In manufacturing, one of the crucial metrics used in this pursuit is Overall Equipment Effectiveness (OEE). OEE serves as a comprehensive measure of equipment performance, providing insights into how well equipment is utilized, how effectively it operates, and where improvements can be made. This introductory sheet aims to elucidate the concept of OEE, its significance, and the calculations involved.

Understanding Overall Equipment Effectiveness (OEE)

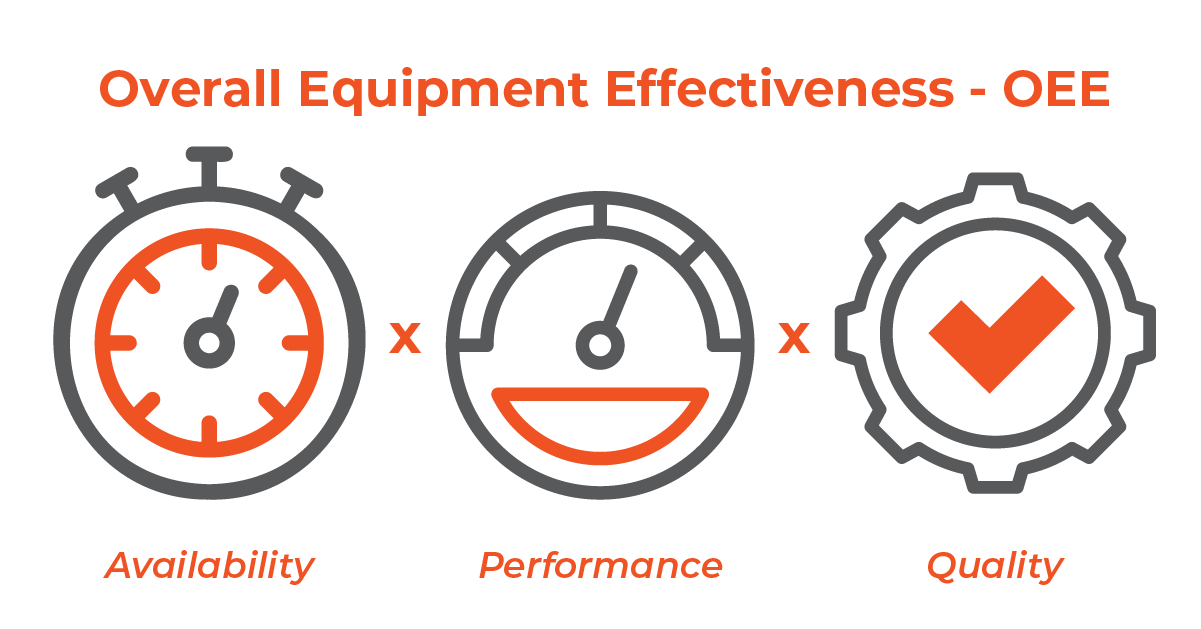

Overall Equipment Effectiveness (OEE) is a metric used to evaluate the performance of manufacturing equipment in terms of its efficiency and productivity. It provides a holistic view of equipment performance by considering three key factors: availability, performance, and quality. OEE enables manufacturers to identify areas of inefficiency, reduce downtime, enhance productivity, and ultimately improve the bottom line through predictive maintenance and condition monitoring solutions.

Components of OEE

- Availability: Availability refers to the percentage of time that equipment is available for production during scheduled production time. It takes into account factors such as equipment breakdowns, changeovers, and planned maintenance. Maximizing availability involves minimizing downtime and ensuring that equipment is operational when needed. Techniques such as Failure Mode and Effect Analysis (FMEA) and online condition monitoring can be used to identify potential failure points and enhance equipment reliability.

- Performance: Performance measures the speed at which equipment operates relative to its optimal speed. It accounts for factors such as slow cycles, idling, and minor stoppages that affect the overall speed of production. Improving performance involves identifying and addressing bottlenecks, optimizing workflows, and maximizing equipment throughput. Implementing industrial condition monitoring and predictive maintenance sensors can significantly contribute to identifying performance issues early on.

- Quality: Quality evaluates the percentage of good-quality products produced relative to the total output. It considers defects, rework, scrap, and other quality-related issues that impact product integrity. Enhancing quality involves implementing quality control measures, reducing defects, and maintaining consistency in production processes. Using asset maintenance systems can support quality improvement efforts by ensuring equipment is maintained to optimal standards.

OEE Calculations

OEE is calculated by multiplying the three components—availability, performance, and quality—together. The formula for calculating OEE is as follows:

OEE = Availability x Performance x Quality

- Availability CalculationAvailability = (Operating Time – Planned Downtime) / Operating Time

- Performance CalculationPerformance = (Ideal Cycle Time x Total Count) / Operating Time

