integrity and longevity.

Fleet: Maintenance of vehicles and transportation assets to sustain their performance and safety standards.

Non-Physical Assets:

Technology and Software: Management of software applications, IT infrastructure, and technological assets.

Intellectual Property: Preservation and exploitation of patents, trademarks, and copyrights to maximize their value.

Human Capital: Consideration of workforce skills, training, and knowledge as crucial assets contributing to organizational success.

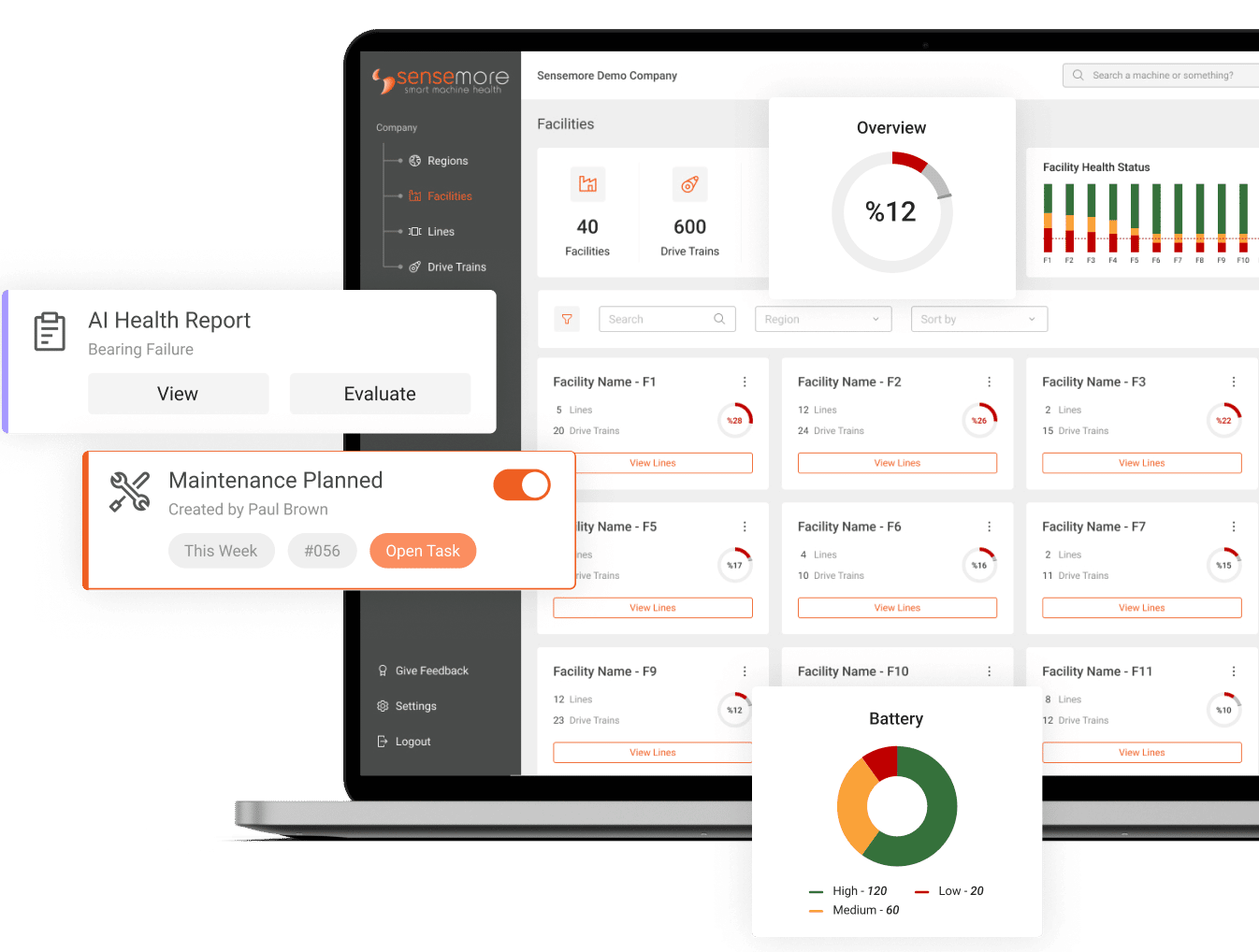

Harnessing Technology for Effective Asset Management and Maintenance

In the world of asset management, using a Computerized Maintenance Management System (CMMS) is crucial. A CMMS acts as a central hub, significantly improving the efficiency of maintenance operations by:

- Bringing together important asset information for easy access and analysis

- Automating regular tasks, scheduling maintenance work, and creating work orders

- Making inventory management of spare parts and tools easier

- Providing detailed records for audits and compliance reporting

By integrating a CMMS into their processes, organizations can get real-time insights into how their assets are performing and what maintenance they require.

