For many years, machine tools have been the backbone of many manufacturing industries. Machine tools also play an important role in the global economy nowadays. These machines, which transform complex designs into products by processing materials of different hardnesses, need to be maintained for performance, quality, and ultimately profit.

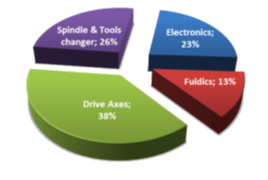

The spindle unit of CNC lathes affects the reliability, overall production efficiency, and stability of the machine. During machining, the spindle is subjected to extreme loads and thermal conditions. Cutting forces transmit, in form of static and dynamic, through the tool system to the spindle bearings. Issues in the spindle are one of the main sources of downtime for CNC lathes in the manufacturing industry. According to a study conducted in Germany where maintenance information was collected from 250 machine tools in the automotive industry, there are four main reasons that cause machine tools stoppages. Among these, spindle and tool changer equipment malfunctions cause 26% of downtime. And as seen in the graph, this is the second biggest issue after drive axle failures. Due to the high cost of spindle downtime, it is common practice in the manufacturing industry to have a spare spindle for critical machine tools in the production system. By this means, a defective spindle can be quickly replaced and sent to a spindle repair shop. This minimizes repair time and therefore non-production cost.

Fig. 1 Machine Fault Types

Considering that machine tools are the most productive equipment of manufacture, it is expected to make them operate at their maximum capacity and avoid production losses caused by unplanned repair costs, downtime, or quality problems. Thus, keeping them in optimum condition is a priority in highly efficient production systems. This situation can be achieved through a preventive maintenance strategy for critical components of the machine tool. Thanks to this strategy, the maintenance task can be pre-planned according to the actual maintenance need of the equipment. For this reason, a decent maintenance plan which includes condition monitoring for spindles becomes important to reduce downtime and total cycle cost, and to increase the service life of the machine tool.

Condition Monitoring on Spindles

In condition-based monitoring, there are several monitoring techniques to monitor possible failure conditions of components. Among these, oil analysis, thermography, ultrasonics, and vibration are the most common. Each of these techniques has different abilities to predict startup failure. As we mentioned in the P-F curve in our previous blog on condition monitoring, malfunctioning machines can signal failure with increased vibration levels before contaminant particles on the oil are detected. Thanks to its versatility and reliability, vibration analysis as machine tools has become one of the most accepted and used for rotary equipment. Vibration monitoring detects deteriorations such as wear, imbalance, misalignment, and fatigue in parts that are under rotational or reciprocating motion.

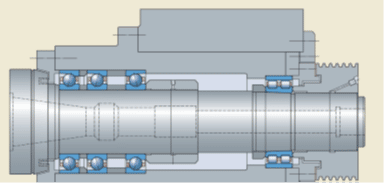

Fig. 2 CNC Lathe Spindle

Machine tool spindles are complex delicate assemblies with a considerable number of components. Each of them plays a vital role in the functionality of the spindle. The individual performance of the components contributes to a certain extent to the overall performance of the spindle. Bearings in machine tool spindles are the most sensitive component in practice. Consequently, any major issues are usually reflected and detected through the bearings. Most of the time, other issues affect the performance and working life of bearings. Therefore, bearing issues are the most common malfunctions encountered in the spindle.

Roller bearing life (L10) is a nominal calculation at the design stage that does not take all factors, which may affect the bearing life, into account. Due to various static and dynamic loads such as working at variable speeds, lubrication conditions, vibrations generated during machining, unbalance and assembly tolerances, roller bearing life ends before the calculated cycle. Therefore, periodic maintenance of the spindles is of utmost significance in order to prevent crucial stoppages and high damage to the machine.

Case Study

As we have just explained above, monitoring the condition of the spindles has great importance for CNC machines. In the industry, such studies are usually carried out every three or four months, or the equipment health is monitored with the built-in temperature sensors in the grinding wheel spindle. Nevertheless, such maintenance strategies can have costly consequences for the long haul. Therefore, condition-based maintenance is the most effective method for achieving maximum performance. At this point, applications in the industry monitor systems by taking measurements at certain time intervals. This technique does not constitute a very applicable process as it is not known whether the CNC machine is working during those time intervals or not. Besides, parameters that vary according to the application such as fly cutters, machining surface, and rotation speeds also make the situation even more chaotic. Sensemore solves this problem with the Trigger device. Trigger sends the measurement order to the sensor by transmitting the 5V signals to the receiver with a code to be returned at the end of each process. Thus, it can monitor the vibrations of a CNC lathe in the grinding wheel spindle at the end of each machining and in a way that the parameters remain the same in every measurement.

As we stated above, various factors such as working at variable speeds, different types of machining tools, and materials change the vibration characteristics that may occur in the grinding wheel spindle. It would be inaccurate to make inferences about the machines’ health from these measurements. For this reason, operating the grinding wheel spindle at a constant speed for a short time at the end of each machining and taking vibration measurements during this process will create a correct trend as it is within certain boundary conditions. At this point, thanks to the code added to the CNC lathe, it sends a 5V signal to the Sensemore Trigger device after each part is machined. Sensemore Trigger gives the measurement order by triggering the Wired with the signal it receives. The whole process is completed in as little as five seconds and analyzes are performed on the Sensemore cloud application.

Nowadays, the human factor in the industry continues to decrease gradually due to advancing technology, and all manufacturing, maintenance, and quality processes are carried out in an automated manner. Vibration measurements, especially in maintenance and quality control processes, are starting to keep up with this technology. Otherwise, vibration measurements create a critical loss of labor and time. Sensemore, thanks to the portable accelerometers, application-specific hardware, and cloud-based analysis program they developed, offer easier and more reliable maintenance and quality control processes.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…

Discover Our Products

Sensemore Condition Monitoring Solution

If you enjoyed this blog, explore our Condition Monitoring Solution page.