- Quality CalculationQuality = Good Count / Total Count

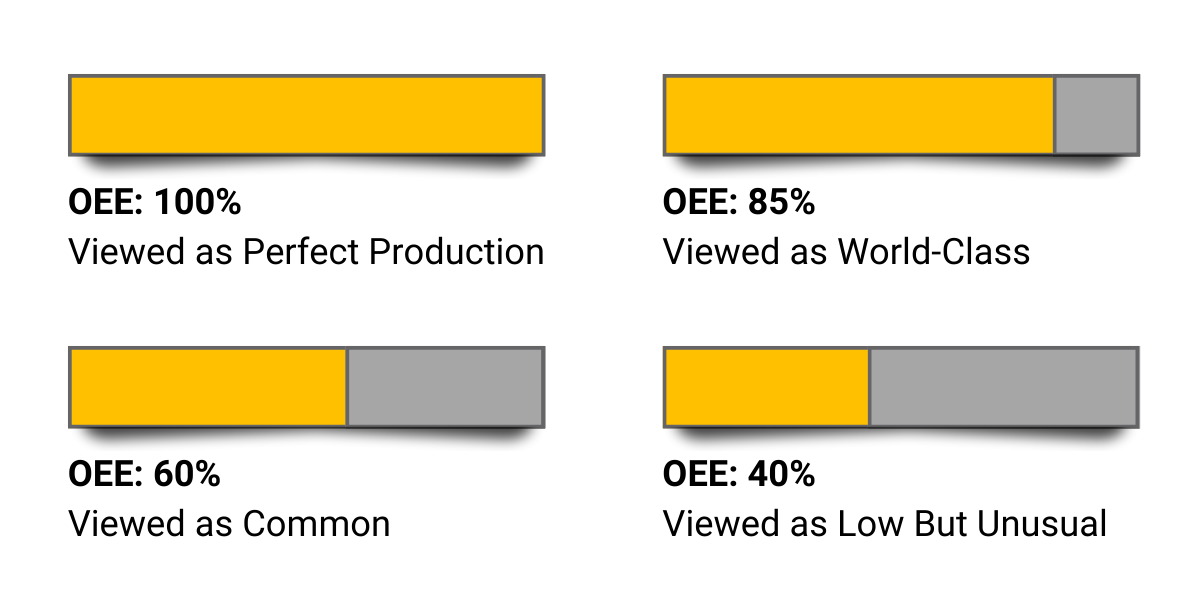

Interpreting OEE Scores

OEE scores range from 0% to 100%, with higher scores indicating better equipment performance and efficiency. Here’s how to interpret OEE scores:

- 100% OEE: Perfect performance, where equipment operates at maximum speed, without any downtime, and produces only good-quality products.

- 85% – 90% OEE: World-class performance, signifying highly efficient and productive equipment.

- 70% – 85% OEE: Good performance, with opportunities for improvement in availability, performance, or quality.

- Below 70% OEE: Indicates significant room for improvement, with potential issues in availability, performance, or quality that need to be addressed.

Benefits of OEE

- Performance Measurement: Overall equipment effectiveness provides a comprehensive and standardized method for evaluating equipment performance, allowing manufacturers to track progress and identify areas for improvement.

- Downtime Reduction: By pinpointing sources of downtime and inefficiency, OEE helps reduce unplanned downtime, optimize maintenance schedules, and enhance overall equipment availability. Integrating predictive maintenance applications can further help in preempting equipment failures.

- Increased Productivity: Improving OEE leads to higher productivity levels, increased throughput, and ultimately, better utilization of resources and higher profitability.

- Continuous Improvement: OEE serves as a catalyst for continuous improvement initiatives by fostering a culture of accountability, data-driven decision-making, and process optimization.

Conclusion

In conclusion, Overall Equipment Effectiveness (OEE) is a vital metric that enables manufacturers to assess equipment performance, identify areas of improvement, and enhance operational efficiency. By understanding the components of OEE and how it is calculated, organizations can streamline production processes, minimize downtime, and maximize productivity. Embracing OEE as a key performance indicator, alongside predictive maintenance solutions, industrial condition monitoring, and asset maintenance systems, empowers manufacturers to stay competitive, adapt to changing market demands, and drive sustainable growth in today’s dynamic manufacturing landscape.

Recommended Blog Posts

September 4, 2023

Powerful Signal Analysis Tools for Vibration Analysis

Predictive maintenance, crucial for machinery reliability, heavily relies on vibration analysis. Techniques like FFT…

September 4, 2023

Rotating Machinery Vibration Analysis

Vibration analysis is a critical tool in various industries like manufacturing, power generation, and transportation.…

December 28, 2022

Fault Diagnostic Technique Using Machine Mode Similarity Analysis

AI can diagnose machine faults with vibration data but machine mode similarity analysis is an alternative, it uses…

September 15, 2022

Understanding Rotating Machinery Data

Machine data is generated by physical attributes and actions of machines, collected by sensors and analyzed for…

August 6, 2021

Envelope Analysis

Bearings are critical elements in rotating machines, they support radial and axial loads, and reduce friction. Real…

May 6, 2021

What is Cepstral Analysis?

Cepstral Analysis, a tool used to detect periodicity in frequency spectrum, can be useful in gearbox fault detection in…

October 9, 2020

How is Fault Detection Performed?

Vibration measurements and analysis, using multiple parameters, can identify developing problems in machinery before…

September 21, 2020

Parameter Selections in Vibration Measurement

Vibration measurements are used to determine the response of machines to forces and identify potential issues. It is…

September 4, 2020

What is Vibration Analysis?

Vibration analysis can be used to discover problems in machines and predict when they might fail. It can significantly…

Discover Our Products

Sensemore Predictive Maintenance Solution

If you enjoyed this blog, explore our Predictive Maintenance Solution page.