The Power of Predictive Maintenance

Another technological innovation that’s transforming asset management is predictive maintenance. This approach uses machine health data to predict potential problems before they occur. Here’s how it works:

- IoT sensors are used to continuously monitor equipment conditions.

- Advanced analytics are applied to forecast when an asset might fail.

- Maintenance activities are scheduled proactively to reduce the risk of downtime.

Predictive maintenance not only extends the lifespan of assets but also ensures that maintenance is only done when necessary, making resource allocation more efficient.

Leveraging Data for Better Asset Management

To achieve operational excellence, businesses need to embrace data-driven asset management. This involves using technology to gather large amounts of data from different sources – such as equipment sensors, operational systems, and user inputs – to:

- Identify trends and patterns that impact asset performance

- Make well-informed decisions about which maintenance tasks should take priority and where resources should be invested

- Optimize the cost-effectiveness of each asset throughout its life cycle

By analyzing this data, organizations can gain valuable insights that help them make smarter choices about how they manage their assets.

The Role of Technology in Streamlining Processes

Technology solutions are instrumental in making both asset management and maintenance activities more efficient. These solutions empower organizations to:

- Reduce errors by automating manual tasks

- See the condition and performance of assets across different locations

- Improve long-term planning with reliable data analytics

With these tools, businesses have everything they need to maintain their assets with precision and ensure that resources are used effectively to achieve their operational objectives.

The Importance of a Complete Asset Maintenance Plan

Asset management is a vital part of how organizations work. It ensures that physical assets are always performing their best throughout their lifespan. One crucial aspect of asset management is having a well-thought-out plan for maintenance. This plan plays a significant role in keeping assets healthy and functional. In this section, we will look at why such a plan is necessary and how it can benefit an organization.

Understanding the Reasons Behind an Asset Maintenance Plan

1. Rising Repair Costs

- High repair costs often indicate ineffective asset management practices.

- Reactive maintenance (fixing issues only when they arise) can lead to small problems becoming bigger and more expensive to fix.

- These costs include not just the direct expenses of repairs but also the losses incurred from asset downtime and reduced productivity.

2. Unplanned Downtime

- Unscheduled periods of asset downtime can be highly disruptive to operations.

- Every minute that an asset is not working as intended can result in financial losses, decreased customer satisfaction, and reduced competitiveness.

- An asset maintenance plan aims to prevent such situations by scheduling regular maintenance activities that help avoid unexpected equipment failures.

3. Ageing Assets

- As assets get older, they naturally experience wear and tear.

- This means that closer monitoring and more frequent maintenance interventions are necessary.

- Ageing assets often require specific maintenance strategies to ensure they continue running smoothly.

- Without a structured approach to managing these assets, organizations run the risk of sudden breakdowns that can negatively impact their operations.

4. Common Signs That Signal the Need for an Asset Maintenance Plan

There are several indicators that suggest implementing an effective asset maintenance plan would be beneficial:

- Escalating repair costs point towards inefficiencies in current maintenance methods.

- Regular equipment breakdowns indicate poor overall health of assets.

- Older infrastructure requires careful planning to balance performance with maintenance costs.

The Benefits of an Asset Maintenance Plan

Implementing a comprehensive plan helps address these challenges in the following ways:

- Establishing regular check-ups and inspections to catch potential issues early on.

- Setting up monitoring systems that can detect problems before they become major.

- Defining clear procedures for maintaining asset integrity over time.

By doing so, organizations can shift from being reactive to proactive when it comes to maintenance. This change allows them to better align their activities with broader business goals, leading to improved operational performance and cost control.

What Should an Effective Asset Maintenance Plan Include?

An asset maintenance plan should have the following components:

- Detailed schedules for routine inspections and servicing tasks tailored to each asset’s specific requirements.

- Clear assignment of responsibilities, ensuring that there are designated individuals or teams responsible for each task.

- Projected durations for each maintenance activity, providing a timeline for completion.

- Anticipated costs associated with the plan, allowing for budgeting and resource allocation.

Having these elements in place ensures that assets receive the necessary attention without causing disruptions to overall operations.

2. Impact of Inadequate Maintenance Practices on Business Operations

Unexpected Equipment Breakdowns

- Inadequate maintenance practices often culminate in sudden equipment failures.

- These unexpected breakdowns can halt production lines, leading to considerable downtime.

- Delays in product delivery or service provision can erode customer trust and diminish market competitiveness.

Operational Efficiency and Safety

- Consistently poor asset maintenance can precipitate a decline in operational efficiency.

- The wear and tear on improperly maintained assets typically require more energy and resources to achieve the same output.

- Employees face heightened safety risks when working with compromised equipment, which might also violate health and safety regulations.

Financial Health Implications

- A neglectful approach to asset maintenance usually results in escalated repair or replacement expenditures.

- Premature asset failure, necessitating unplanned capital outlays for new equipment, strains budgets and disrupts financial planning.

- The cumulative effect of these costs can be a critical blow to a company’s financial stability.

Repercussions on Business Operations

- Poor maintenance practices affect not just individual assets but the entire operational framework of an organization.

- Asset availability is compromised, leading to suboptimal business performance and potential revenue loss.

- The ripple effects of inadequate maintenance reverberate through all aspects of business operations, from product quality to employee morale.

By examining the benefits of a structured asset maintenance plan, businesses can underscore the necessity for proactive measures. Such measures not only safeguard against the immediate tangible impacts of asset failure but also fortify the organization against broader operational disruptions. Recognizing these imperatives is central to developing robust asset management strategies that align with overarching business objectives.

Developing and Implementing an Effective Asset Maintenance Plan

Crafting an effective asset maintenance plan is crucial in the field of asset management. This process involves strategic steps such as highlighting important assets, selecting the right maintenance strategies, monitoring asset performance, and prioritizing tasks.

1. Prioritizing Assets for Maintenance Activities

When creating a maintenance plan, the first step is to determine which assets should be given priority. Several factors come into play during this decision-making process:

- Criticality of Assets: Some assets are more vital to operations than others. For example, in a manufacturing plant, machinery directly involved in production may be considered more important than office equipment. Critical assets should always be given top priority in any maintenance plan.

- Consequences of Failure: The potential impact of an asset failing should also influence its prioritization. Assets whose failure would lead to significant operational disruption or safety hazards should be high on the maintenance priority list.

- Asset Age and Condition: Older assets or those already showing signs of wear and tear may require more frequent or intensive maintenance.

- Cost of Repair vs Replacement: If the cost of frequently repairing an asset outweighs the cost of replacing it, it could indicate that this particular asset should be a lower priority in the maintenance schedule.

Considering these factors can help organizations make informed decisions about where to allocate their resources most efficiently.

2. Highlighting Key Assets

The next step is to identify key assets within your organization that require special attention due to their importance or vulnerability. This process is known as asset highlighting. By using an Asset Register, you can categorize these highlighted assets based on their function, criticality, location, condition, and other parameters. This register serves as a quick reference guide for your maintenance team and allows you to track real-time data related to each asset’s status.

3. Choosing the Right Maintenance Strategy

Once you’ve identified and prioritized your assets, the next step is to select the right maintenance strategy for each one. This strategy should be tailored to the specific needs of the asset, taking into account its criticality, condition, and the cost-effectiveness of different maintenance approaches. Here are a few strategies you might consider:

- Preventive Maintenance: Regular inspections and maintenance tasks are performed to prevent asset breakdowns. This approach is suitable for high-value or critical assets where failure can lead to significant operational disruption.

- Predictive Maintenance: Predictive maintenance uses data analysis to anticipate when an asset may fail, allowing maintenance teams to intervene before this happens. This approach is useful when dealing with complex machinery where advanced warning of potential issues can prevent costly downtime.

- Reactive Maintenance: In some cases, it may be more cost-effective to repair or replace assets only after they fail. This strategy could apply to non-critical assets or those with lower replacement costs.

4. Monitoring Asset Performance

An effective maintenance plan isn’t static; it should evolve based on the ongoing performance of your assets. Implementing a Computerized Maintenance Management System (CMMS) can facilitate real-time monitoring of asset conditions, enabling your team to adjust maintenance schedules as needed and respond quickly to emerging issues.

By diligently prioritizing assets, highlighting key areas for attention, choosing the most appropriate maintenance strategies, and constantly monitoring performance, organizations can devise an effective asset maintenance plan that minimizes downtime, enhances operational efficiency, and prolongs the lifespan of their assets.

2. Selecting Appropriate Maintenance Strategies for Different Asset Types

Selecting the best maintenance strategies for different types of assets is crucial to ensure they last long. The strategy chosen should match the characteristics and performance requirements of the asset.

Preventive Maintenance for High-Risk Assets

Assets that have a high risk of failure or whose breakdown can cause major operational disruptions benefit from preventive maintenance. This approach involves scheduled inspections and routine tasks to prevent potential failures.

Predictive Maintenance for High-Value Assets

For high-value assets where unexpected failure can result in significant costs, predictive maintenance is used. By leveraging advanced technologies like IoT sensors and data analytics, predictive maintenance can anticipate issues before they occur, enabling timely actions to prevent breakdowns.

Here are some practical steps to follow in the process of creating a comprehensive maintenance plan for assets under management:

- Asset Highlighting: Identify and prioritize the assets based on their criticality, usage frequency, and failure implications.

- Maintenance Strategy Selection: Choose a suitable maintenance strategy depending on the nature of the asset and its operational importance.

- Asset Performance Monitoring: Implement regular monitoring of asset health using sensor-based technologies or conducting visual inspections. The collected data aids in making informed decisions regarding required maintenance actions.

- Resource Allocation: Allocate resources effectively according to the priority of assets and their maintenance needs.

- Maintenance Schedule Development: Develop a comprehensive schedule outlining when each asset requires maintenance based on its selected strategy.

Remember, consistency is key in maintaining optimal asset performance – from regularly tracking performance metrics using tools like a Computerized Maintenance Management System (CMMS), to carrying out planned repairs, every step contributes towards the longevity and effectiveness of an organization’s valuable assets.

3. Establishing Effective Asset Performance Monitoring Practices

Implementing strong monitoring processes to track the health of assets is an essential practice in asset management. It involves regularly checking and evaluating assets to catch any early signs of damage, so that maintenance can be done proactively to prevent bigger problems. Asset performance monitoring is crucial for keeping critical assets in good condition and working properly.

Key Steps for Effective Asset Performance Monitoring:

1. Asset Highlighting

- Start by identifying and prioritizing critical assets that could cause major issues if they break down.

- Keep an updated list of all assets using an asset register, organizing them based on their importance and role in the organization.

2. Maintenance Strategy Selection

- Choose a maintenance strategy for each highlighted asset that fits its job, how likely it is to fail, and how much it would affect overall productivity.

- Consider different approaches like regular check-ups, predicting when maintenance is needed, or using sensors to monitor the asset’s condition.

3. Asset Prioritization

- Create a system for ranking assets based on things like age, how often they’re used, how critical they are, and past performance data.

- This helps in using resources wisely and focusing on assets that need immediate attention.

4. Practical Steps to Follow in Creating a Comprehensive Maintenance Plan

- Set clear goals and standards for how well each asset should perform.

- Plan regular inspections and check-ups to see if there are any issues.

- Use sensor technology when possible to monitor assets in real-time and collect data automatically.

5. Performance Data Analysis

- Study the data collected to find any patterns or unusual things that could mean there’s a problem.

- Use this information to make decisions about what maintenance should be done and whether it’s better to upgrade or replace certain assets.

By following these principles for asset performance monitoring, organizations can not only make their assets last longer but also improve how well they work and keep everyone safe. It’s important to include these practices as part of the overall asset management plan, so that everything runs smoothly and meets the organization’s goals.

The next step in making asset management sustainable is using advanced technology solutions that work well with these established practices.

Conclusion

The integration of Sensemore’s AI and machine health monitoring into the realm of asset maintenance management brings about a significant change towards smarter, more efficient, and proactive practices. With these advanced technologies, organizations can shift from reacting to problems to anticipating and preventing them.

Data analysis plays a crucial role in this new approach, helping to shape maintenance decisions. By using detailed information about asset health, decision-makers can spot patterns, forecast potential issues, and schedule maintenance tasks before expensive breakdowns happen. This has two major benefits: improved asset performance and significant cost savings from avoiding emergency repairs and reducing downtime.

Using innovative technologies like AI not only improves the accuracy of machine health monitoring but also enhances an organization’s ability to optimize their asset management strategies. This technological capability provides a holistic understanding of the entire operational system, ensuring that each part functions at its best and contributes to overall efficiency.

Effective asset management is essential for businesses that want to maintain performance, reliability, and value from their investments. It requires taking a comprehensive approach that combines technology, strategic planning, and data-driven decision-making. This synergy is key to balancing operational needs with long-term asset sustainability.

To stay ahead in asset maintenance management, organizations should explore the AI-powered solutions offered by Sensemore. These solutions demonstrate the transformative power of innovation in modern asset management—making sure that assets remain relevant in the future business landscape.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…